Sotek Engineering

Medical

Medical

CNC machining offers several advantages for the medical industry, making it an essential technology for producing high-quality medical components and devices. Some of the advantages of CNC machining within the medical industry include:

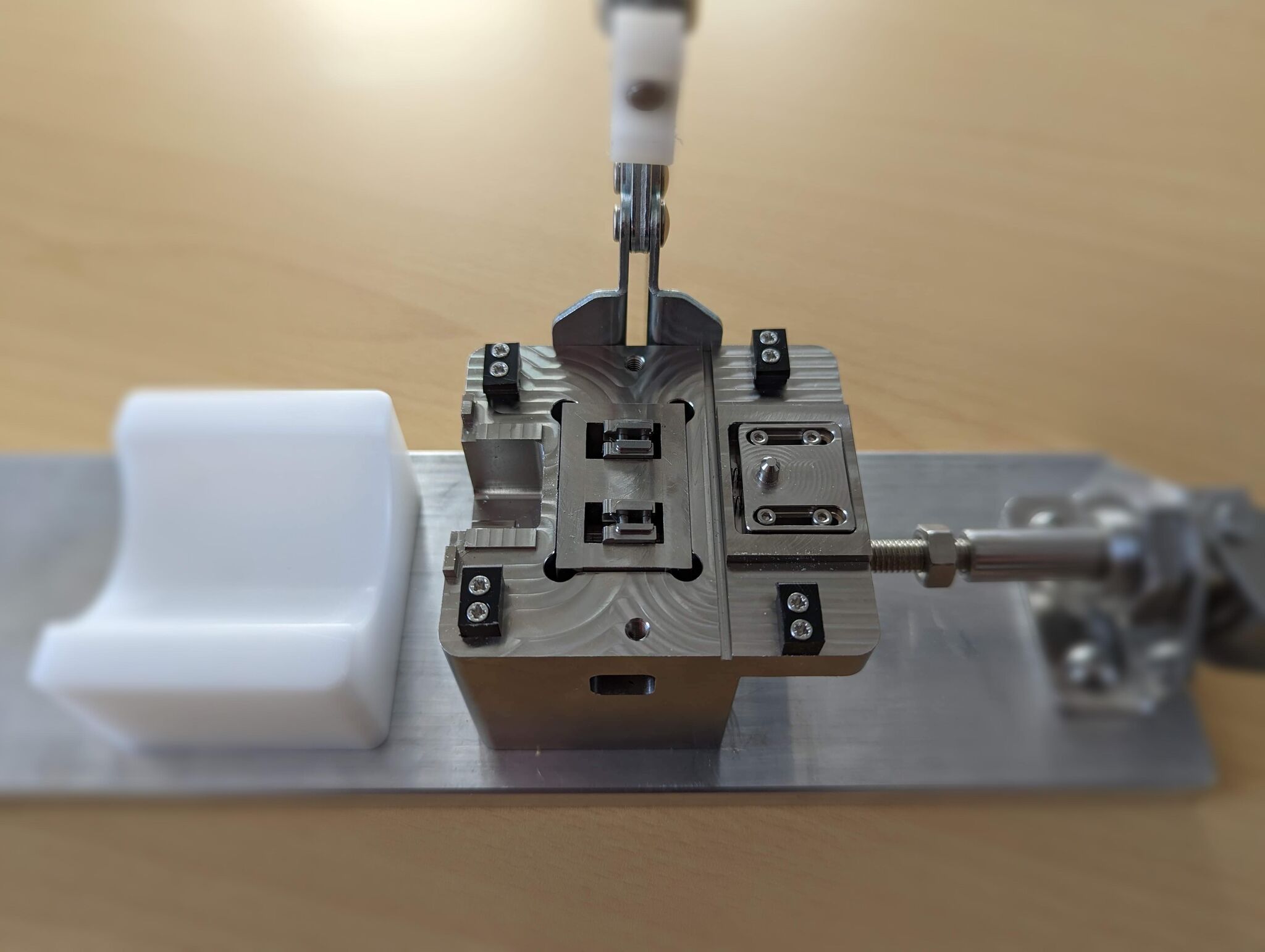

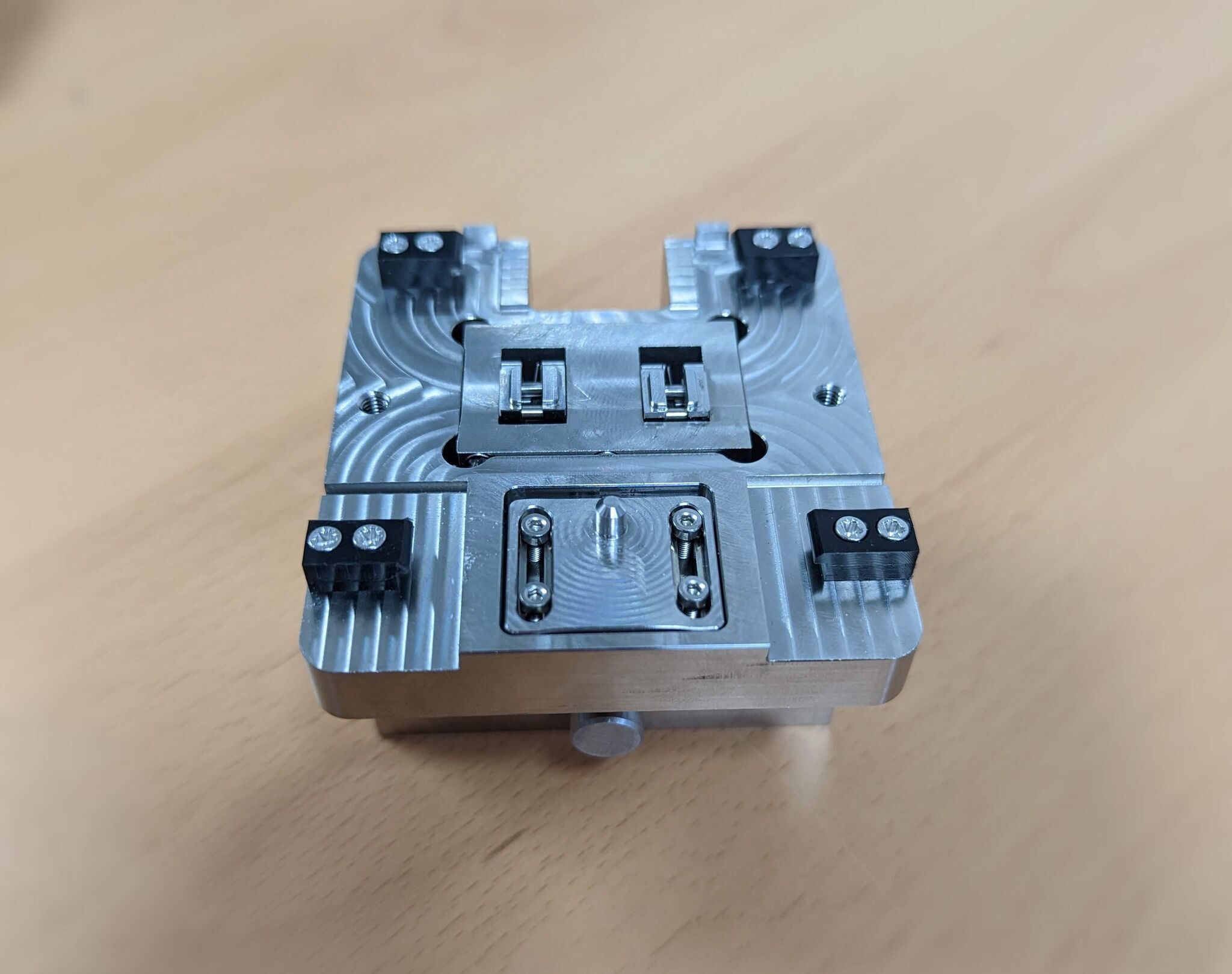

High precision: CNC machines can produce highly precise and accurate parts with tight tolerances, which is critical for producing medical devices that must meet strict specifications and quality standards.

Customisation: CNC machines can be programmed to produce custom parts and components for specific medical devices or applications, allowing manufacturers to produce unique and innovative medical products.

Versatility: CNC machines can work with a wide range of materials, including metals, plastics, and composites, which are commonly used in the medical industry. This versatility allows for the production of a wide range of medical components and devices.

Medical

Consistency: CNC machines can produce parts with a high degree of consistency, ensuring that each part is identical to the next. This consistency is critical for medical devices that must perform reliably and consistently over time.

Efficiency: CNC machines can operate continuously, reducing the time and labor required to produce parts. This can help to lower production costs and improve overall productivity.

Overall, CNC machining is an essential technology for the medical industry, allowing manufacturers to produce high-quality, precise parts quickly, efficiently, and with consistency, which is critical for the safety and performance of medical devices and components. CNC machining also offers the ability to customise parts and components for specific medical devices and applications, helping to drive innovation in the industry.