Sotek Engineering

Subcontract Machining

Looking For Top-Quality Subcontract CNC Machining?

Contact Us!

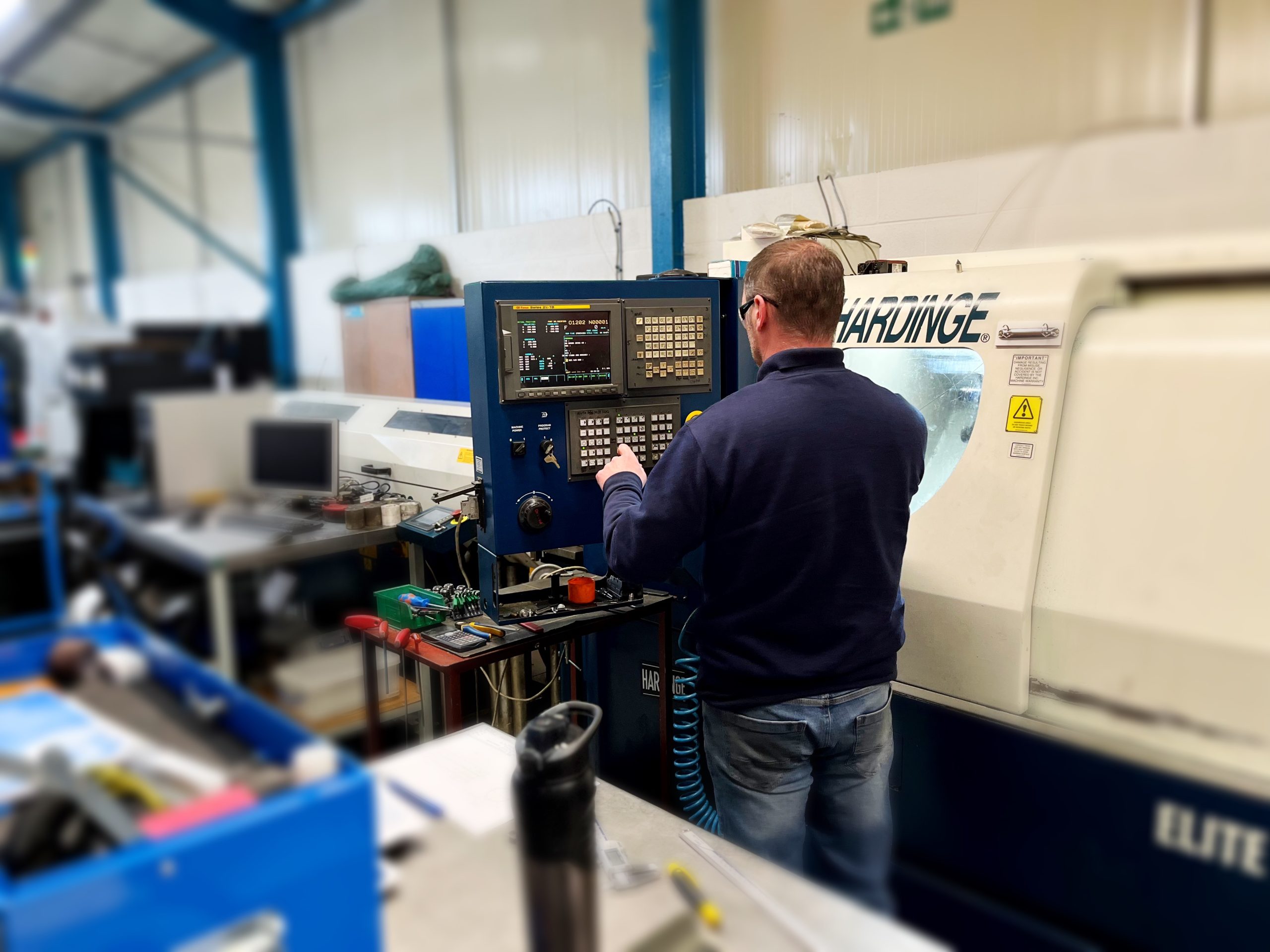

At Sotek Engineering, we specialise in providing high-quality subcontract CNC Machining Services for the manufacturing industry. We provide a wide range of CNC services to our clients, including CNC milling, CNC turning, and design for manufacturing.

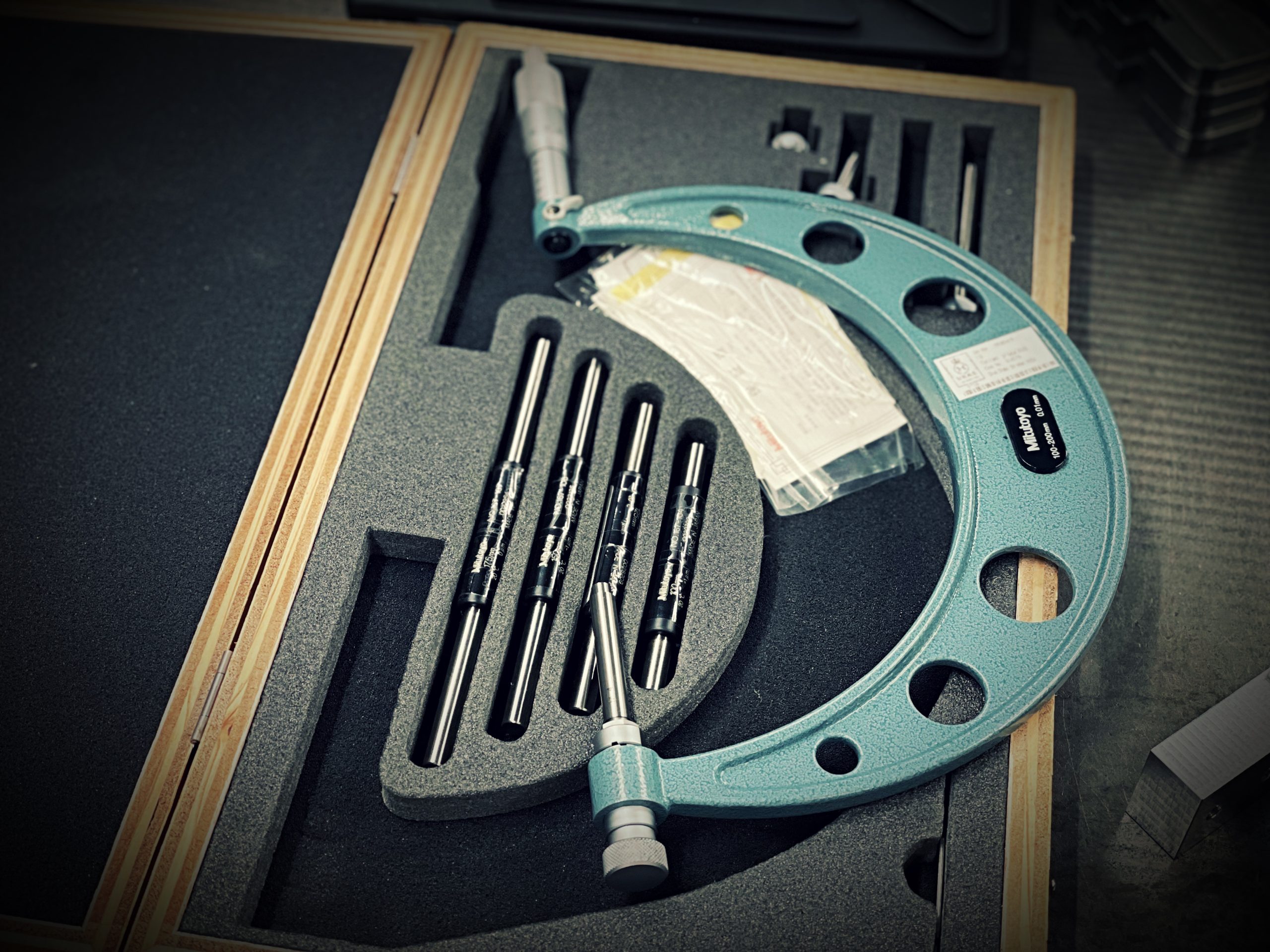

We are committed to achieving and maintaining exceptional quality control standards. By using ISO 9001-2015 compliant quality management systems, combined with routine inspections and statistical process control (SPC), we ensure superior quality results for all our valued clients!

Our rigorous quality control has earned us our reputation as a trusted supplier of CNC Machining Services for a wide range of industries, including Automotive and Motorsport, Medical, Oil and Gas, Aerospace and Defensive, and Nuclear.

We are proud to be fully compliant with ISO 9001-2015 standards and thoroughly committed to delivering exceptional subcontracting services, every time!

What Is CNC Machining?

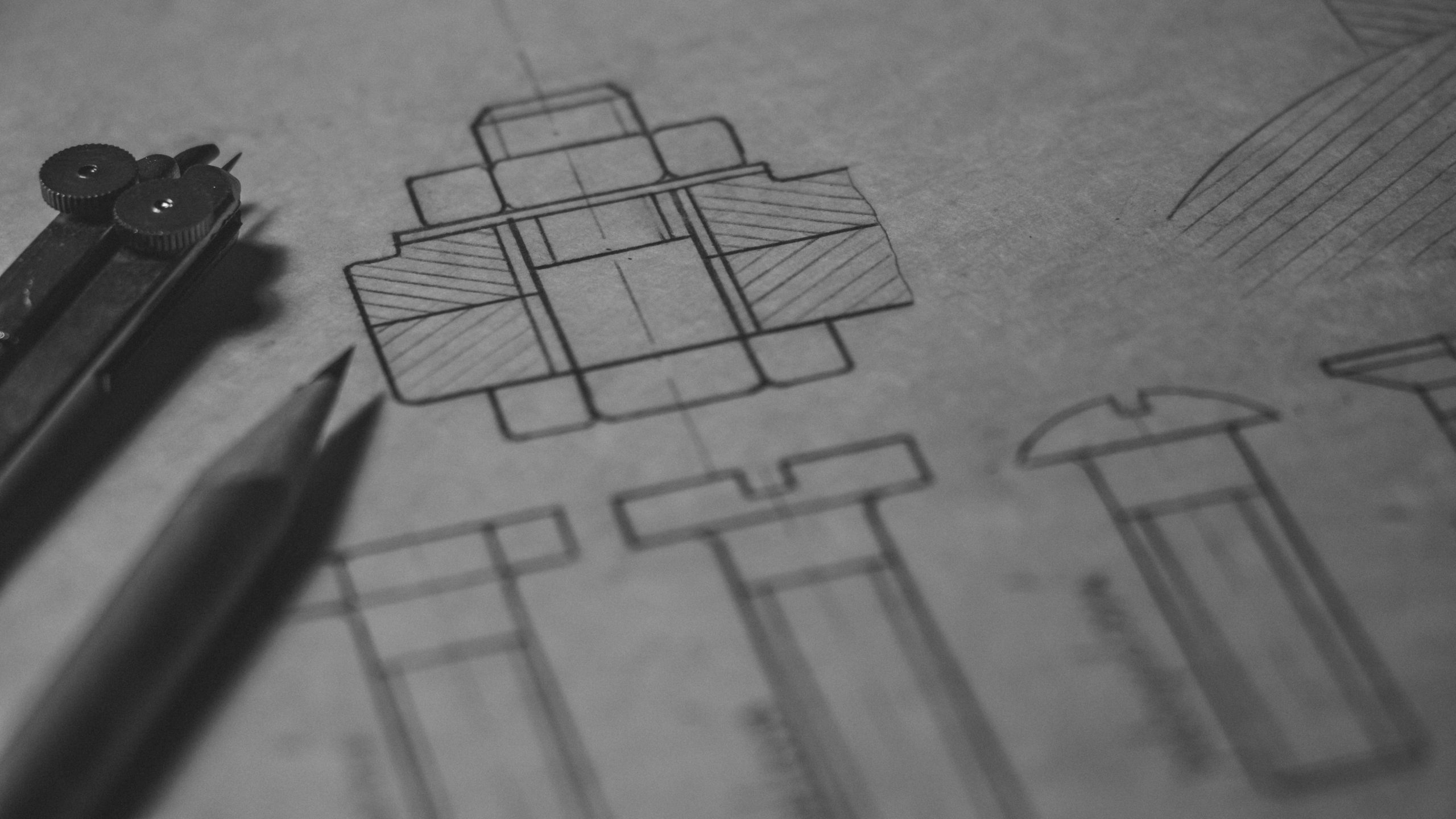

CNC machining is a set of manufacturing processes that are used to create a diverse range of products. CNC machining can be used to fashion products from a wide range of materials – including plastic polymers, metals, acrylic, and wood.

CNC machining is a subtractive process. In essence, this means that material is cut away from the base workpiece using a computer-controlled machine tool to achieve the desired result. CNC machining is suitable for complex and highly accurate parts, making it a popular choice for the manufacturing industry.

Two techniques are used in CNC machining: CNC Milling and CNC Turning.

The Two Types Of CNC Machining

CNC Milling

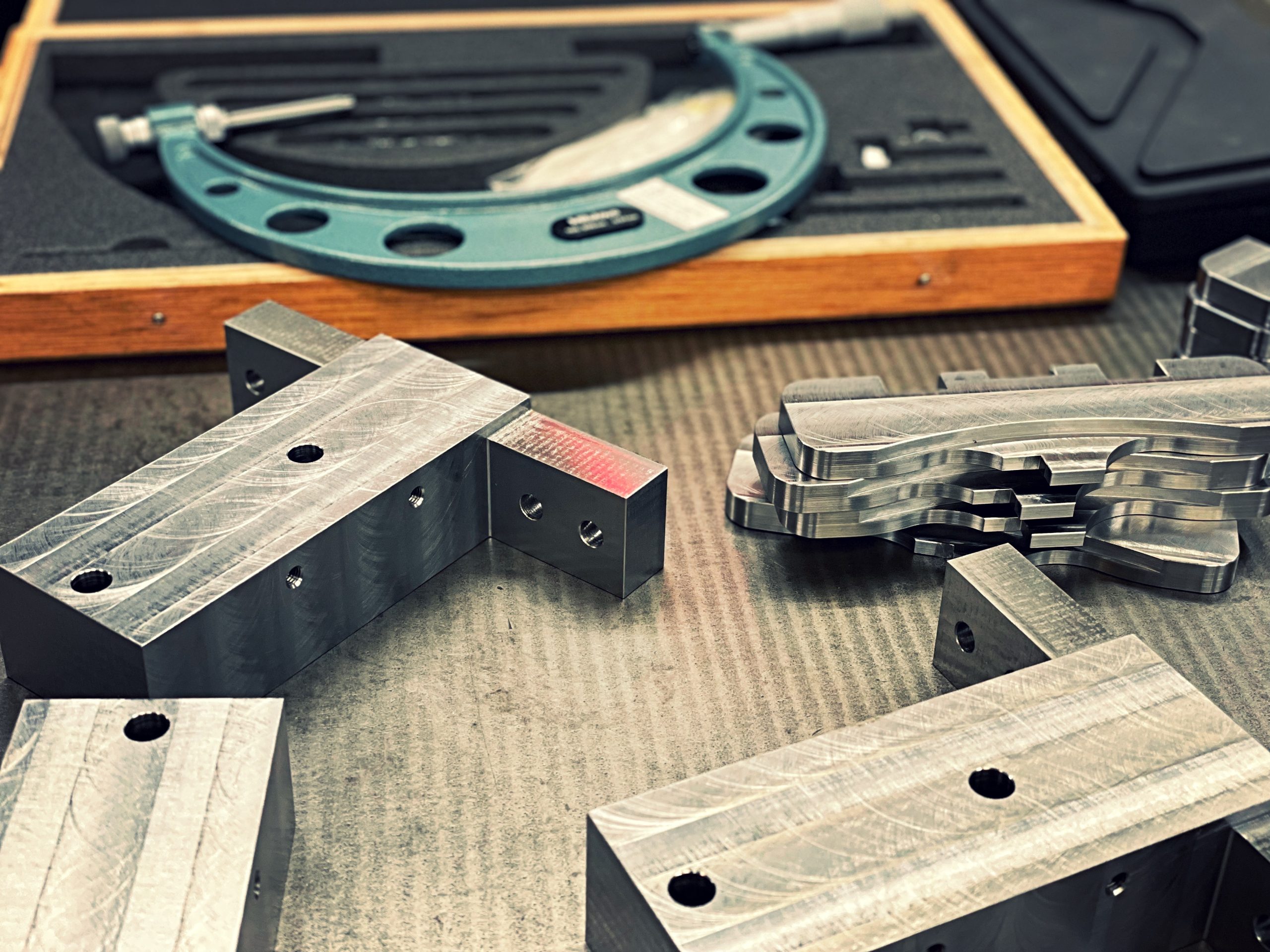

CNC Milling is a highly efficient and rapid manufacturing process that is used for achieving the mass production of products to high standards of precision at a fast turnaround rate.

The process uses a CNC machine-controlled rotating cutting tool to remove material from the workpiece, which is held in place on a worktable. The CNC machine cuts away material according to the design specification, running along multiple axes to create the correct shape.

This tool can be programmed to run along the X, Y, and Z axes, which gives the machine the ability to create complex shapes. The machine can create several features, including holes, slots, pockets, and contours, and can be used to create a wide range of shapes.

CNC Turning

The CNC Turning process involves fixing the workpiece to a rotating CNC lathe. The cutting tool removes the material until it creates the desired shape. This process is typically used for creating cylindrical shapes, while conical shapes can also be created using taper CNC turning.

The Advantages Of CNC Machining

CNC Machining is highly advantageous for the manufacturing industry for several reasons, including:

- Accuracy – CNC machining is more accurate than either plastic injection moulding or 3D printing. When used for prototyping, this ensures repeatable results for future production runs, delivering flawless consistency time and time again.

- Complex Designs – CNC machining is suitable for creating complex designs to high standards of accuracy. This is due to the CNC machine’s ability to run along multiple axes. CNC machines are even better at creating complex designs than 3D printing.

- Tight Tolerances – CNC machines are suitable for manufacturing products to tight tolerances, thanks to their accuracy. CNC machines are more effective at creating products to fine margins of error than plastic injection moulding or 3D printing, making them the smart choice for discerning manufacturers.

- Suitable For Plastics – CNC machining is suitable for making plastic products from a wide range of plastic polymers, including Plastic CNC Milling, including Delrin (POM), Nylon, Acrylic, Teflon (PTFE), Polyether (Peek) and Ultra-High Molecular Weight Polyethylene (UHMW).

- Reduction Of Defects – Using CNC machining processes significantly reduces defects in results compared with other manufacturing processes.

- Waste Reduction – Due to the reduction of defects, CNC machining also reduces waste. As a result, clients can make savings on their materials cost.

- Flexibility – CNC machining can create a wide range of shapes and complexities.

Our Commitment To Providing Top-Quality Subcontract Machining

At Sotek Engineering, we are committed to delivering exceptional results for our clients at cost-effective rates. We are dedicated to upholding high standards of quality control throughout all stages of our manufacturing processes, using ISO 9001-2015 compliant quality management systems and statistical process control alongside routine inspections.

We hold customer satisfaction paramount! We are proud to deliver exceptional customer support and guidance, cherishing our strong relationships with clients. We are proud to cater to the needs of high-profile companies in a wide range of industries, including Automotive and Motorsport, Medical, Oil and Gas, Aerospace and Defensive, and Nuclear.

About Our Subcontract CNC Machining Company

Established in 2017 by Steve Brown and Oliver Cumbers, Sotek Engineering is a trusted provider of CNC Machining services to a wide range of industries. Our experienced team harnesses state-of-the-art CNC technology, alongside rigorous quality control processes to deliver faultless products to our clients.

Sotek Engineering was created with a simple vision in mind – to meet the needs of UK businesses by delivering consistently high-quality machining, design, reverse engineering, and break-fix solutions. Our enduring commitment to achieving superior customer service has enabled us to form enduring professional relationships with our clientele.

We are conveniently situated in Newton Abbot, directly off the main arterial road which connects to the UK Motorway Network. This location facilitates same-day or next day deliveries of parts as required.

At Sotek Engineering, we offer a comprehensive range of subcontract CNC services, including:

- CNC Machining

- CNC Routing

- Design

- Reverse Engineering

- Re-Engineering

Check Out Our Testimonials!

Sotek Engineering was founded on a background of 15 years in the manufacturing industry.

Our proficiency in the creation of flawlessly finished CNC machined products has made us a trusted supplier to blue-chip clients in diverse industries, including Automotive and Motorsport, Medical, Oil and Gas, Aerospace and Defensive, Nuclear, and more.

Our results speak for themselves – we have served hundreds of satisfied clients from across a wide range of industries! To read some of our testimonials, click here.

Contact Us If You’re Looking For Subcontract Machining!

Contact Us If You’re Looking For Subcontract CNC Machining!

Let's get started with your next project...