Sotek Engineering

CNC Turning UK

Looking For Top-Quality UK CNC Turning?

Contact Us!

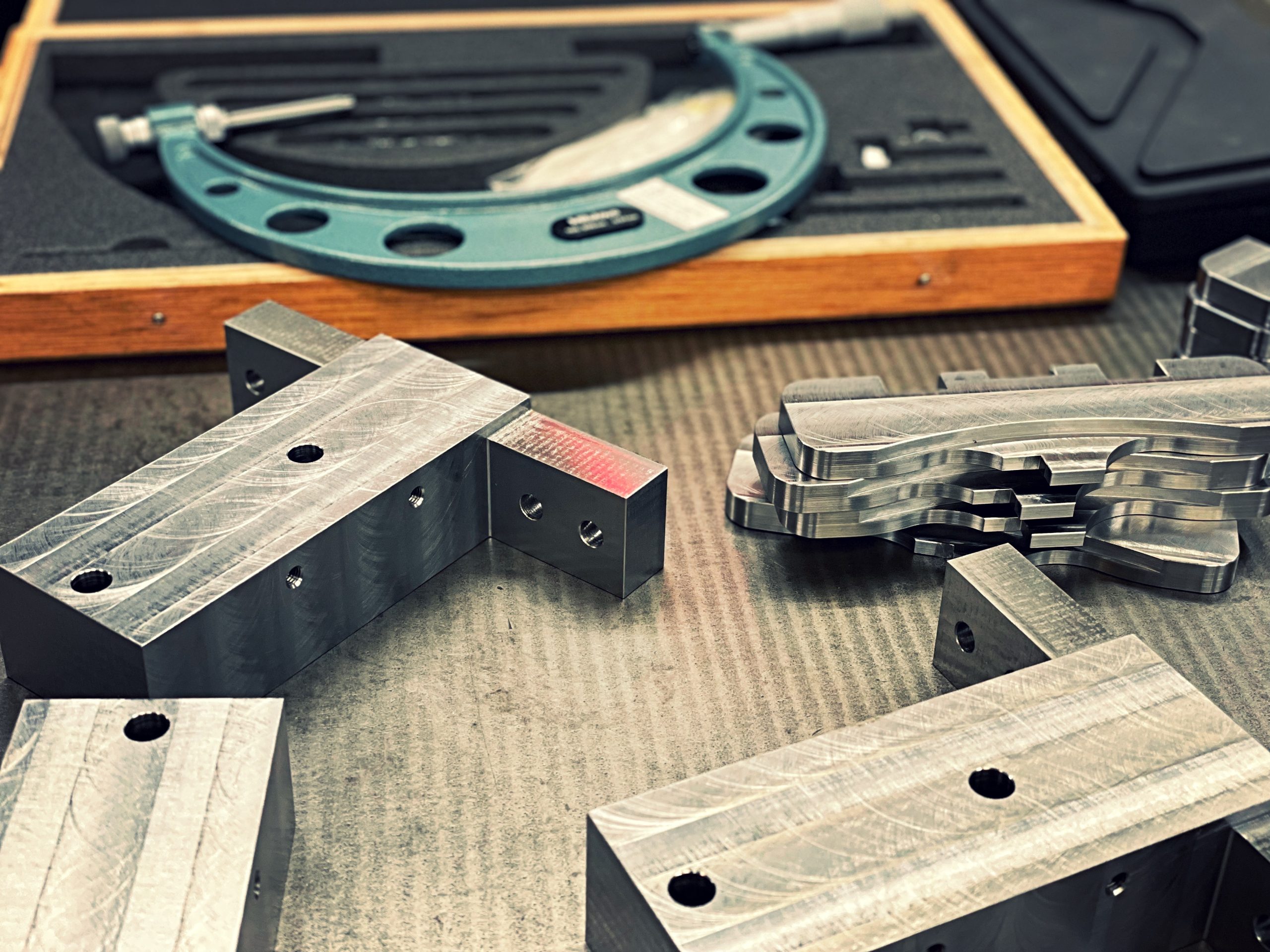

At Sotek Engineering, we specialise in CNC turning for a wide range of industries including Aerospace, Defence, Automotive, Motorsport, Medical, Nuclear, Oil and Gas, and more.

Our goal is to provide high-quality subcontract machining, design, reverse engineering, and break-fix solutions to our valued clients, while taking great pride in consistently delivering impeccable results and providing excellent customer service.

We employ cutting-edge technology to design and manufacture custom parts, achieving industry-leading outcomes. Our reputation as a trusted provider of CNC turning services across the UK and beyond has been earned through our dedicated adherence to stringent quality control and our steadfast compliance with ISO 9001:2015 standards.

What Does CNC Turning Involve?

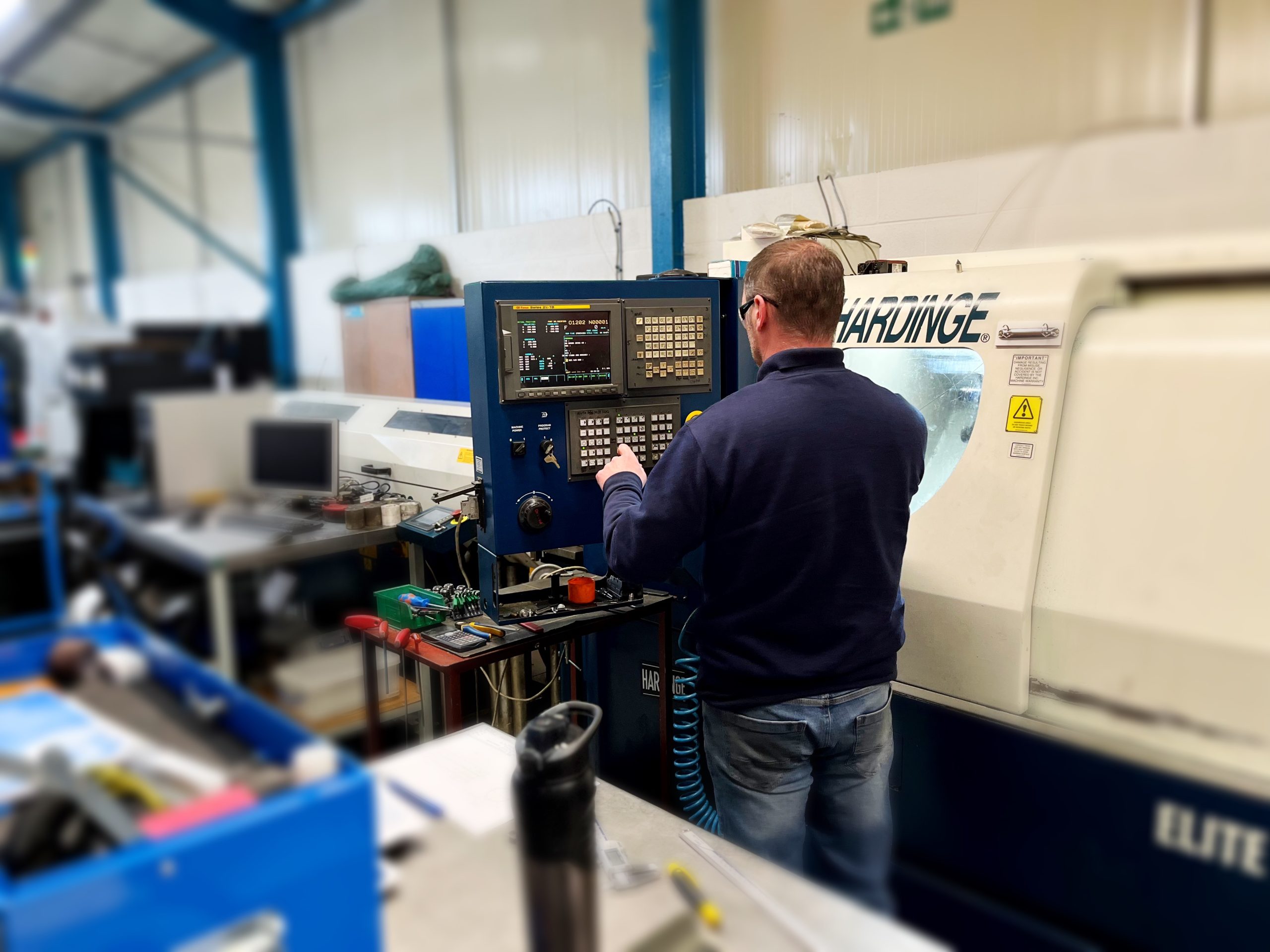

CNC turning companies offer precision machining services using Computer Numerical Control (CNC) turning machines. This advanced process involves computer-controlled tools shaping materials to craft precise cylindrical or rotational components with remarkable accuracy.

CNC turning machines are versatile, accommodating various materials from metals like steel, aluminium, and brass, to plastics and composites. The material choice is tailored to each client’s project requirements.

The precision, consistency, intricate detail, and customisability inherent in CNC turning make it the ideal method for producing components vital to various industries, including automotive, aerospace, medical, electronics, and more.

How Our CNC Turning Process Works

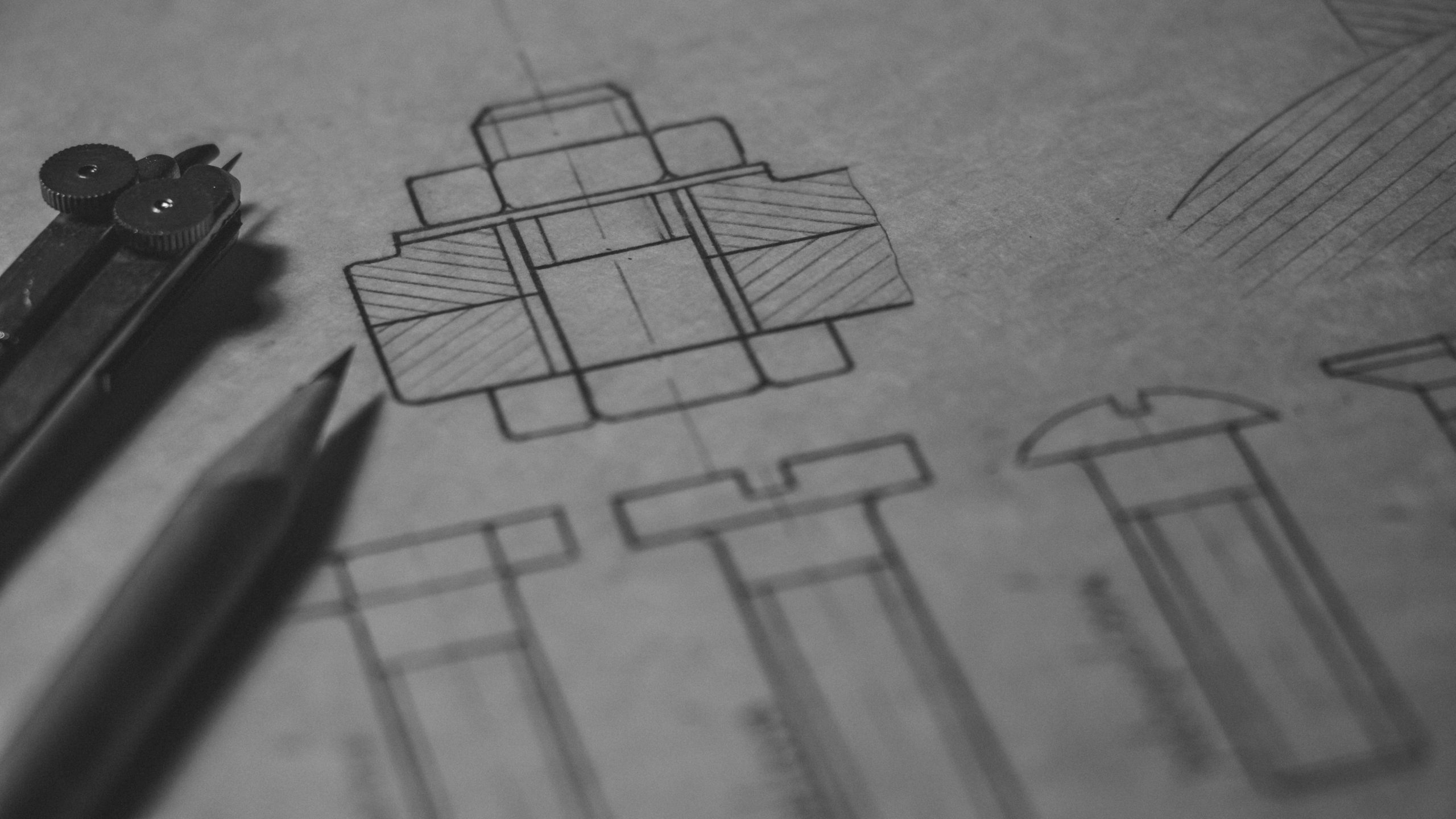

Prior to the start of the machining process, we engage closely with our clients to fully understand the design and specifications of the parts they desire.

Subsequently, we develop a CNC program that serves as the guiding blueprint for the CNC machine, instructing it on how to cut and shape the chosen materials to exacting specifications.

Setting up the CNC turning machine involves several key steps. First, we secure the workpiece firmly in the chuck and load the appropriate cutting tools into the tool turret. Then, we meticulously calibrate the machine to ensure precise positioning and alignment.

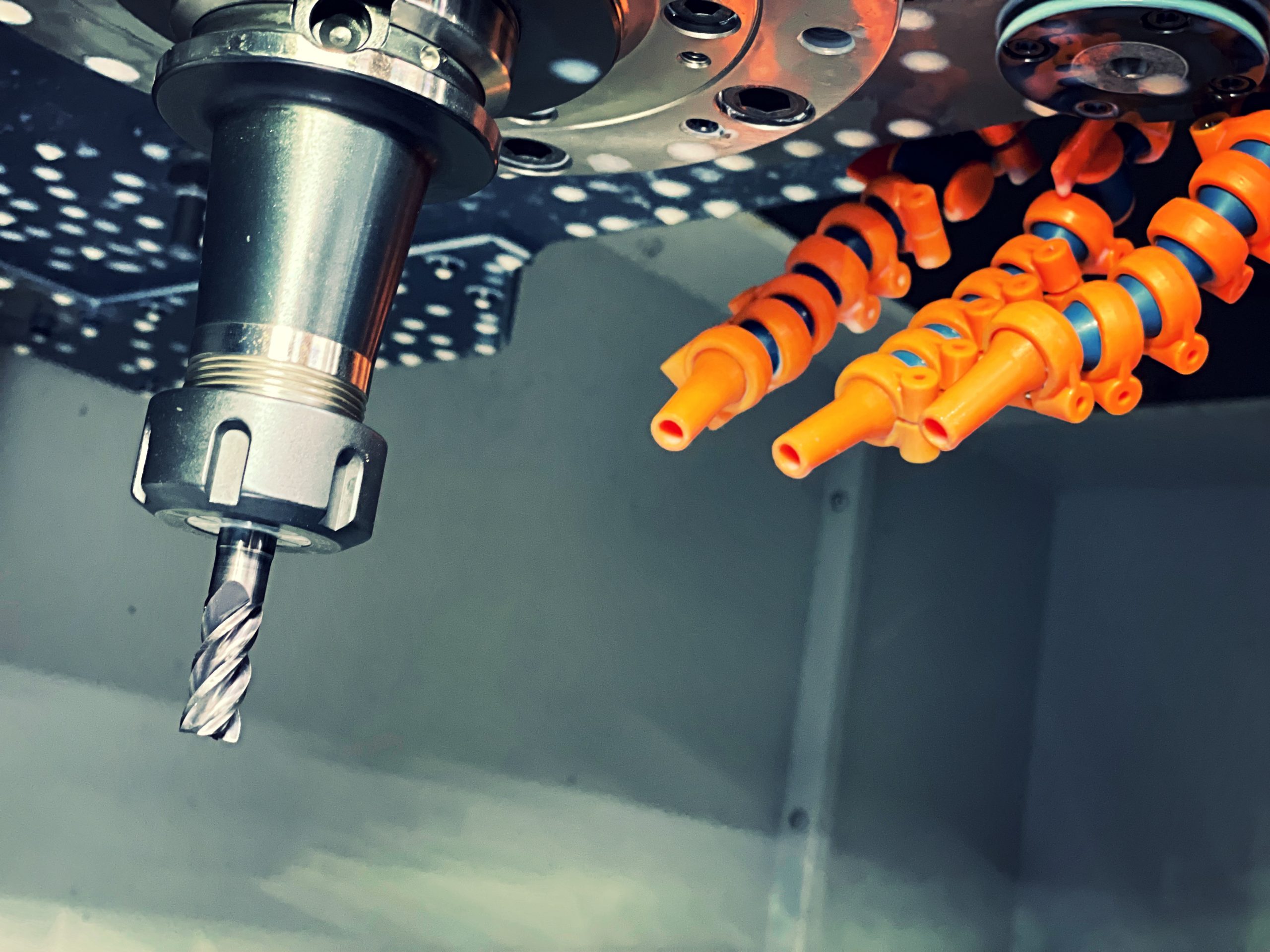

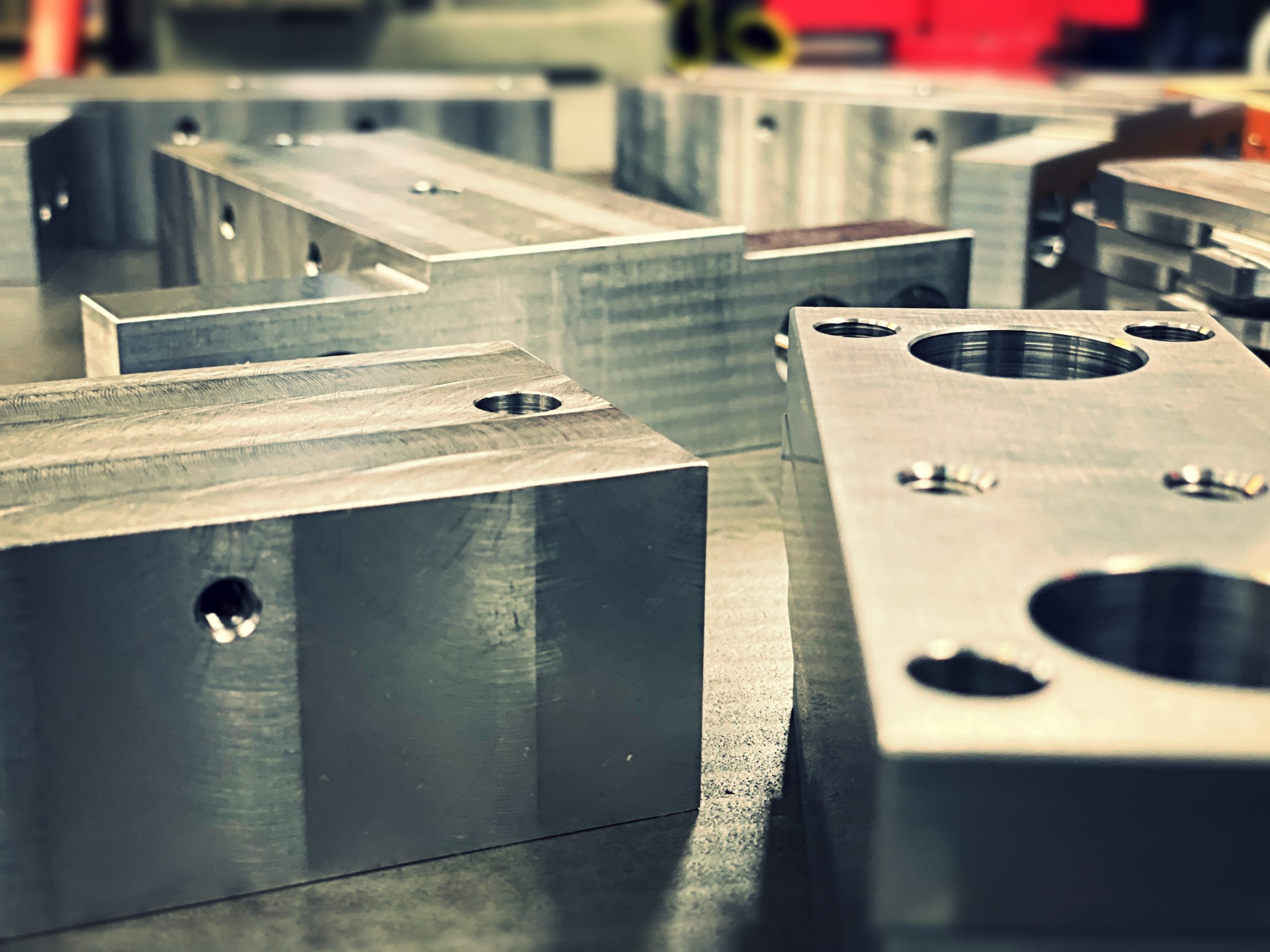

With the setup in place, the CNC turning machine executes the programmed instructions with precision. It rotates the workpiece while the cutting tools deftly remove material from the outer surface, crafting the desired shape, dimensions, and features, including holes, threads, and grooves, among others.

This process is highly versatile, accommodating a wide spectrum of customisations, allowing clients to fashion parts with specific shapes, sizes, and features perfectly tailored to their unique needs.

Should you have any questions or seek more insights into the CNC turning process and how it can address a diverse range of requirements, please don’t hesitate to reach out to us. We’re here to help!

Why Choose Us For CNC Turning In The UK?

Our CNC turning service offers a multitude of advantages to our clients, including:

- Precision: Our machines are meticulously engineered to adhere to stringent tolerances, ensuring industry-leading levels of precision. This enables us to craft even the most intricate designs with unwavering accuracy and consistent results.

- Fast Turnaround: Our machines excel at producing fully finished products swiftly, making CNC turning a practical choice for industries with recurrent demands for last-minute or large-scale production runs.

- Flexibility: Our machines exhibit remarkable versatility in handling a wide array of materials, from natural compounds to synthetics. This adaptability empowers us to meet a diverse spectrum of specifications across many industries.

- Consistency: Our commitment to excellence allows us to consistently reproduce designs to an exceptionally high standard, maintaining unwavering quality.

- Minimal Waste: Our CNC turning service excels at manufacturing accurate and consistent products, consequently reducing wastage while delivering quality goods.

Industry-Leading Quality Control

At Sotek Engineering, we take great pride in upholding stringent standards of quality control across all facets of our manufacturing processes.

For us, quality control is more than just a mere ‘box-ticking’ exercise. It constitutes the bedrock of trust that our clients place in our service, and we remain dedicated to nurturing these relationships by consistently delivering high-quality outcomes over time.

To achieve this, we employ ISO 9001:2015 compliant quality management systems in conjunction with regular inspections and diligent employment of statistical process control (SPC). These measures collectively ensure exceptional standards are maintained throughout our operations.

For more details about our commitment to quality control, you can go here.

About Us

In 2017, Sotek Engineering came into being, thanks to the vision of Steve Brown and Oliver Cumbers. Our primary goal is to provide high-quality subcontract machining, design, reverse engineering, and break-fix solutions to businesses not only in the UK, but beyond.

We rely on state-of-the-art technology, rigorous quality control processes, and an unwavering commitment to delivering outstanding customer service. This approach has solidified our position as a trusted CNC turning solutions provider for a wide range of industries.

Our proudest achievement lies in our impeccable track record of delivering products free from defects. We uphold the most exacting standards of quality control in every facet of our business operations.

Located conveniently near the Devon town of Newton Abbot – adjacent to a major road linking us to the UK motorway network – we’re well-equipped to dispatch parts for same-day or next-day delivery as needed.

Our array of CNC services includes:

• CNC Turning

• CNC Milling

• Design

• Reverse Engineering

• Re-Engineering

Our Testimonials

With a collective experience spanning over 15 years in the manufacturing industry, our team has had the privilege of serving several hundreds of clients over this time, and the outcomes we’ve achieved stand as a testament to our capabilities.

Our proficiency in crafting high quality products has earned us the distinction of being a preferred supplier to clients who demand the utmost precision and accuracy.

Our track record is confirmed by our overwhelmingly positive feedback from our satisfied customers. But don’t just take our word for it; why not read our testimonials?

Contact Us If You’re Looking For Top-Quality CNC Turning In The UK!

Let's get started with your next project...