Sotek Engineering

CNC Milling

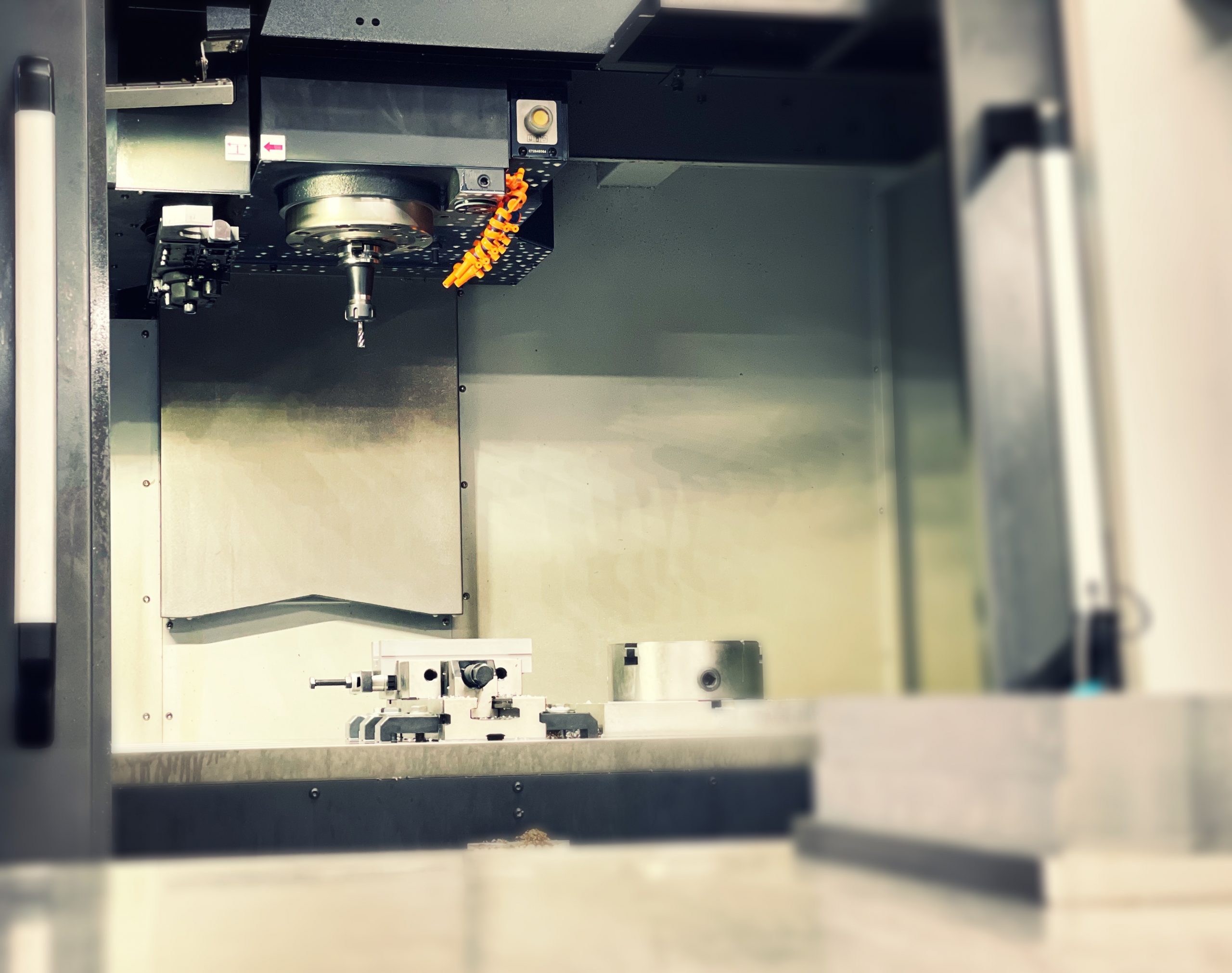

CNC Milling

CNC milling is a machining process that involves the use of a computer-controlled machine tool to produce precise, complex, and detailed parts from a variety of materials, including metals, plastics, and composites. The process involves removing material from a workpiece using a rotating cutting tool to create the desired shape and dimensions of the finished part.

During the CNC milling process, the workpiece is held in place on a worktable, and the cutting tool moves along multiple axes to remove material in a controlled and precise manner. The cutting tool can be programmed to move along the x, y, and z axes to produce complex shapes and features, including holes, slots, pockets, and contours.

CNC milling machines can be highly automated, with advanced software that allows for the programming of complex shapes and geometries with high precision and accuracy. The machines can also be equipped with a range of cutting tools, including end mills, drills, and taps, to perform a variety of operations on the workpiece.

CNC milling is a versatile and efficient process, capable of producing parts in large quantities and with high precision and accuracy. It is used in a wide range of industries, including automotive, aerospace, medical, and defence, among others. CNC milling is also highly customisable, allowing for the production of unique and innovative parts for specific applications.

CNC milling machines are computer-controlled machine tools that are used to produce precise, complex, and detailed parts from a range of materials, including metals, plastics, and composites. The machines are designed to remove material from a workpiece using a rotating cutting tool that moves along multiple axes, allowing for the production of complex shapes and features.

CNC Milling

There are several types of CNC milling machines, including:

Vertical milling machines: These machines have a vertical spindle that moves up and down, allowing for the cutting tool to move along the x and y axes.

Horizontal milling machines: These machines have a horizontal spindle that moves side-to-side, allowing for the cutting tool to move along the x and z axes.

5-axis milling machines: These machines can move the cutting tool along five axes, allowing for the production of highly complex and intricate parts.

Gantry milling machines: These machines have a fixed bridge that spans the workpiece, allowing for the cutting tool to move along multiple axes.

CNC milling machines can be highly automated, with advanced software that allows for the programming of complex shapes and geometries with high precision and accuracy. The machines can also be equipped with a range of cutting tools, including end mills, drills, and taps, to perform a variety of operations on the workpiece.

CNC milling machines are used in a wide range of industries, including automotive, aerospace, medical, and defence, among others, and can produce parts in large quantities and with high precision and accuracy. They are highly customisable, allowing for the production of unique and innovative parts for specific applications.