Sotek Engineering

Outsourcing CNC Machining

Are You Considering Outsourcing CNC Machining?

Make Sure You Contact Us!

At Sotek Engineering, we’re the go-to experts to contact if you’re thinking of outsourcing CNC machining.

We specialise in high-quality sub-contract machining tailored to the manufacturing industry. Whether you need CNC milling, CNC turning, or design for manufacturing, we have the expertise and technology to bring your projects to life.

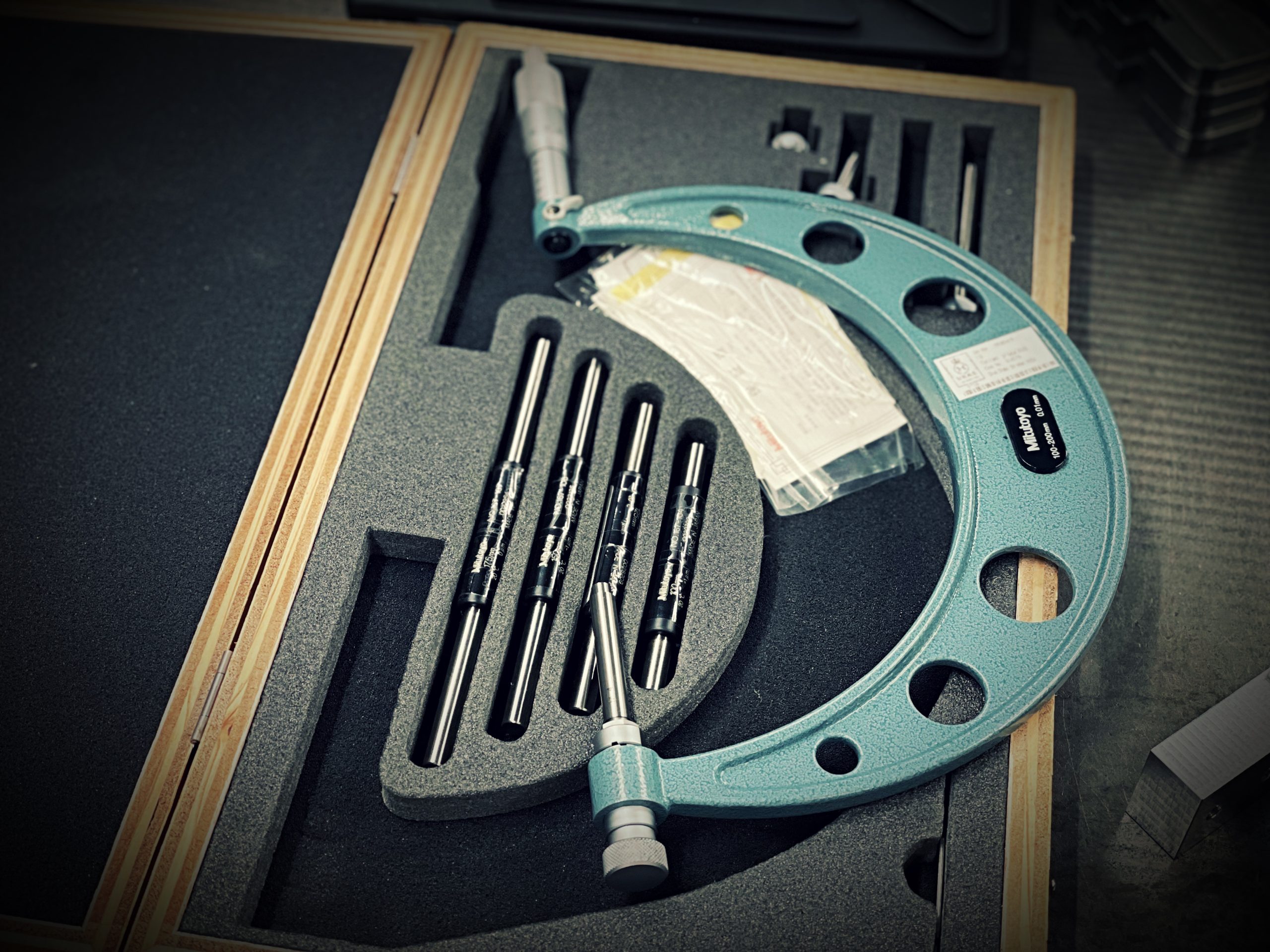

Quality is at the core of everything we do. We adhere to ISO 9001-2015 standards, using rigorous quality management systems, routine inspections, and statistical process control (SPC) to ensure precision and reliability in every component we produce. Our dedication to excellence has earned us a trusted reputation across industries like Oil & Gas, Aerospace & Defence, Automotive & Motorsport, Medical, and Nuclear.

With ISO 9001-2015 certification and a commitment to delivering exceptional results, we’re here to support your machining needs – on time and to the highest standards!

What Is CNC Machining?

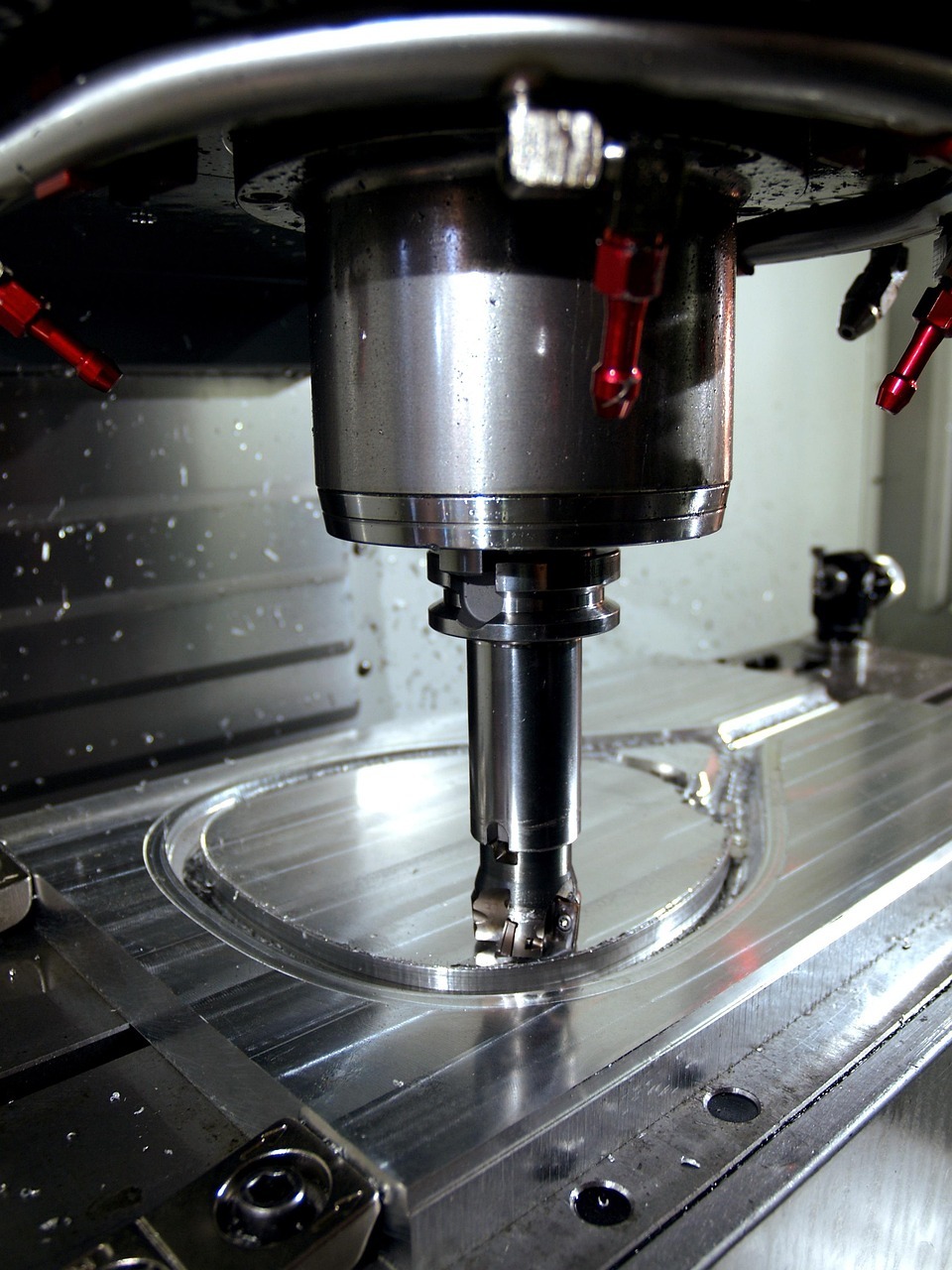

CNC machining is a highly versatile manufacturing process used to create products from materials like wood, metals, plastics, and acrylics.

This subtractive method works by carefully cutting away material from a base workpiece using computer-controlled machinery, allowing for high precision and intricate designs. It’s a popular choice across industries due to its accuracy and ability to handle complex designs.

The Two Types Of CNC Machining

There are two main types of CNC machining: CNC Milling and CNC Turning.

- CNC Milling is a quick and efficient process, ideal for mass production. It involves a rotating cutting tool controlled by a CNC machine that carves away material from a fixed workpiece. The cutting tool moves along multiple axes, which makes it perfect for creating detailed shapes like slots, holes, and contours.

- CNC Turning, on the other hand, uses a rotating lathe to hold the workpiece. The cutting tool then shapes the material into the desired cylindrical or conical form, making it perfect for creating precise cylindrical components.

Both methods offer incredible accuracy and are essential for crafting a wide range of parts with complex specifications.

The Advantages Of CNC Machining

CNC machining offers many great advantages for manufacturers. These include:

- Accuracy – CNC machining delivers superior precision compared to methods like plastic injection moulding or 3D printing, ensuring consistent results. This is especially valuable for prototypes and planned production runs.

- Tight Tolerances – The precision of CNC machining allows it to craft parts with tight tolerances, outperforming methods like injection moulding and 3D printing.

- Complex Designs – Thanks to its ability to move along multiple axes, CNC machining excels at producing intricate designs with high levels of detail. It can achieve far more precise results than 3D printing in this area.

- Plastic Compatibility – CNC machining works with a wide range of plastic materials, including Teflon (PTFE), Delrin (POM), UHMW, Nylon, and Acrylic, making it a versatile choice for creating plastic components.

- Defect Reduction – The process minimises defects, leading to higher-quality finished products compared to other techniques.

- Waste Reduction – By cutting down on defects, CNC machining also reduces material waste, offering cost savings for manufacturers.

- Flexibility – CNC machining is incredibly flexible, capable of creating a diverse range of shapes and designs to meet the specific needs of any project.

With these benefits, CNC machining is an invaluable option for manufacturers across a range of industries.

Outsourcing CNC Machining? Get In Touch!

At Sotek Engineering, our mission is straightforward: to deliver exceptional results to our clients at competitive prices!

Quality is at the heart of everything we do, and we maintain high standards throughout our manufacturing process. By using ISO 9001-2015 compliant systems and conducting regular inspections, we ensure that every product meets our rigorous requirements.

With customer satisfaction as our highest priority, we’re committed to providing outstanding support and guidance, while building strong, long-lasting relationships with all our clients.

About Us

Sotek Engineering was founded in 2017 by Steve Brown and Oliver Cumbers, who combined a skilled team, advanced CNC technology, and strict quality control to create an expert manufacturer.

We are located in Newton Abbot, just off a key road connecting to the UK motorway network, which is particularly convenient. It means we can offer a rapid turnaround – often delivering within the same or next day and being able to handle even the most urgent requests.

We offer a broad range of subcontract CNC services, including CNC Routing, CNC Machining, Design, Re-Engineering, and Reverse Engineering, all tailored to meet the diverse needs of our clients.

Our Testimonials

With more than 15 years of experience in the manufacturing industry, we’ve perfected the art of creating high-quality CNC machined products.

Our results speak for themselves – we have served hundreds of satisfied clients from across a wide range of industries! To read some of our testimonials, click here.

Contact Us If You’re Thinking Of Outsourcing CNC Machining!

Let's get started with your next project...