Sotek Engineering

Prototype CNC Machining

Looking For Top-Quality CNC Prototype Machining?

Contact Us!

Prototype Machining is a critical step in the product development process, transforming concepts into tangible prototypes. At Sotek Engineering, we provide advanced Computer Numerical Control (CNC) prototype machining services tailored to a wide range of industries.

With a commitment to precision, efficiency, and innovation, our team ensures that your prototypes are not only accurate representations of your designs but also functional models ready for testing and evaluation!

Understanding Prototype CNC Machining

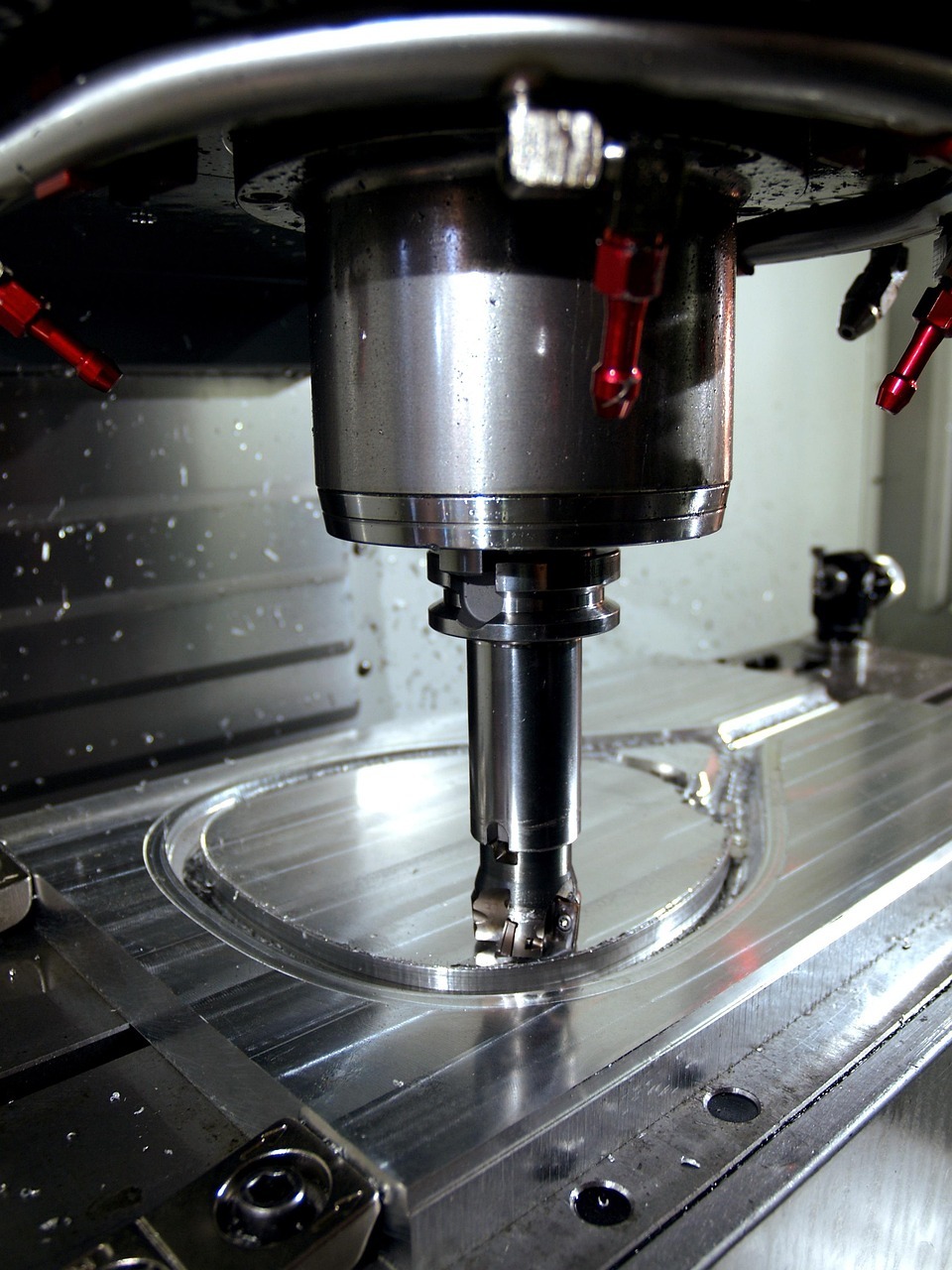

CNC prototype machining is a manufacturing process that utilises a computer-controlled machine tool to create parts from a digital model. This method allows for the production of highly accurate and complex components, making it ideal for prototyping purposes.

The process involves the following key steps:

1) Design Input: A digital 3D model of the part is created using CAD (Computer-Aided Design) software.

2) Toolpath Generation: The CAD model is converted into a set of instructions (G-code) that guide the CNC machine.

3) Machining: The CNC machine executes the instructions, removing material from a solid block to form the desired part.

4) Finishing: Post-machining processes, such as deburring and surface finishing, are applied to achieve the final specifications.

This approach offers several advantages, including high precision, repeatability, and the ability to work with a wide range of materials.

Our CNC Prototype Machining Capabilities

At Sotek Engineering, we use state-of-the-art CNC machinery and a team of skilled technicians to deliver prototypes that meet the highest possible standards.

Our capabilities include:

Material Versatility: We work with a broad spectrum of materials, including metals like aluminium, stainless steel, and titanium, as well as various plastics, enabling us to meet diverse project requirements.

Multi-Axis CNC Milling: Using 3, 4, and 5-axis milling machines, we can produce intricate geometries and complex features with exceptional accuracy.

CNC Turning: For cylindrical parts, our CNC lathes provide precise turning operations, ensuring tight tolerances and smooth finishes.

Rapid Prototyping: Our efficient processes allow for quick turnaround times, facilitating accelerated product development cycles.

The Benefits Of Our CNC Prototype Machining Services

Our CNC prototype machining services offers numerous benefits. These include:

Design Validation: The physical prototypes we create allow for thorough testing and validation, identifying potential issues before full-scale production.

Precision And Accuracy: Our advanced CNC machines and experienced operators ensure that each prototype is manufactured to exact specifications.

Cost-Effectiveness: By producing high-quality prototypes without the need for expensive tooling, we help reduce overall development costs.

Speed To Market: Our rapid prototyping capabilities enable faster testing and iteration, shortening time-to-market for new products.

The Industries We Serve

Our CNC prototype machining services cater to a wide range of industries, including:

Medical Devices: Crafting precision components that comply with regulatory requirements and are suitable for clinical applications.

Aerospace: Producing lightweight, high-strength components that meet stringent safety and performance standards.

Industrial Equipment: Creating robust components designed to withstand demanding operational conditions.

Consumer Electronics: Manufacturing intricate parts that require tight tolerances and aesthetic finishes.

Automotive: Developing parts that undergo rigorous testing for durability and functionality.

The Sotek Standard

Choosing Sotek Engineering for your CNC prototype machining needs will give your brand several key advantages over your competitors, including:

Customer-Centric Approach: We collaborate closely with clients to understand their specific needs and deliver tailored solutions that align with their objectives.

Quality Assurance: Rigorous quality control processes are implemented at every stage of production to maintain the highest standards.

Experienced Team: Our team comprises seasoned professionals with extensive experience in CNC machining and product development.

Advanced Technology: We invest in the latest CNC equipment and software to ensure cutting-edge capabilities and efficiency.

Why Choose Us For Prototype CNC Machining?

At Sotek Engineering, our CNC prototype machining services offer a reliable and efficient pathway from concept to functional prototype.

With our expertise, advanced technology, and commitment to quality, we empower businesses to bring their ideas to life with precision and confidence. Whether you’re developing a new product or refining an existing design, we are your trusted partner in the prototyping process.

For more information or to discuss your project requirements, please contact one of our expert advisors today. Together, we can bring your vision to life!

About Us

Founded in 2017 by Steve Brown and Oliver Cumbers, Sotek Engineering started with a clear mission: to deliver high-quality machining, design, reverse engineering, and repair solutions to businesses across the UK and beyond.

Since then, we’ve earned a reputation for being a trusted CNC turning partner across a wide range of industries. We combine advanced technology with strict quality standards and a strong focus on customer service to consistently deliver top-tier results.

Based in Newton Abbot, we’re ideally located near major transport routes, allowing us to offer same-day or next-day delivery when time is critical.

Our CNC services include:

- Reverse Engineering

- Re-Engineering

- CNC Routing

- CNC Milling

- Design

Let's get started with your next project...