Sotek Engineering

CNC Turning

Looking For Top-Quality CNC Turning Services?

Make Sure You Contact Us!

At Sotek Engineering, we specialise in providing expert CNC turning services for a wide variety of industries, including Aerospace, Defence, Automotive, Motorsport, Medical, Nuclear, and Oil & Gas.

Our commitment is to deliver high-quality subcontract machining, design, reverse engineering, and repair solutions to our valued clients. We take great pride in consistently delivering flawless results and excellent customer service on every project.

We design and manufacture bespoke parts using state-of-the-art technology, ensuring industry-leading results. Our unwavering focus on strict quality control and full compliance with ISO 9001:2015 standards has earned us a trusted reputation as a leading CNC turning provider across the UK and beyond.

What Does CNC Turning Involve?

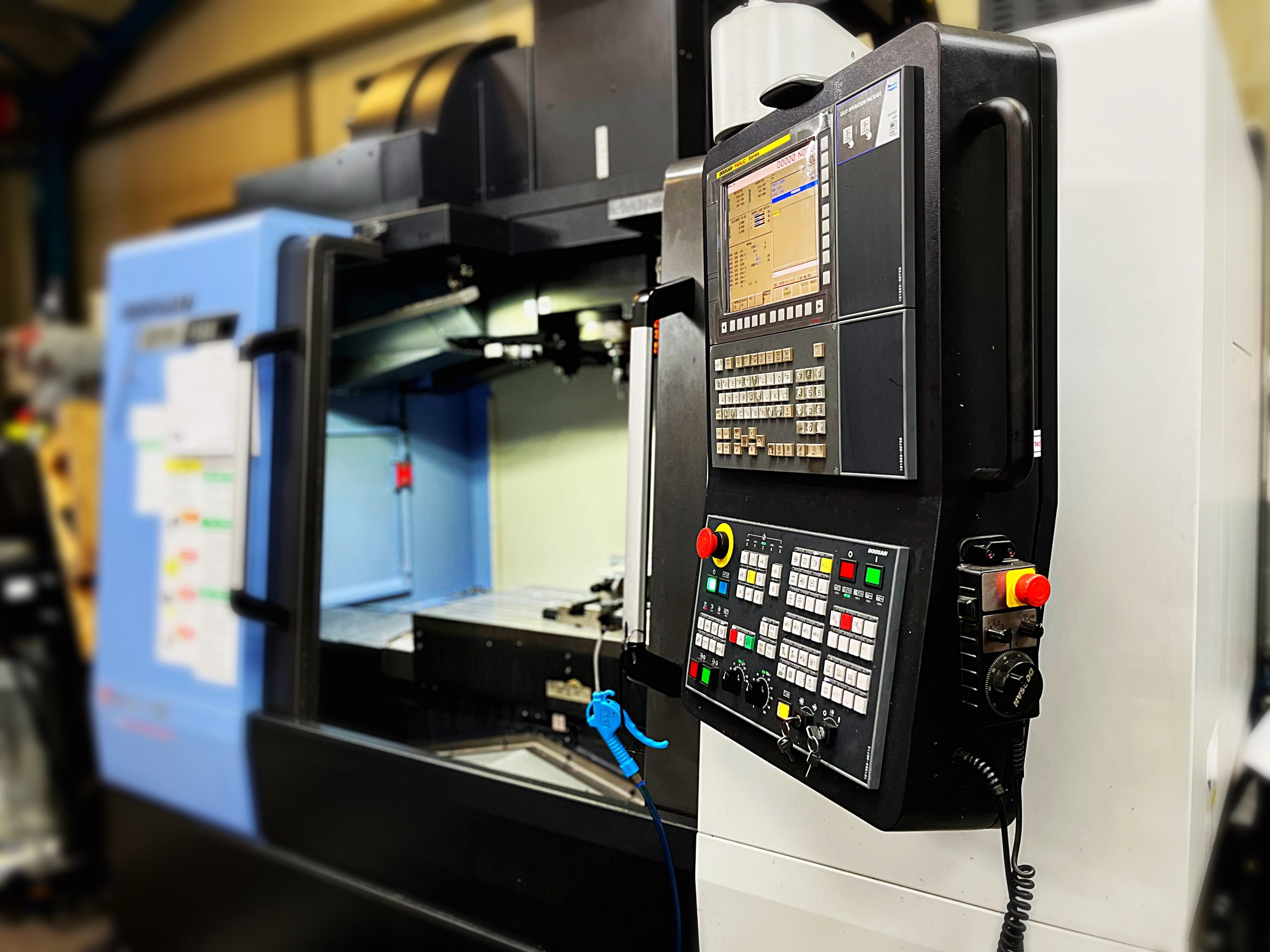

CNC turning delivers precision machining through the use of CNC (Computer Numerical Control) turning machines. The process involves using computer-controlled tools to remove material from a workpiece to create cylindrical or rotational parts with exceptional accuracy.

CNC turning machines can work with a variety of materials, including metals such as steel, aluminium, and brass, as well as plastics and composites. The choice of material depends on the specific requirements of the client’s project.

Thanks to its accuracy, consistency, and high level of customisation, CNC turning is ideal for producing parts for a wide range of industries, such as automotive, aerospace, electronics, and more.

How Our CNC Turning Process Works

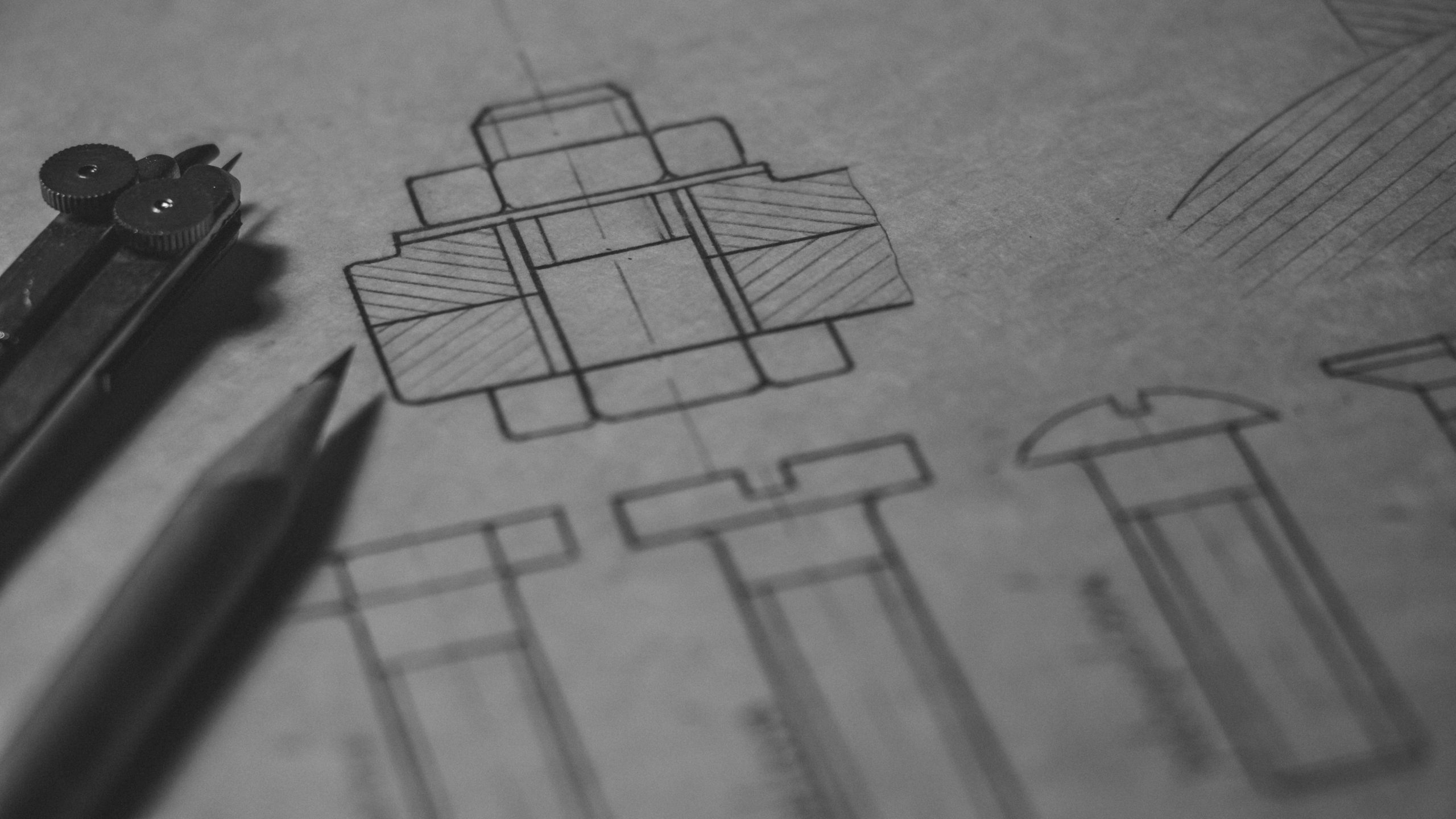

Before machining begins, we work closely with clients to fully understand their design and specifications. Once we have this information, we create a CNC programme that guides the machine in cutting and shaping the chosen materials to meet the desired specifications.

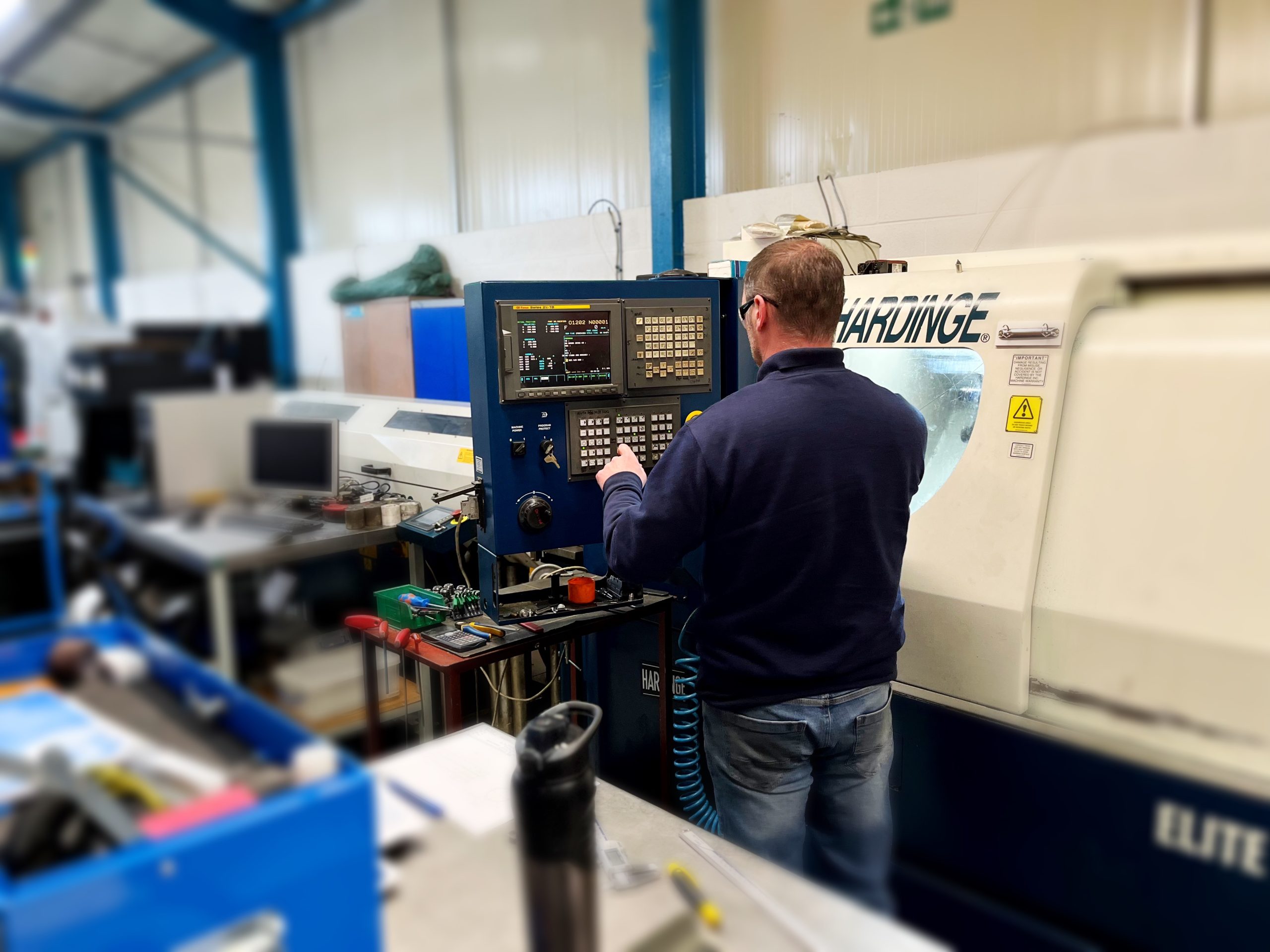

Setting up the CNC turning machine involves securely fastening the workpiece in the chuck and loading the appropriate cutting tools into the tool turret. The machine is then calibrated to ensure precise alignment and positioning.

Once the setup is complete, the CNC turning machine begins its operation according to the programmed instructions. The machine rotates the workpiece while the cutting tools remove material from the outer surface, shaping it into the desired form with features such as holes, threads, and grooves.

This process allows for a high degree of customisation, enabling clients to produce parts with specific shapes, sizes, and features perfectly suited to their needs.

Why Choose Us When You Require CNC Turning Services?

Our CNC turning service offers a wide range of benefits, including:

- Precision – Our machines are built to meet tight tolerances, ensuring industry-leading standards of precision. This allows us to consistently manufacture even the most intricate designs with outstanding results.

- Fast Turnaround – Our machines are capable of producing fully finished products quickly, making CNC turning an ideal option for industries requiring last-minute or large-scale production runs.

- Flexibility – We can work with a wide variety of materials, from organic compounds like wood to synthetic materials. This enables us to meet diverse specifications across many different industries.

- Consistency – We ensure that the same design can be accurately reproduced time after time, maintaining exceptional quality across every production run.

- Minimal Waste – Our ability to produce highly accurate and consistent products results in reduced material waste, while still delivering premium quality at a lower cost.

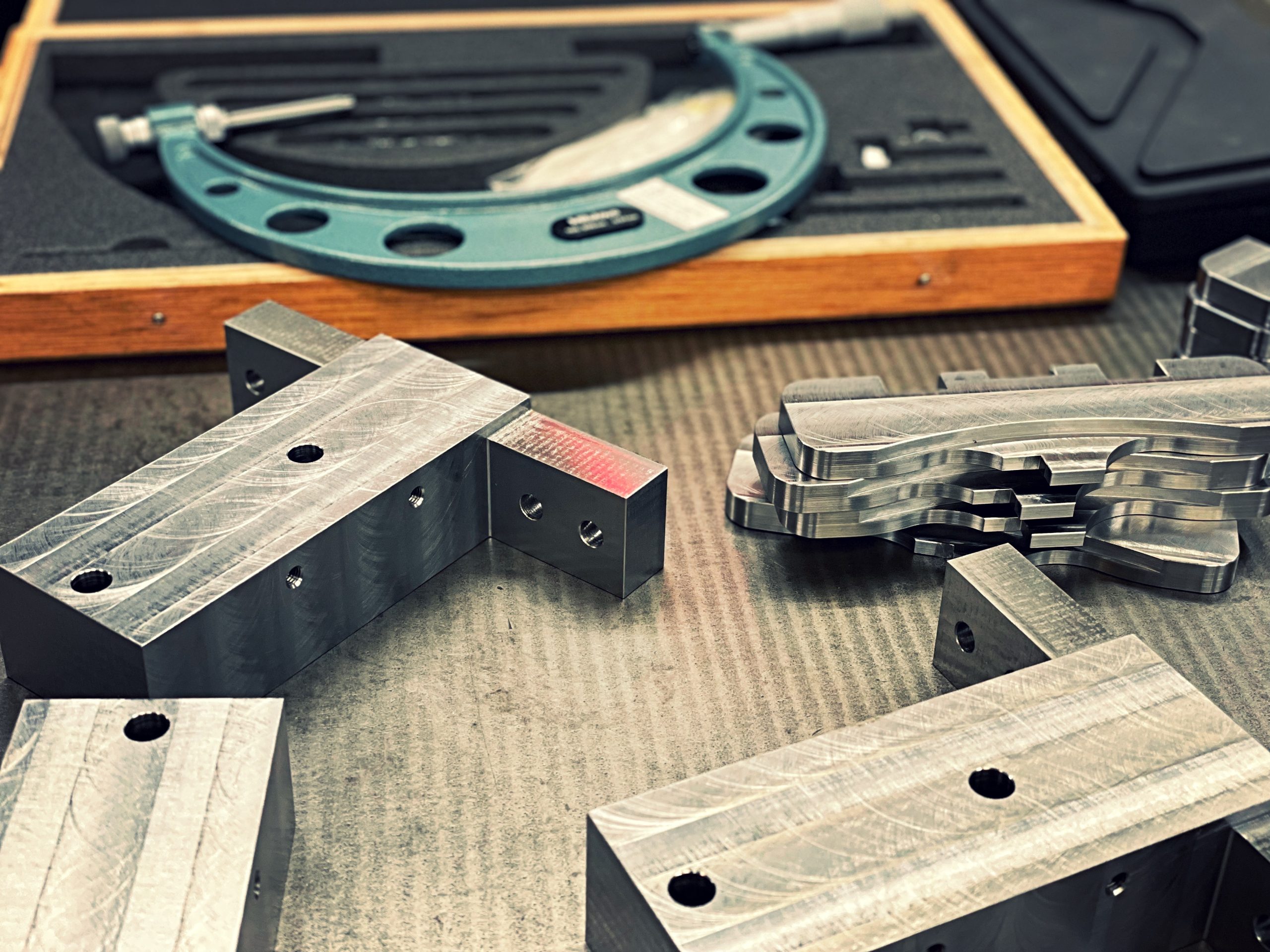

Industry-Leading Quality Control

At Sotek Engineering, we are committed to upholding rigorous quality control standards throughout every step of our manufacturing process.

To us, quality control is not simply a ‘tick-box’ exercise. It forms the foundation of our clients’ trust in us, and we take great care to nurture these relationships by consistently delivering top-quality results.

We utilise ISO 9001:2015 compliant quality management systems, regular inspections, and diligent statistical process control (SPC) to maintain high standards across all our operations.

You can learn more about our commitment to quality control here.

Our History Of CNC Turning

Sotek Engineering was established in 2017 by Steve Brown and Oliver Cumbers with a clear mission: to deliver high-quality subcontract machining, design, reverse engineering, and repair solutions to businesses across the UK and beyond.

Using cutting-edge technology, strict quality control measures, and an unwavering commitment to customer service, we are proud to be a trusted provider of CNC turning solutions for a wide range of industries.

We pride ourselves on our impeccable record of defect-free product delivery and maintain the highest quality standards throughout every aspect of our business.

Located near the Devon town of Newton Abbot, just off the major arterial road connecting to the UK motorway network, we are well-positioned to offer same-day or next-day deliveries as needed.

The comprehensive range of CNC services we provide includes:

- CNC Turning

- CNC Milling

- Design

- Reverse Engineering

- Re-Engineering

Our Testimonials

With over 15 years of experience in the manufacturing industry, our team has served hundreds of clients, and the results speak for themselves!

Our ability to deliver exceptional quality products has made us the preferred supplier for clients who require high precision, including those in the Medical, Aerospace, and Defence sectors.

We are proud of the fantastic feedback we continue to receive from our clients. But don’t just take our word for it—read our testimonials to see how we’ve helped businesses just like yours!

Contact Us If You Need Top-Quality CNC Turning Services!

Let's get started with your next project...