Sotek Engineering

CNC Plastic Milling

Looking For A Top-Quality CNC Plastic Milling Service?

Contact Us!

At Sotek Engineering, we provide high-quality CNC plastic milling services designed to meet the strict requirements of key industries such as automotive, aerospace, medical, and more.

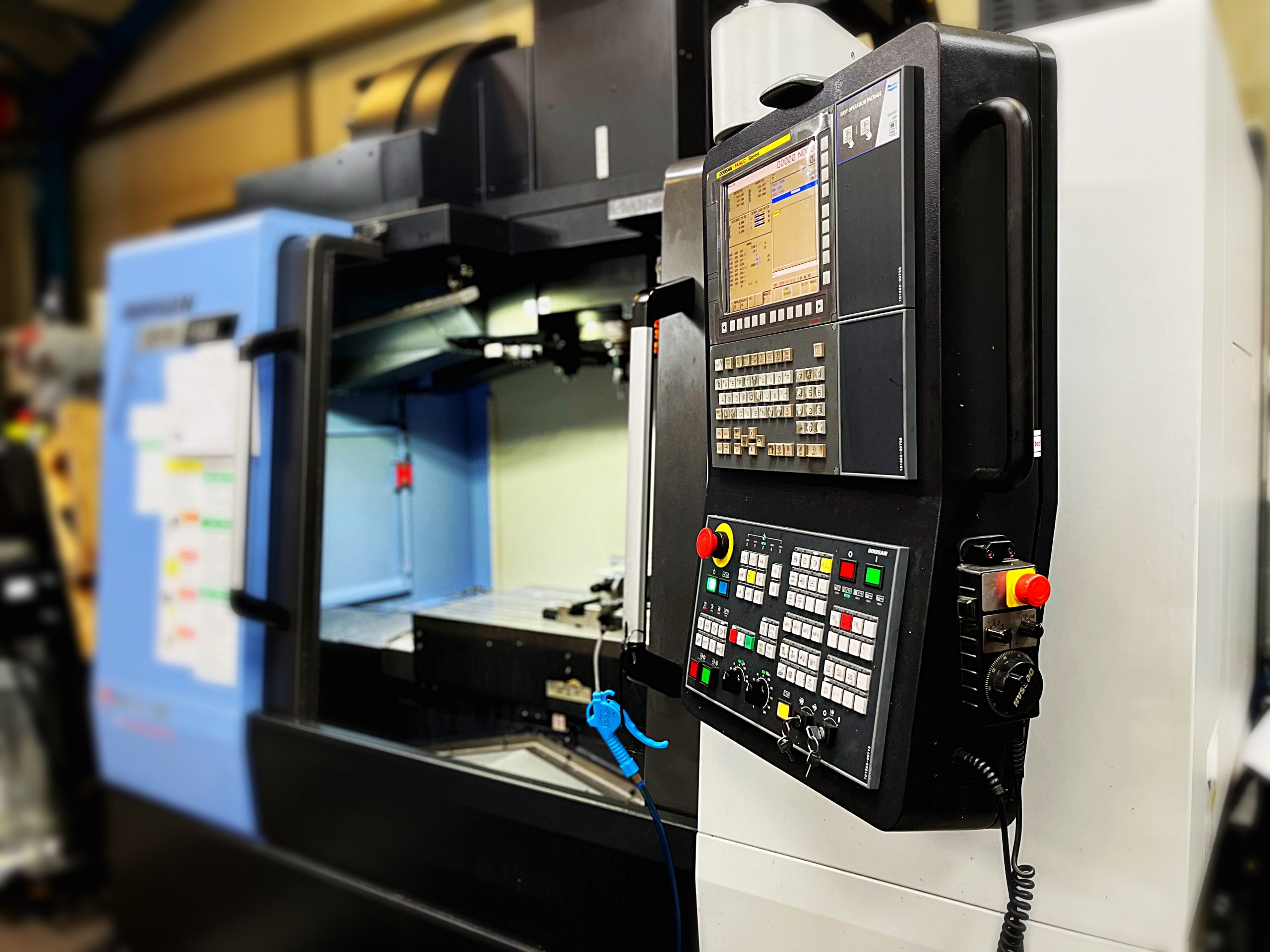

Using advanced CNC milling technology, we ensure industry-leading precision, consistency, and flexibility in the production of complex plastic components.

What Is CNC Plastic Milling?

CNC (Computer Numerical Control) plastic milling is a subtractive manufacturing process that uses computer-controlled tools to remove material from a solid block of plastic, creating intricate and precise components.

CNC milling uses pre-programmed software to cut along multiple axes (X, Y, Z), enabling the production of highly detailed and geometrically complex parts.

The CNC Plastic Milling Process

- Programming: A digital model of the desired part is translated into machine instructions using CAD/CAM software.

- Material Preparation: A plastic workpiece is securely fastened to the machine’s worktable.

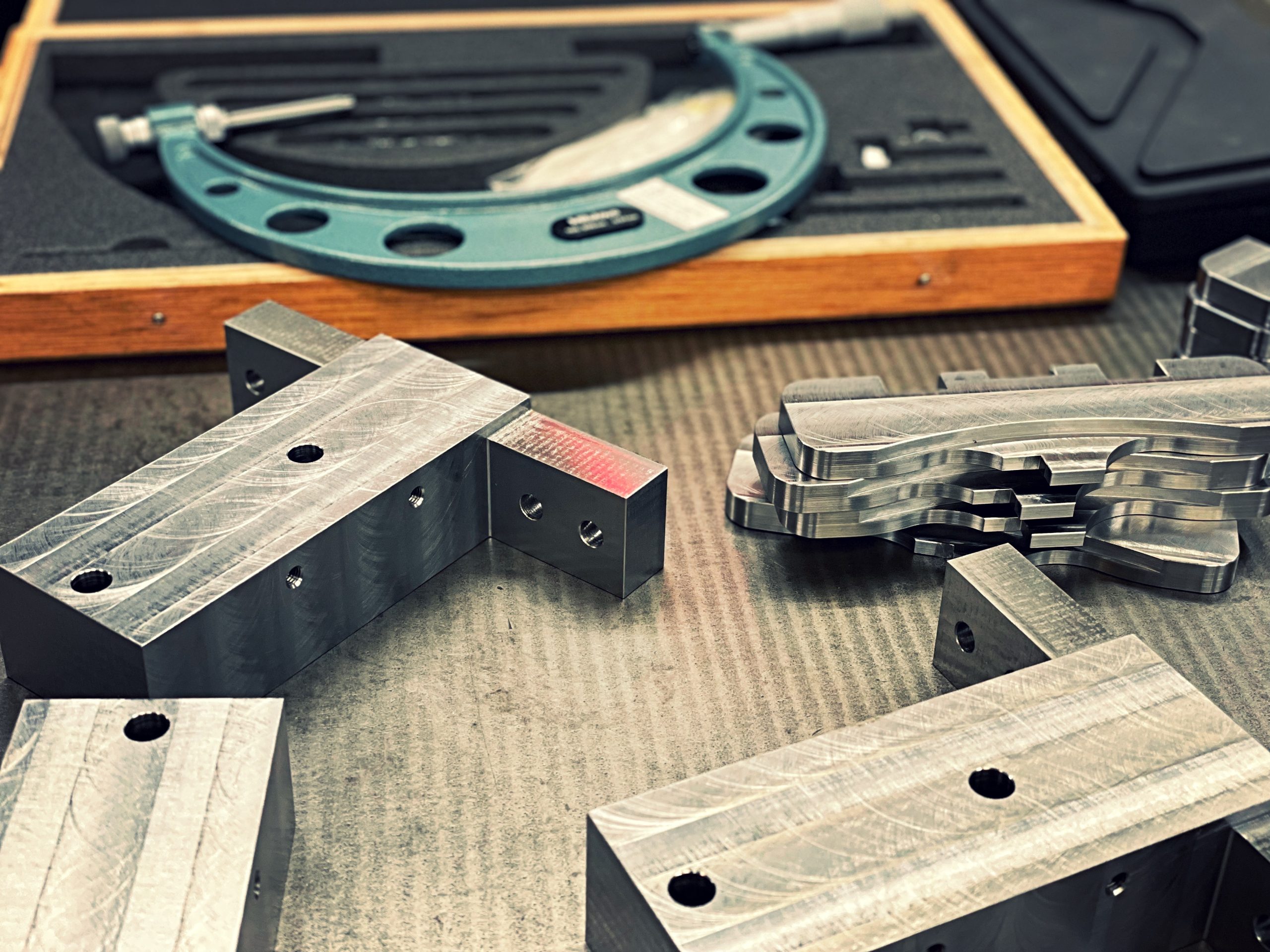

- Precision Cutting: Rotating cutting tools remove material from the workpiece to achieve the specified design.

- Multi-Axis Machining: Our advanced CNC machines operate along multiple axes, allowing for the creation of features such as slots, holes, contours, and intricate geometries.

The Materials Used In CNC Plastic Milling

Our CNC milling machines are compatible with a wide range of plastic polymers, each offering unique properties to suit specific applications.

The following are just some of the materials we work with and the qualities they offer:

- Delrin (POM): Ideal for precision components requiring high stiffness and dimensional stability.

- Nylon: Offers excellent wear resistance, making it suitable for mechanical parts.

- Acrylic: Used for optical applications due to its clarity.

- Teflon (PTFE): Provides high chemical resistance and low friction.

- PEEK: Known for its strength and resistance to extreme conditions.

- UHMW Polyethylene: Common in industrial applications for its durability and impact resistance.

The Advantages Of Our CNC Plastic Milling Services

Our CNC plastic milling services offer numerous benefits to our clients, making us a trusted partner for industries that require precision, efficiency, and versatility.

Exceptional Precision

CNC milling offers unparalleled accuracy, enabling the creation of parts with tight tolerances. This is crucial for industries like aerospace and medical devices, where even minor inaccuracies can compromise functionality.

Our advanced machinery ensures every component meets exact specifications.

Complex Design Capabilities

With multi-axis capabilities, our CNC milling machines can produce intricate parts that would be challenging or even impossible using traditional methods.

From internal channels to complex contours, our services prioritise precision and design flexibility.

Consistency And Repeatability

One of the key advantages of CNC milling is its ability to produce identical parts in large production runs.

At Sotek Engineering, we ensure consistent quality standards across all our operations.

Reduced Waste

CNC milling minimises material waste by precisely cutting to specifications and reducing defects. This results in cost savings for clients while promoting sustainable practices.

Wide Material Compatibility

Our CNC machines are highly versatile, allowing for the use of various plastics. This ensures that the right material is chosen for every application, meaning we can meet the diverse needs of a wide range of industries, from medical to automotive.

Quick Turnaround Times

Using our automated processes, our team can complete projects faster and more efficiently than traditional machining methods. We also offer rapid prototyping, allowing our clients to test and refine designs with minimal delay.

The Applications Of CNC Plastic Milling

At Sotek Engineering, our CNC plastic milling services cater to a wide range of industries. Here are some examples of what we manufacture for several key sectors:

Automotive And Aerospace

- Custom plastic parts for vehicles and aircraft.

- Lightweight components that reduce fuel consumption while maintaining strength.

- Engine housing, fittings, and ducting.

Medical Devices

- Surgical instruments, diagnostic equipment, and prosthetics.

- Biocompatible materials that meet stringent health standards.

- Custom components for precision medical applications.

Electronics

- Insulation and non-conductive parts for electrical systems.

- Housing for sensitive electronic components.

- Components for consumer and industrial electronics.

Food And Drink

- Plastic components for machinery used in food processing.

- Parts designed to meet strict hygiene and safety regulations.

Our Commitment To Quality

At the heart of our operations is an unwavering commitment to quality. We adhere strictly to ISO 9001:2015 standards, ensuring that every component produced meets rigorous quality requirements.

Some of our key quality measures include:

Statistical Process Control (SPC): Monitoring production processes to ensure consistency.

Regular Inspections: Ensuring that all parts adhere to client specifications and industry standards.

Client-Centric Approach: Collaborating closely with our clients to ensure that each product we manufacture meets their exact specifications.

This dedication to quality has earned us a reputation as a trusted provider of CNC plastic milling services.

Why Choose Sotek Engineering?

At Sotek Engineering, we combine our professional expertise with the latest technological advancements and a customer-focused approach to deliver exceptional results.

Some reasons why our clients choose us for CNC plastic milling include:

Expertise Across Diverse Sectors: Our experience in sectors such as automotive, aerospace, and medical has given us a deep understanding of the unique requirements of each field.

State-Of-The-Art Equipment: Multi-axis CNC machines enable precise and efficient production of complex parts.

A Highly Reputable Supplier: At Sotek Engineering, we are proud to have consistently delivered exceptional services and high-quality components over time, earning us the trust of our clients.

About Us

At Sotek Engineering, our CNC plastic milling services prioritise precision, versatility, and reliability across each stage of the manufacturing process. From prototyping to large-scale production, we provide tailored solutions for complex manufacturing needs.

Our advanced technology, strict quality controls, and commitment to client satisfaction have made us a trusted partner for a wide range of industries.

You can learn more about CNC milling here, or read our client testimonials on this page!

Let's get started with your next project...