Sotek Engineering

Electronic Contract Manufacturing Services

Looking For Contract Electronic Manufacturing Services?

Contact Us!

At Sotek Engineering, we are proud to be a trusted provider of contract electronic manufacturing services (CEM), offering comprehensive support to original equipment manufacturers (OEMs) across a wide range of industries.

Our end-to-end manufacturing solutions allow our clients to concentrate on their core competencies—such as innovation, product development, and market growth—while we manage the technicalities of electronic manufacturing. From initial design support through to final assembly and testing, our CEM services deliver consistently high standards of quality, compliance, and customer service.

As demand continues to increase for high-quality, specialist manufacturing, we are well positioned to meet the needs of clients requiring reliable, low-to-medium volume production, particularly where projects involve complexity, customisation, or regulatory oversight.

A Fully Integrated Manufacturing Partner For Contract Electronic Manufacturing Services

At Sotek Engineering, we operate a vertically integrated business model. This enables us to oversee every aspect of the manufacturing process under one roof—from engineering support and prototyping to PCB fabrication, component assembly, box-build, inspection, and delivery.

For our customers, this results in a streamlined supply chain, improved communication, faster response times, and a higher degree of control throughout the life of a project.

Our integrated approach also includes design for manufacture (DFM) and new product introduction (NPI) support. By involving our engineering team at an early stage, clients benefit from expert advice on how to optimise product designs for reliable, efficient, and cost-effective production.

This proactive involvement significantly reduces the risk of redesigns, delays, or non-conformities later in the process.

Our Advanced Capabilities And Infrastructure For Electronic Contract Manufacturing Services

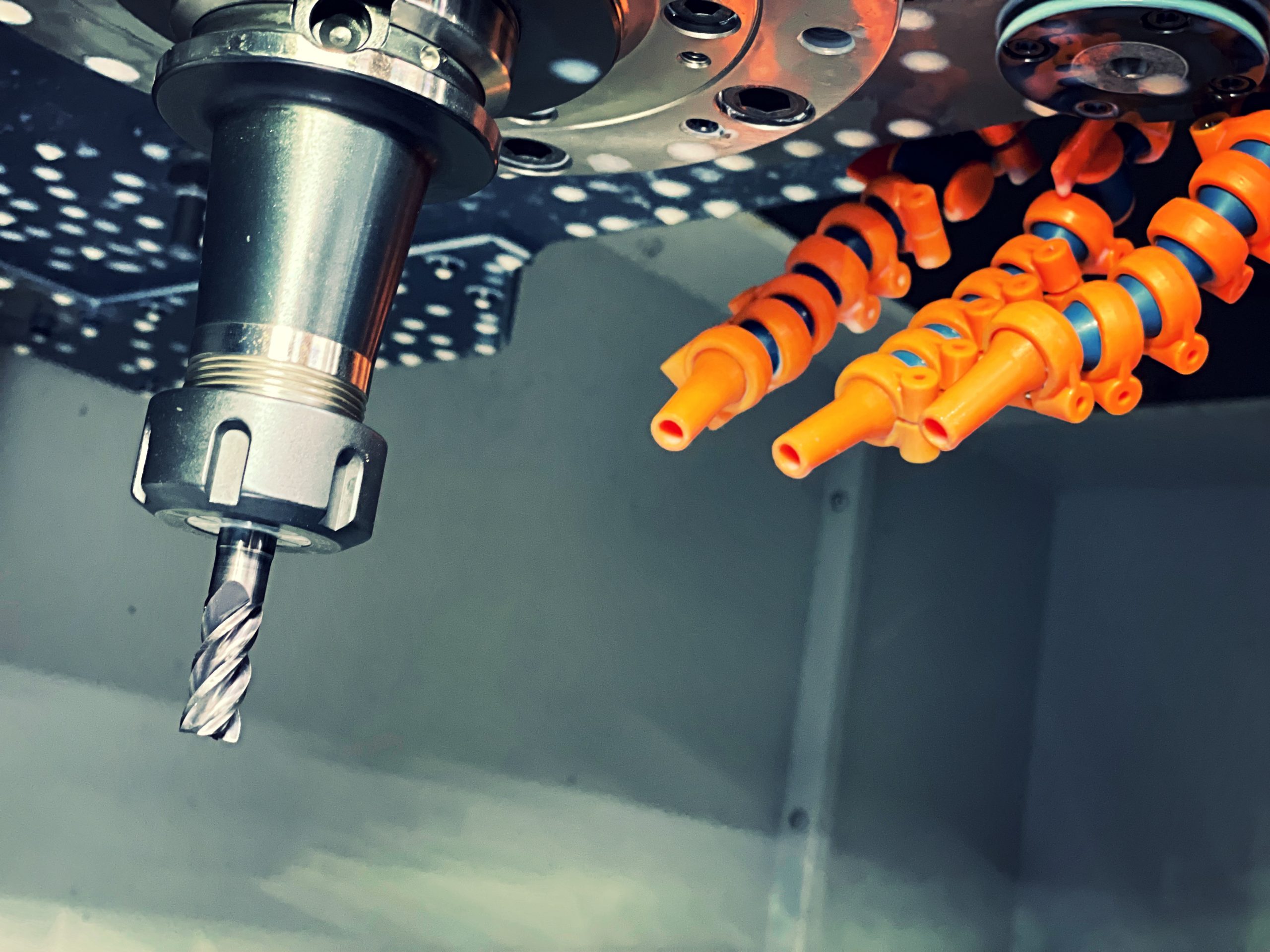

At Sotek Engineering, we are equipped to manage a wide range of manufacturing requirements, from simple PCB assemblies to complex, multi-layered boards with tight tolerances and high-density component placement. Our facilities support both flexible and rigid-flex PCBs, and are capable of handling fine-pitch surface mount assemblies, through-hole components, and mixed-technology builds.

Our production lines incorporate automated systems such as high-speed surface mount technology (SMT), 3D automated optical inspection (AOI), X-ray analysis for hidden joints, and selective soldering.

These technologies, combined with skilled technical staff and stringent process controls, allow us to deliver repeatable quality in every batch we produce.

In addition to core assembly capabilities, we offer a wide range of value-added services to support the reliability and functionality of the finished product. These include conformal coating, laser machining, component programming, rework services, and full electromechanical integration. Each of these services is managed in-house to maintain full oversight and quality assurance.

Quality Assurance And Compliance

Our commitment to quality is demonstrated by our adherence to internationally recognised standards. We operate under ISO 9001 and work to IPC-A-610 Class 2 and Class 3 standards, depending on the application.

We also have the capability to support clients requiring compliance with ISO 13485 for medical devices, AS9100 for aerospace, and full traceability in line with RoHS and REACH regulations.

Our internal quality control processes include multiple layers of inspection, testing, and validation. Every product undergoes thorough scrutiny, including optical inspection, X-ray testing, functional testing – and where required – in-circuit or environmental testing.

These procedures are tailored to each client’s specifications to ensure that the finished product is fit for purpose and compliant with all relevant standards.

Extended Support Throughout The Product Lifecycle

Beyond initial production, we offer comprehensive lifecycle support to ensure long-term product reliability and continuity.

Our aftermarket services include component-level repair, product refurbishment, calibration, and end-of-life planning. We also assist with sourcing alternatives for obsolete parts and can help modify designs to accommodate changes in supply chain availability.

This extended support allows our clients to manage risk more effectively, reduce waste, and extend the useful life of their products. It also provides a valuable resource for managing field returns, product updates, or changes in compliance requirements.

Proven Value For OEM Clients

By partnering with Sotek Engineering, our clients gain access to a professional and capable manufacturing team that understands the commercial, technical, and regulatory requirements of modern electronic products.

Our experience in managing complex builds, our rigorous quality management systems, and our commitment to customer service ensure that every project is delivered with precision and care.

We help our clients reduce capital expenditure by eliminating the need for their own production infrastructure. Our expertise in design optimisation and supply chain management contributes to cost savings, improved product reliability, and faster time to market.

For organisations developing specialist or regulated products, we provide the technical assurance needed to proceed with confidence.

Supporting Critical Applications Across Industries

Sotek Engineering is trusted by clients operating in some of the most demanding sectors.

In aerospace and defence, we deliver assemblies that meet stringent quality and environmental performance standards. In the medical technology sector, we support projects requiring traceability, regulatory compliance, and clinical reliability. We also support a wide range of industrial applications, from power electronics and process control systems to renewable energy, photonics, and automotive electronics.

This cross-sector expertise enables us to meet the needs of multiple key sectors, applying lessons learned across industries to improve outcomes for all our customers.

A Manufacturing Partner You Can Trust!

At Sotek Engineering, we aim to be a long-term partner in the future of your products. Whether you need early-stage prototyping, help with scaling up to production, or full lifecycle support, we have the infrastructure, expertise, and professionalism to meet your requirements.

If you are looking for a dependable and experienced contract electronics manufacturer, speak to our team about your next project. We will work with you to develop a tailored manufacturing solution that meets your technical, commercial, and strategic goals.

Contact Us If You Need Top-Quality Contract Electronic Manufacturing Services!

Contact Us If You Need Top-Quality Electronic Contract Manufacturing Services!

Let's get started with your next project...