Sotek Engineering

CNC Precision Machining

Looking For A Top-Quality CNC Precision Machining Company?

Contact Us!

At Sotek Engineering, we take pride in providing superior-quality CNC precision machining, design, reverse engineering, and repair solutions.

Our services provide advanced CNC (Computer Numerical Control) machining that’s specifically designed to cater to a wide range of industries. We’re dedicated to delivering exceptional quality for every client, supported by our ISO 9001:2015 certified quality management system. Through regular inspections and statistical process control (SPC), we make sure every project meets our high standards.

This commitment to quality has helped us build a strong reputation as a trusted supplier of CNC machining services in key sectors like Automotive, Motorsport, Medical, Oil and Gas, Aerospace and Defence, and Nuclear.

Understanding CNC Machining

CNC machining is a manufacturing process that uses computer-controlled machines to cut, carve, and shape materials to precisely meet design specifications.

This process offers unparalleled accuracy and repeatability, making it ideal for producing intricate parts across various industries, including aerospace, automotive, medical, and electronics.

The Process Of CNC Precision Machining

CNC machining involves several steps:

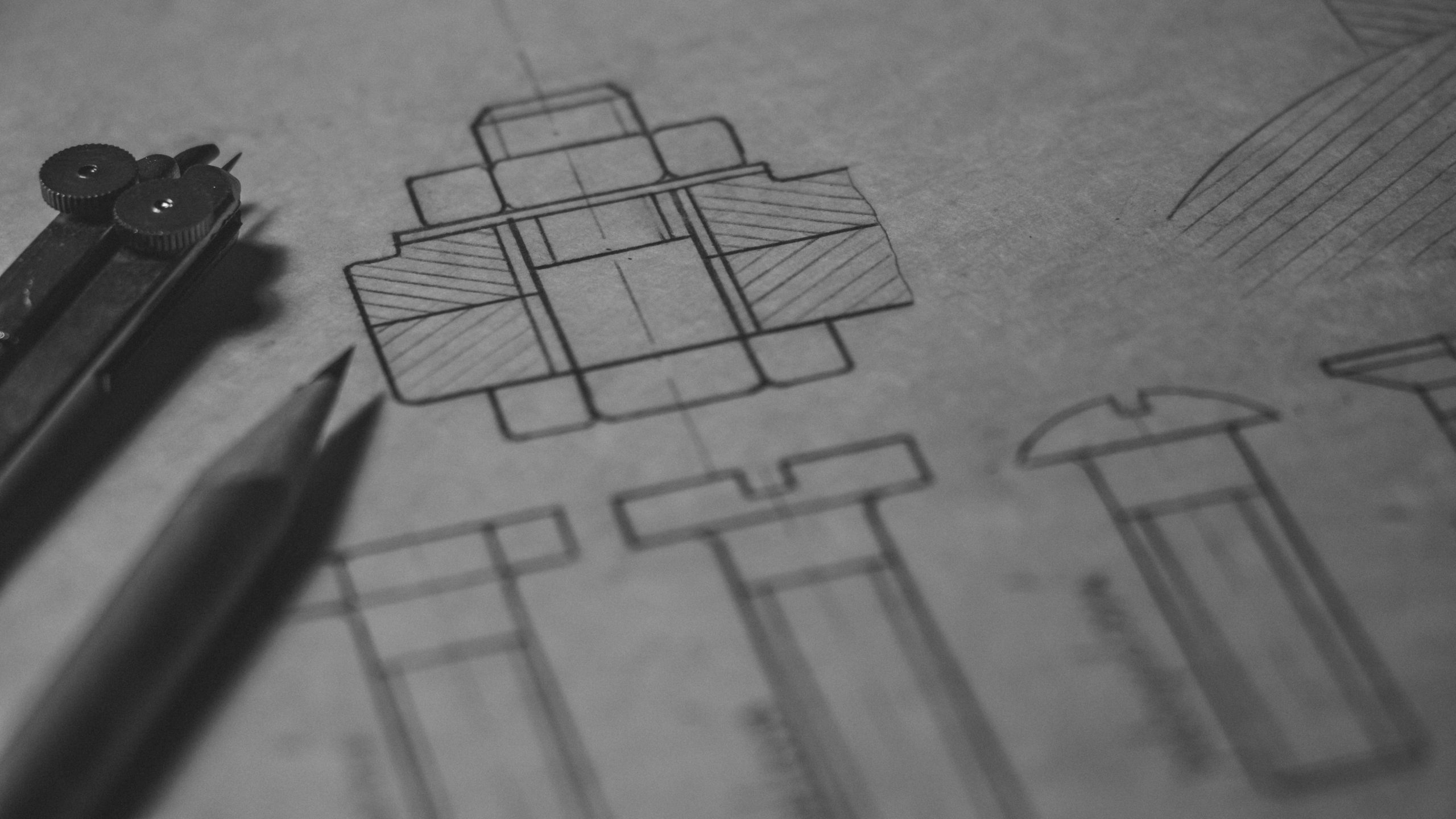

- Design: Engineers and designers create a 3D CAD (Computer-Aided Design) model of the component. This model serves as the blueprint for the machining process.

- Programming: The CAD model is converted into a CNC program, typically written in G-code, which instructs the CNC machine on how to execute the machining process.

- Setup: The machine is set up with the appropriate tools and materials. This includes securing the workpiece and calibrating the machine for precision.

- Machining: The CNC machine follows the programmed instructions to cut and shape the material. This process can involve various techniques, including milling, turning, drilling, and grinding.

- Quality Control: After machining, the components undergo rigorous quality checks to ensure they meet the specified tolerances and standards.

Why Choose Sotek Engineering To Be Your CNC Precision Machining Company?

At Sotek Engineering, we are proud to excel in providing precision CNC machining services. Some of the benefits we offer to our clients include:

1. Advanced Technology And Equipment

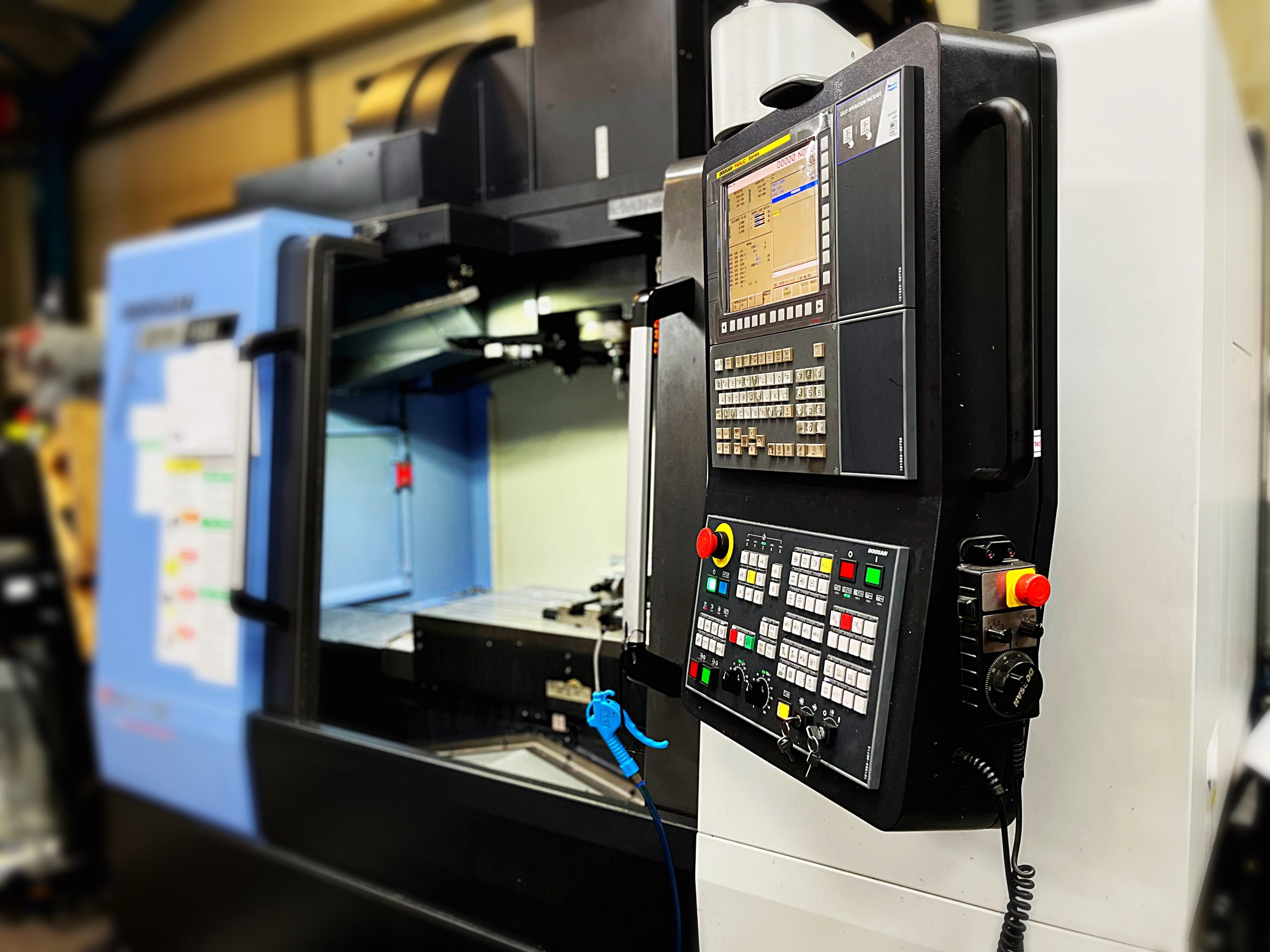

At Sotek Engineering, we use advanced CNC machinery equipped with state-of-the-art technology to deliver high-precision components. These include multi-axis CNC machines capable of executing complex machining tasks that traditional methods may struggle with.

This allows us to work with a wide range of materials, including metals, plastics, and composites, ensuring versatility and adaptability to various project requirements.

2. Skilled Workforce

Our team of skilled designers and engineers is the backbone of our operations at Sotek Engineering. Our experienced team is not only trained in CNC programming and machining, but knowledgeable in industry standards and regulations too.

Their expertise enables them to interpret complex designs and convert them into market-ready products by adhering to stringent quality controls.

3. Custom Solutions

Every project is unique, and at Sotek Engineering, we understand the importance of tailored solutions. We collaborate closely with our clients to understand their specific needs, whether it involves prototyping a new part or proceeding to mass production.

This customer-centred approach ensures that our clients receive accurate, precision-designed products, on time and within budget.

4. Quality Assurance

We place quality front and centre in all our operations. Our process follows a rigorous quality management system that adheres to international standards. Every component produced undergoes strict inspection and testing to ensure accuracy and reliability.

By investing in advanced measuring equipment and quality control processes, we ensure that every part meets or exceeds client specifications.

5. Rapid Prototyping And Production

Completing processes quickly and efficiently is essential to keeping manufacturing and labour costs low for our clients. Our precision CNC machining services include rapid prototyping, allowing clients to quickly develop and test designs before committing to full-scale production.

This not only accelerates time-to-market but also helps identify potential issues early in the design process, reducing costs and improving overall efficiency.

6. Commitment To Sustainability

At Sotek Engineering, we are also dedicated to sustainability in our manufacturing processes. By optimising machining parameters and minimising waste, we can reduce our environmental impact while maintaining quality standards.

This commitment to sustainability is increasingly important to clients who prioritise environmentally responsible practices.

The Industries We Serve

Our precision CNC machining services cater to a wide range of industries, including:

Aerospace

In the aerospace sector, precision is non-negotiable for ensuring safety and performance. At Sotek Engineering, our precision machining capabilities allow for the production of complex components that meet strict safety and performance standards.

From turbine blades to structural components, we pay close attention to detail to ensure that every part is manufactured to exact specifications.

Automotive

At Sotek Engineering, we provide precision machining services for various automotive components, including engine parts, transmission components, and chassis elements.

Our ability to deliver high-quality parts quickly and efficiently makes us a trusted partner for automotive manufacturers.

Medical

Precision machining is critical for the production of surgical instruments, implants, and diagnostic equipment.

We are equipped to handle the stringent regulations and quality standards required in the medical industry, ensuring that every product is safe and reliable while using ergonomic principles to promote high standards of care and comfort for patients.

Electronics

The electronics industry often demands intricate and delicate components that require exceptional precision.

Our extremely accurate CNC machining capabilities allow for the production of housings, connectors, and circuit boards capable of meeting even the highest precision standards.

Why Choose Us For CNC Precision Machining?

At Sotek Engineering, we are proud to be an industry leader in precision CNC machining services, combining advanced technology, skilled personnel, and a commitment to quality to meet the evolving needs of various industries. From rapid prototyping or mass production of complex components, our tailored solutions ensure you receive only the highest quality services, resulting in superior-quality products.

With a focus on innovation, quality assurance, and sustainability, we are your partner for high-quality manufacturing services. Whether you’re in need of prototyping, custom manufacturing, or quality assurance, we are perfectly equipped to bring your concepts to market!

About Us

Sotek Engineering was founded in 2017 by Steve Brown and Oliver Cumbers with a simple but ambitious goal: to provide top-notch machining, design, reverse engineering, and break-fix solutions to businesses across the UK and beyond.

We’re proud to be a reliable provider of CNC turning services across a variety of industries. By using cutting-edge technology, maintaining high standards of quality, and focusing on excellent customer service, we’ve built a strong reputation for delivering exceptional products.

Our convenient location in Newton Abbot, just off the main road connecting to the UK motorway network, means we can offer same-day or next-day delivery when needed.

At Sotek Engineering, we offer a full range of CNC services, including:

- CNC Routing

- CNC Milling

- Design

- Reverse Engineering

- Re-Engineering

Contact Us If You Need A CNC Precision Machining Company!

Let's get started with your next project...