Sotek Engineering

CNC Companies UK

Looking For A Top-Quality CNC Service UK?

Contact Us!

At Sotek Engineering, we specialise in providing CNC services to UK clients in a wide range of industries, such as automotive, motorsport, medical, oil and gas, aerospace, defence, and nuclear sectors.

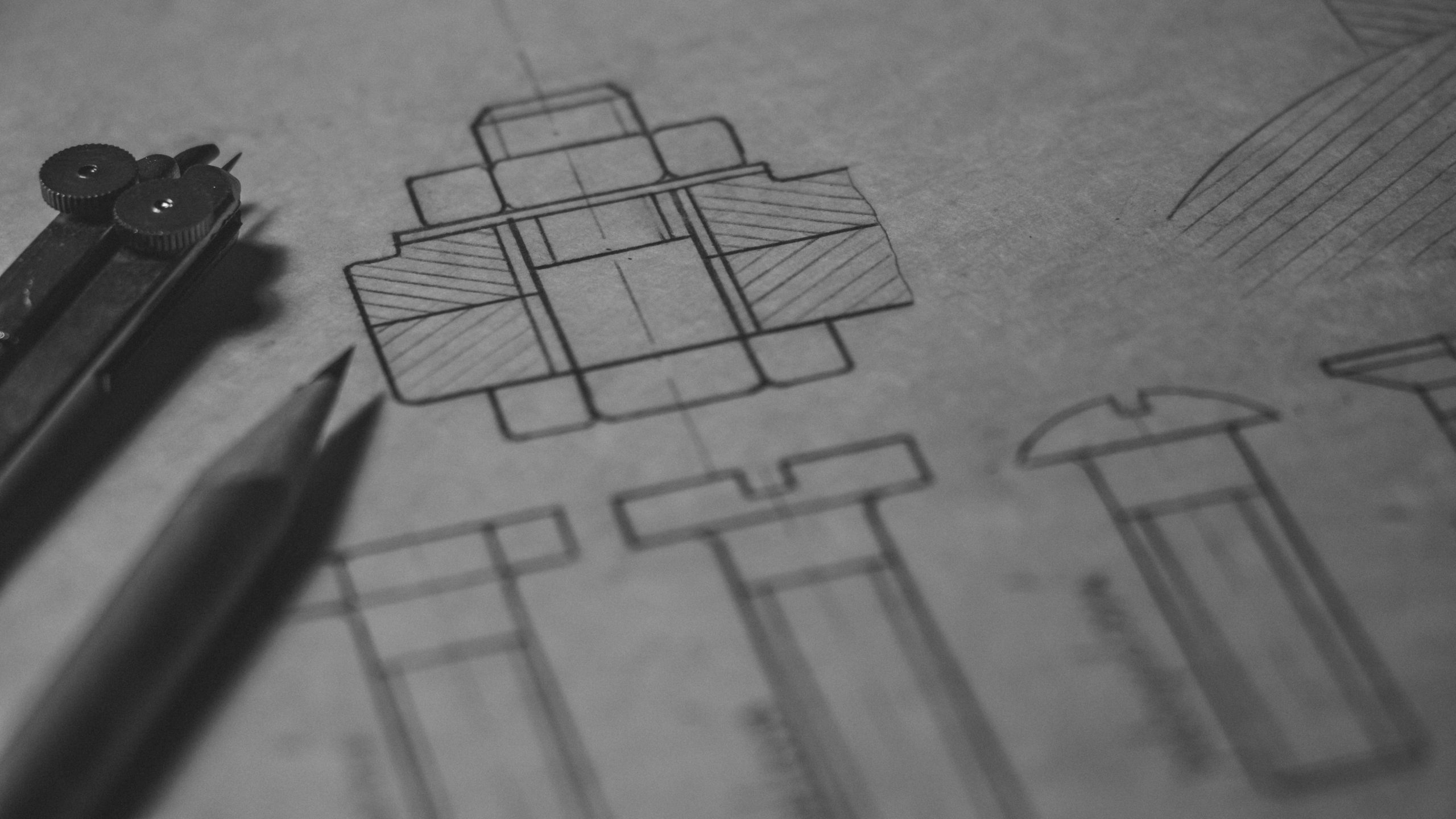

Our mission is to deliver high-quality machining, design, reverse engineering, and break-fix solutions to all our valued clients. Using the latest technological advancements and stringent quality control measures, we design and manufacture quality bespoke parts for our clients’ products, ensuring exceptional results every time!

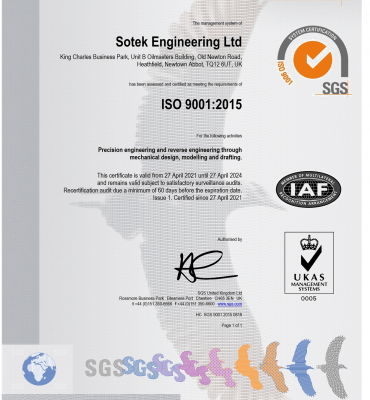

Taking pride in achieving full compliance with ISO 9001:2015 regulations, our hard work and high standards have earned us a reputation as a trusted provider of CNC machining services for many thriving industries.

Consistently delivering superior quality products is our calling card, as shown by our impeccable client satisfaction ratings and many positive reviews.

What Our CNC Service UK Can Offer

CNC Milling

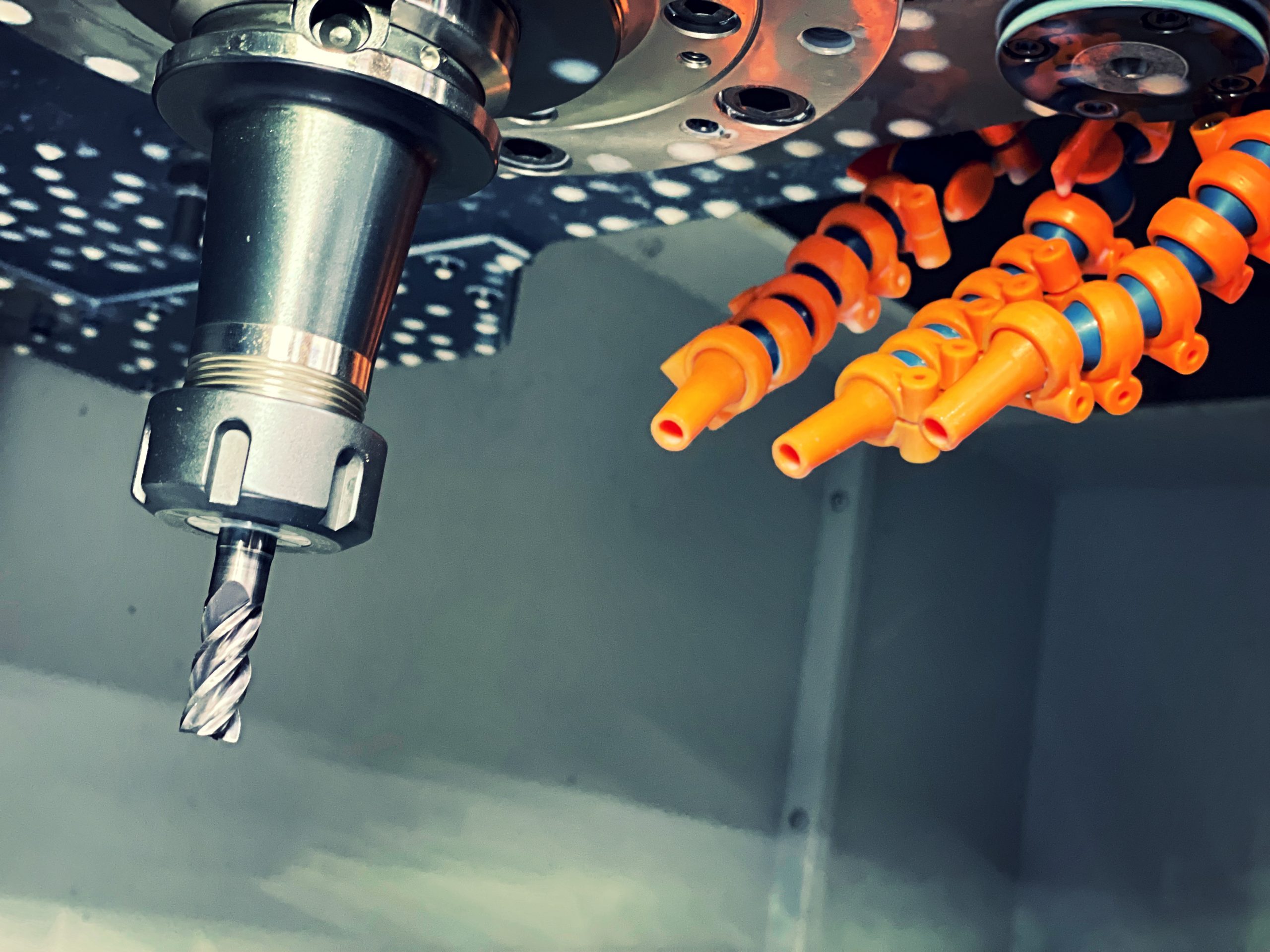

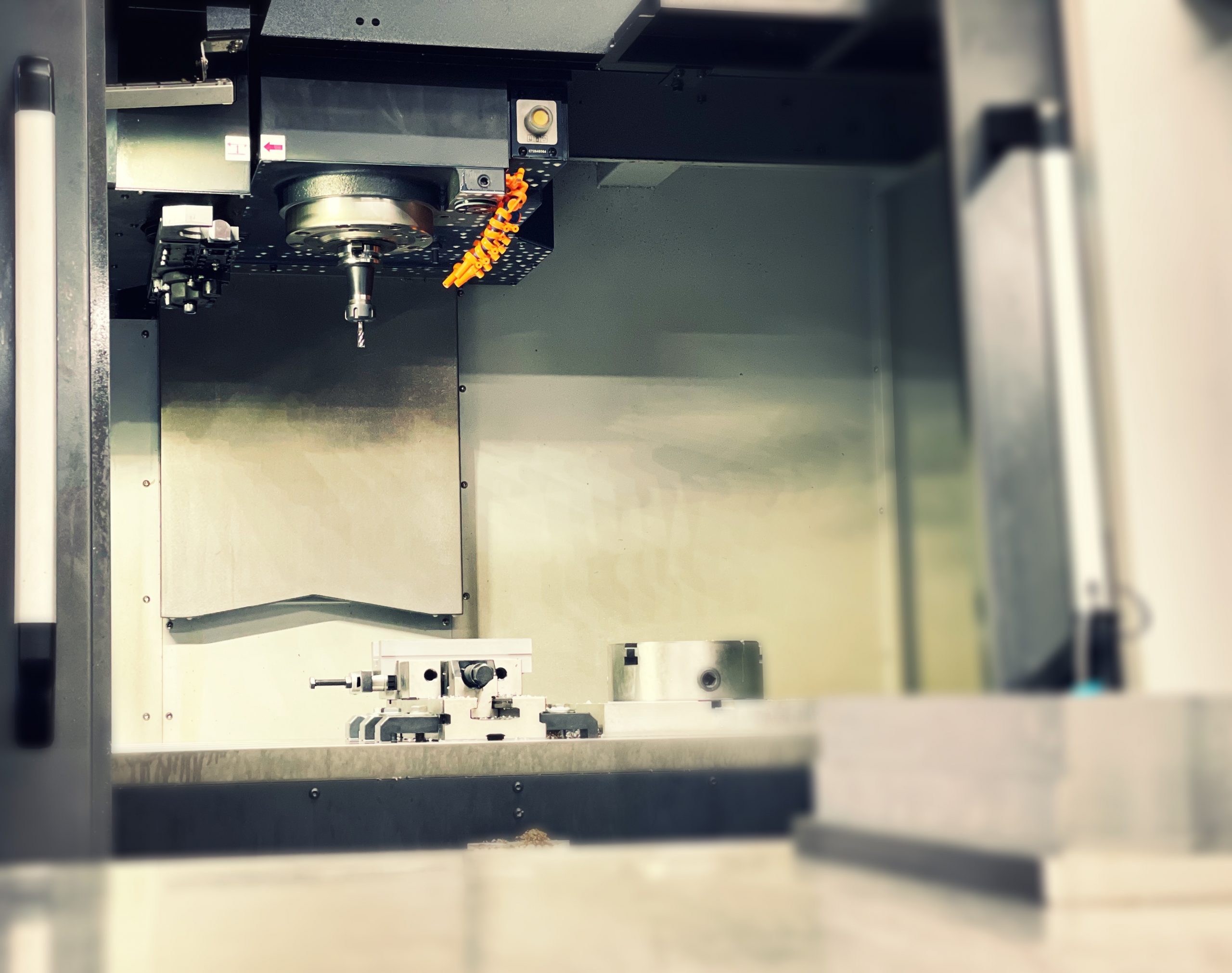

CNC milling is a sophisticated machining technique that employs computer-controlled machinery to craft precise and intricate parts from various materials like metals, plastics, and composites.

Here’s how it works: the workpiece is securely affixed to a worktable, and then a rotating cutting tool is employed by the machine to shape the material according to the design specifications.

This tool moves along multiple axes, including x, y, and z, enabling it to create complex shapes and features like holes, slots, pockets, and contours with remarkable accuracy.

Utilising advanced software and automation, the CNC Milling process achieves exceptional precision in crafting intricate shapes.

Additionally, these machines can be equipped with a diverse array of cutting tools, including end mills, drills, and taps, to accommodate a wide range of milling requirements.

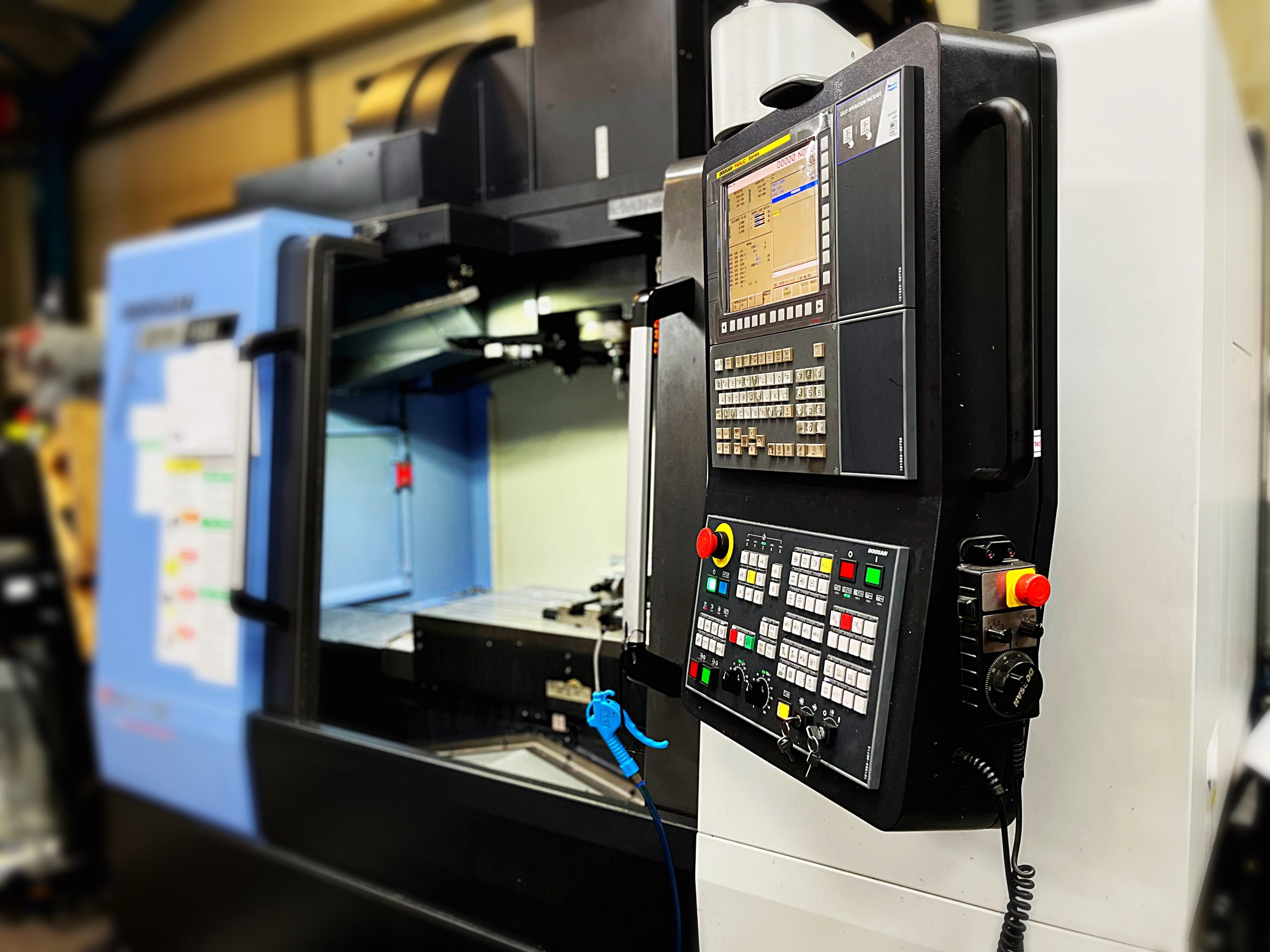

The Types Of CNC Milling Machine

At Sotek Engineering, we have an extensive range of CNC milling machines, including:

- Vertical Milling Machines: These machines feature a vertical spindle that moves up and down the X and Y axes.

- Horizontal Milling Machines: With a horizontal spindle, these machines move side-to-side along the X and Z axes.

- 5-Axis Milling Machines: Capable of crafting intricate parts, these machines move the cutting tool along 5 axes for highly complex designs.

- Gantry Milling Machines: Utilising a fixed bridge spanning the workpiece, these machines can manoeuvre the cutting tool along multiple axes.

The Applications Of CNC Milling

CNC Milling Machines are widely used across many manufacturing sectors for their remarkable precision and capacity to create top-notch products.

These industries include automotive, aerospace, medical, defence, and many more.

The Benefits Of CNC Milling

CNC Milling brings numerous advantages to the manufacturing sector, such as:

- Superior precision

- Reduced defects

- Minimal waste generation

- Enhanced production speed and efficiency

- Swift assembly processes

- Heightened personnel safety

- Lower energy consumption

- Decreased overall production expenses

More Of Our CNC Services

CNC Turning

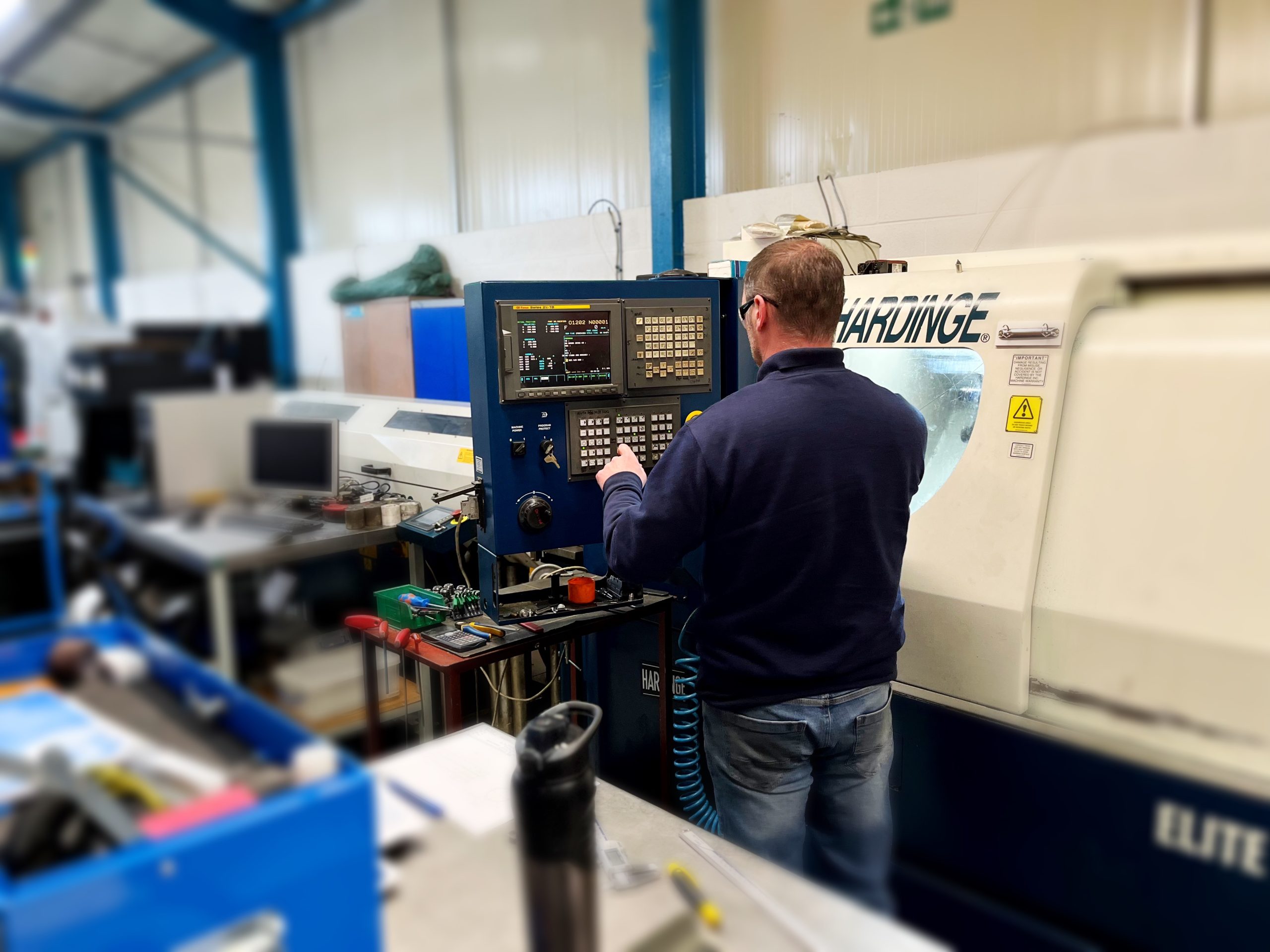

CNC Turning is a machining process that uses a computer-controlled lathe to produce cylindrical or conical parts.

The workpiece rotates while a cutting tool, held in a tool turret or holder, moves along its surface to shape it into the desired form and size.

This lathe machine can perform various functions like facing, drilling, threading, and grooving. Similar to CNC milling, CNC turning is versatile, working with materials like metals, plastics, and composites to generate parts with speed and precision.

The Features Of CNC Turning Machines

Bar Feeder: This handy tool automatically supplies raw materials like metal bars or tubes into the CNC lathe machine, allowing for the creation of long, cylindrical parts. It’s capable of holding multiple materials and feeding them into the machine as needed, cutting down on manual loading time and boosting efficiency.

Driven Tooling: With driven tooling, the CNC turning machine can craft intricate features on the workpiece, such as holes and slots. These features are made possible by rotating cutting tools powered by a motor. This setup enables multiple operations on the workpiece, including drilling, tapping, and milling, all in one go.

The Applications Of CNC Turning

CNC turning machines are used across diverse manufacturing sectors like automotive, aerospace, medical, and defence.

Their capabilities bring several advantages to the manufacturing process, such as improved production efficiency, shorter turnaround times, and decreased costs.

The Benefits Of CNC Turning

- Faster and more efficient production

- Maintains high precision standards

- Generates minimal waste

- Drastically reduces defects

- Enhances personnel safety

- Lowers energy consumption

- Cuts down overall production costs

Why Choose Us If You’re Looking For CNC Companies UK?

We’re thrilled to have served hundreds of happy clients, and the number keeps growing!

With 15 years of experience in the industry, we’ve honed our craft to deliver top-notch products to a wide range of clients. Our knack for creating flawlessly finished products has earned us the trust of many companies with highly demanding standards, particularly in the Medical, Aerospace, and Defence sectors.

Thanks to our expertise and commitment, we’ve consistently received glowing feedback from our valued customers. Check out our testimonials to see what they have to say!

Our Quality Control

At Sotek Engineering, we’re firm believers that maintaining top-notch quality control standards is key to delivering exceptional results. We’re dedicated to integrating quality control principles into every aspect of our work, a commitment that has earned us the trust of our valued customers.

We understand that our client relationships are built on a bedrock of trust. By making quality control a priority, we’re able to consistently deliver on our promises and provide high-quality results every time.

To ensure quality control remains at the forefront of our operations, we adhere to ISO 9001:2015 compliant quality management systems. We also conduct regular inspections and implement diligent statistical process control (SPC). If you’d like to learn more about our unwavering commitment to quality control, click here.

About Our CNC Service UK

Sotek Engineering was founded in 2017 by Steve Brown and Oliver Cumbers with a straightforward yet powerful goal: to provide top-notch machining, design, reverse engineering, and break-fix solutions to businesses throughout the UK.

We take pride in being a reliable provider of CNC turning services to various industries. Utilising cutting-edge technology, stringent quality control measures, and an unwavering dedication to exceptional customer service, we’ve built a stellar reputation for delivering flawless products.

Conveniently located in Newton Abbot, just off the main arterial road connecting to the UK motorway network, we can facilitate same-day or next-day deliveries as needed.

At Sotek Engineering, we offer a comprehensive suite of CNC services, including:

- CNC Routing

- CNC Milling

- Design

- Reverse Engineering

- Re-Engineering

Contact Us If You’re Looking For Top-Quality CNC Companies UK!

Let's get started with your next project...