Sotek Engineering

CNC Turning

CNC Turning

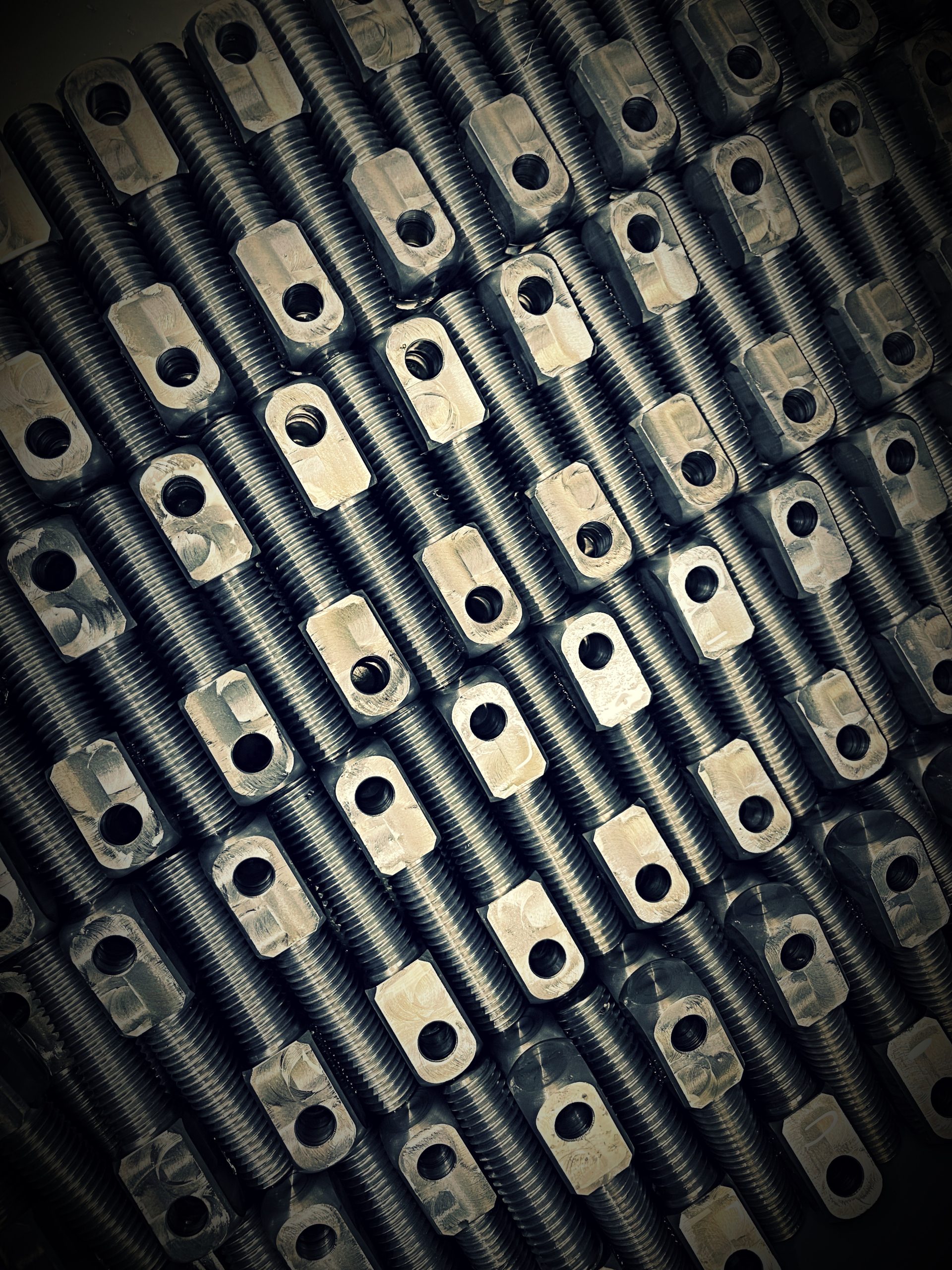

CNC turning is a machining process that involves the use of a computer-controlled lathe to produce cylindrical or conical parts by rotating a workpiece against a cutting tool. The cutting tool is held in a tool turret or tool holder, and the lathe machine moves the tool along the surface of the workpiece to remove material, resulting in the desired shape and dimensions of the finished part.

During the CNC turning process, the lathe machine can perform a variety of operations, including facing, drilling, threading, and grooving, among others. The process can be used to produce parts made from a variety of materials, including metals, plastics, and composites.

CNC turning machines are highly automated and can be programmed to produce complex parts with high precision and accuracy. The process is ideal for producing parts with symmetry or rotational features, such as shafts, cylinders, and cones.

Overall, CNC turning is an essential technology in modern manufacturing, as it allows for the production of high-quality parts with tight tolerances, complex geometries, and in large quantities, all while minimising production time and costs.

CNC bar feed and driven machinery are components of CNC turning machines that are designed to automate the loading and feeding of raw material into the machine, allowing for continuous production without manual intervention.

CNC Turning

The bar feeder is a component that automatically feeds raw material, such as metal bars or tubes, into the CNC lathe machine, allowing for the production of long, cylindrical parts without interruptions. The bar feeder holds multiple raw materials and feeds them into the machine as needed, eliminating the need for manual loading and increasing efficiency.

Driven tooling is another component of CNC turning machines that allows for the machining of complex features on the workpiece, such as holes and slots, by using rotating cutting tools that are driven by a motor. Driven tooling allows for multiple operations to be performed on the workpiece, such as drilling, tapping, and milling, without the need for additional machines or setups.

Combined with the automation provided by the CNC control system, bar feed and driven tooling can significantly increase production efficiency and reduce the time and costs associated with manual labor. Additionally, the use of bar feed and driven tooling can allow for the production of complex parts with high precision and accuracy, making CNC turning an essential technology in modern manufacturing.