Sotek Engineering

CNC Plastic Machining

Looking For A Top-Quality Plastic CNC Machining Service?

Contact Us!

At Sotek Engineering, we offer high-quality plastic CNC machining services to clients across various industries, including automotive and motorsport, medical, oil and gas, aerospace and defence, nuclear, and more.

We pride ourselves on delivering high-quality subcontract machining, design, reverse engineering, and break-fix solutions. By utilising the latest CNC machining technology alongside rigorous quality controls, we consistently ensure outstanding results for our wide range of clients!

We’re also proud to be fully compliant with ISO 9001:2015 standards, which solidifies our reputation as a trusted and highly-rated provider of CNC machining services. But don’t just take our word for it—check out some recent client reviews!

About CNC Plastic Machining

What Is Plastic CNC Machining?

Plastic CNC machining is an incredibly versatile manufacturing process that can produce a wide range of plastic products. It operates as a subtractive method, employing techniques like milling and turning to achieve precise results.

In plastic CNC machining, a computer-controlled machine tool is used to craft complex, precision-engineered parts from various plastic polymers. Common plastics suitable for CNC milling include Delrin (POM), nylon, acrylic, Teflon (PTFE), PEEK, and ultra-high molecular weight polyethylene (UHMW).

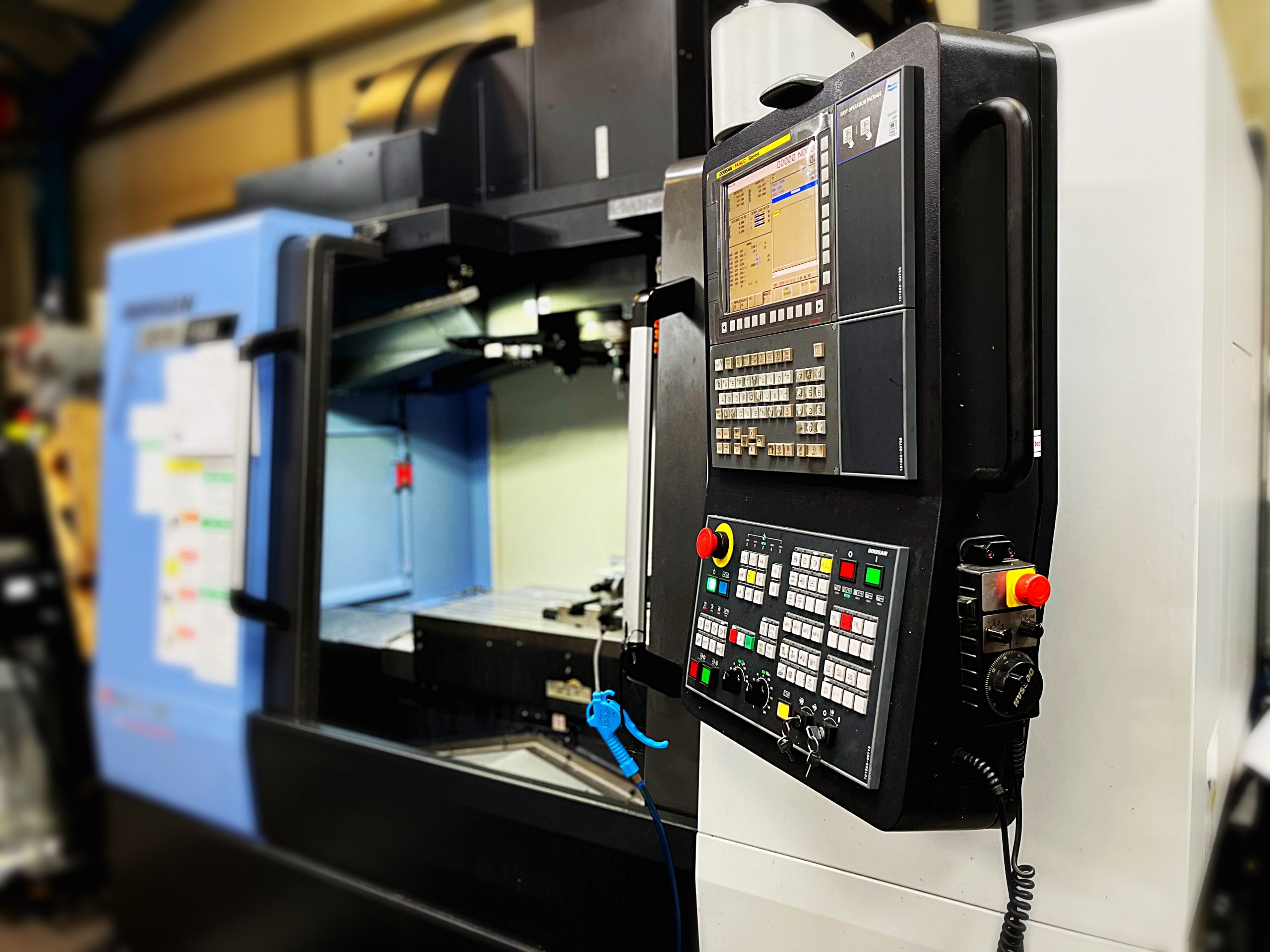

There are two primary types of CNC machining: CNC milling and CNC turning.

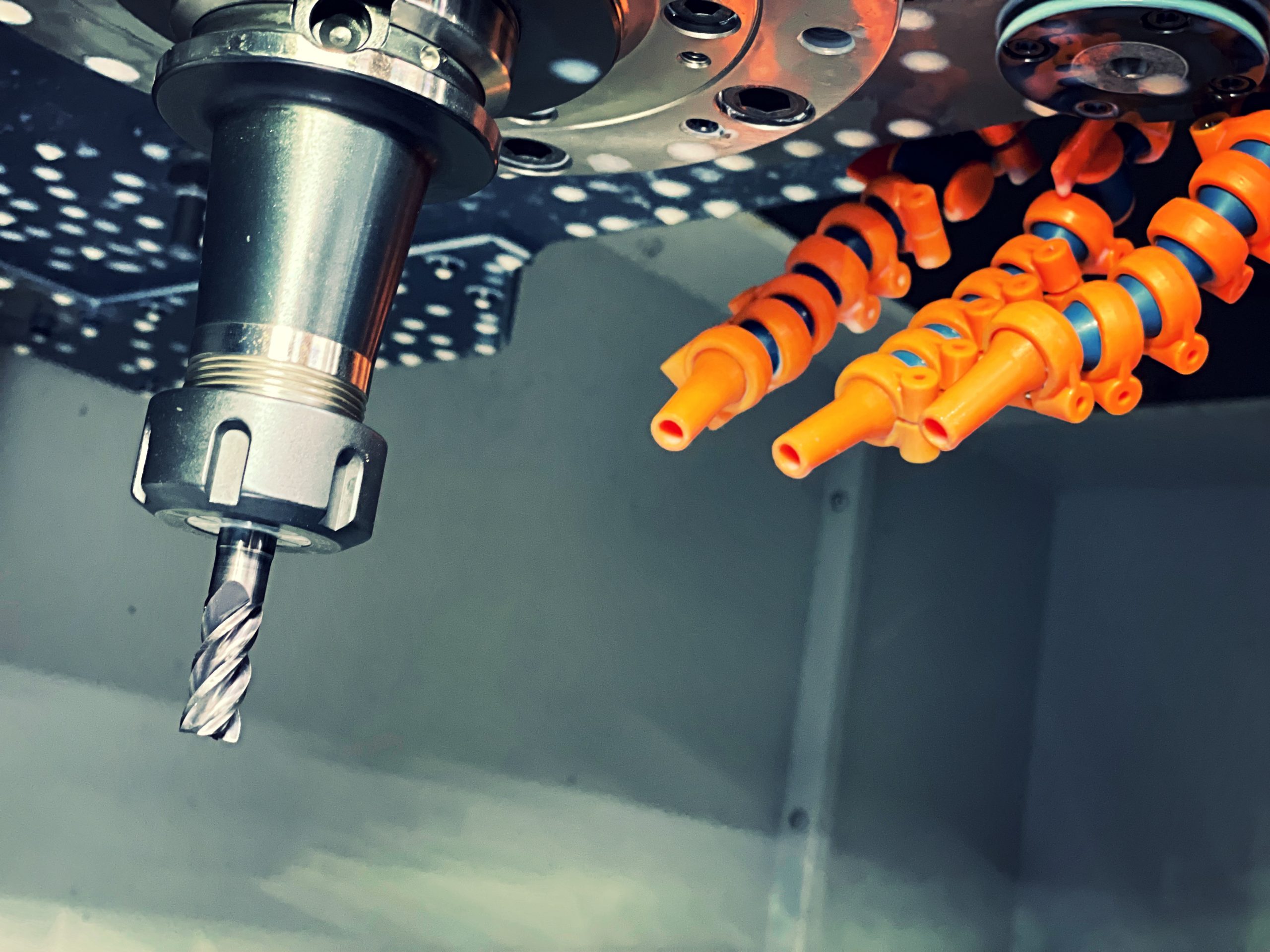

CNC Milling

CNC milling is efficient for mass-producing plastic products with tight tolerances and quick turnaround times.

In this process, the plastic workpiece is secured to a worktable, and a rotating cutting tool removes material according to the specified design. This tool can move along multiple axes to shape the final product precisely.

By programming it to operate on the X, Y, and Z axes, we can create intricate shapes and features such as holes, slots, pockets, and contours, as well as flat or irregular surfaces.

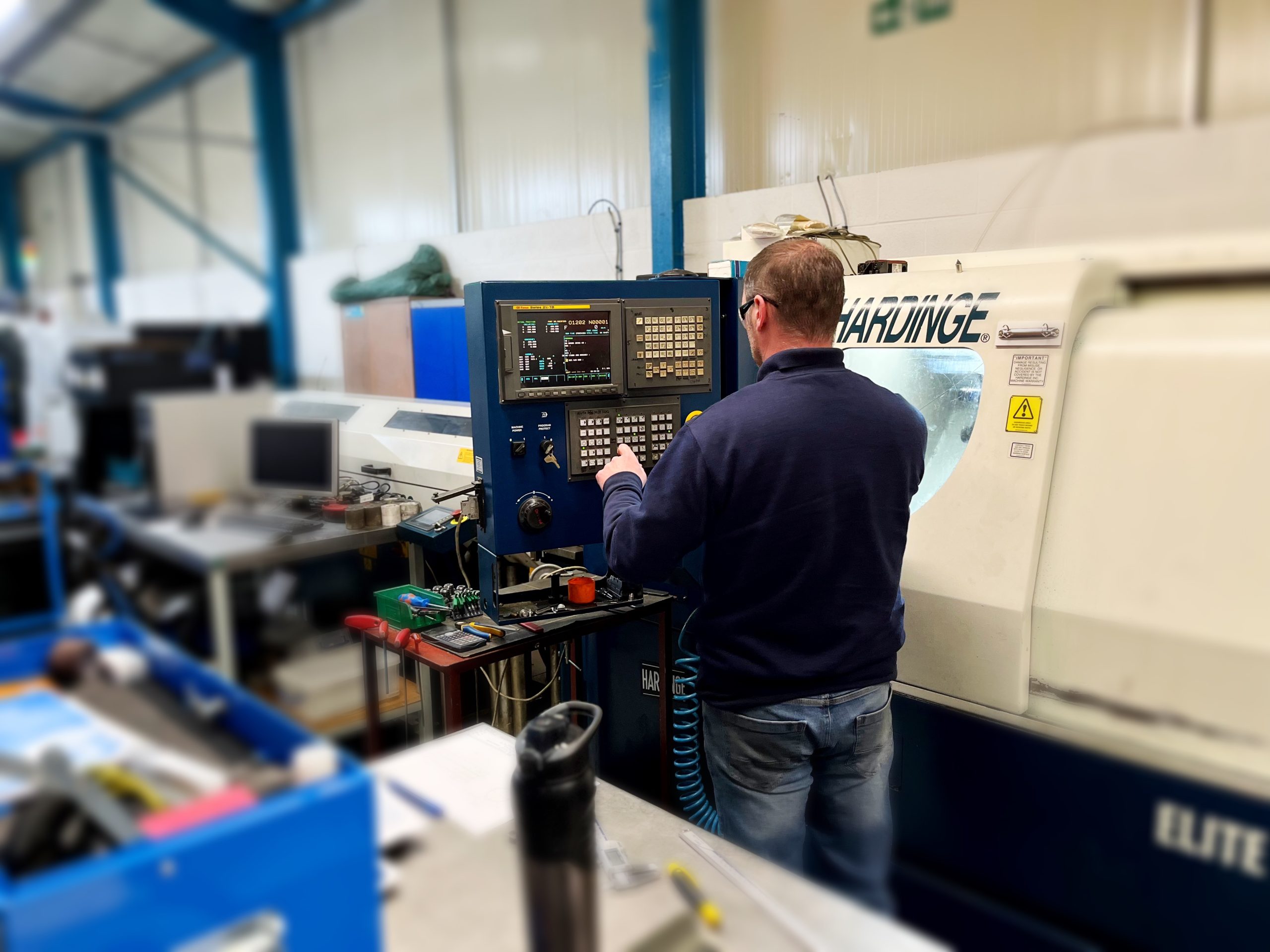

CNC Turning

In the CNC turning process, the plastic material is mounted on a rotating CNC lathe.

The cutting tool then removes excess material until the desired shape is achieved. This method is primarily used for crafting cylindrical shapes, although taper CNC turning allows for the creation of conical forms as well.

The Applications Of Plastic CNC Machining

CNC plastic machining plays a vital role across various industries, including automotive and motorsport, medical, oil and gas, aerospace, defence, and nuclear sectors. This versatile process can be utilised for a range of applications, such as:

- Production of lenses for cameras, telescopes, and microscopes.

- Plastic components for appliances used in the food and beverage industry.

- Medical devices, implants, and prosthetics.

- Parts for automobiles and aircraft.

- Electrical components for various devices and systems.

Its adaptability makes CNC plastic machining an essential tool in meeting the specific needs of these diverse fields.

The Advantages Of CNC Plastic Machining

CNC plastic machining brings numerous benefits to businesses and manufacturers, including:

- Precision: It stands out as the most accurate rapid prototyping method when compared to plastic injection moulding and 3D printing. Its level of accuracy ensures that future production runs are consistent and reliable.

- Complex Designs: CNC plastic machining excels in producing both simple and intricate designs. Thanks to the capability of CNC machines to cut along multiple axes, they outperform even 3D printing in creating complex shapes.

- Tight Tolerances: With their high precision, CNC machines can manufacture products to very tight tolerances, outperforming plastic injection moulding and 3D printing.

- Reduced Defects: The precision of CNC plastic machining results in significantly fewer defects compared to other production methods, enhancing product quality.

- Versatility: The method works with a wide variety of plastic polymers, making it adaptable for different applications.

- Minimal Waste: Fewer defects mean less waste of materials, which can lead to cost savings for your business.

- Flexibility: CNC plastic machining is capable of creating a broad range of products with various shapes and complexities, making it a highly flexible manufacturing option.

Our Quality Control

At Sotek Engineering, quality is our top priority. We utilise ISO 9001:2015-compliant quality management systems – combined with regular inspections and statistical process control (SPC) – to guarantee outstanding results for every project we undertake.

To find out more about our commitment to quality control, click here.

About Sotek Engineering

Founded in 2017 by Steve Brown and Oliver Cumbers, Sotek Engineering has quickly established itself as a reliable provider of CNC machining services across a wide range of industries.

Our skilled team leverages cutting-edge CNC technology and strict quality control processes to deliver flawless products that meet our clients’ needs.

Sotek Engineering was built on a straightforward vision: to support UK businesses by consistently providing high-quality machining, design, reverse engineering, and break-fix solutions. Our dedication to outstanding customer service has allowed us to forge long-lasting relationships with our clients.

Located in Newton Abbot, just off the main road that connects to the UK Motorway Network, we can easily facilitate same-day or next-day deliveries when needed.

We offer a comprehensive range of CNC services, including:

- CNC Machining

- CNC Routing

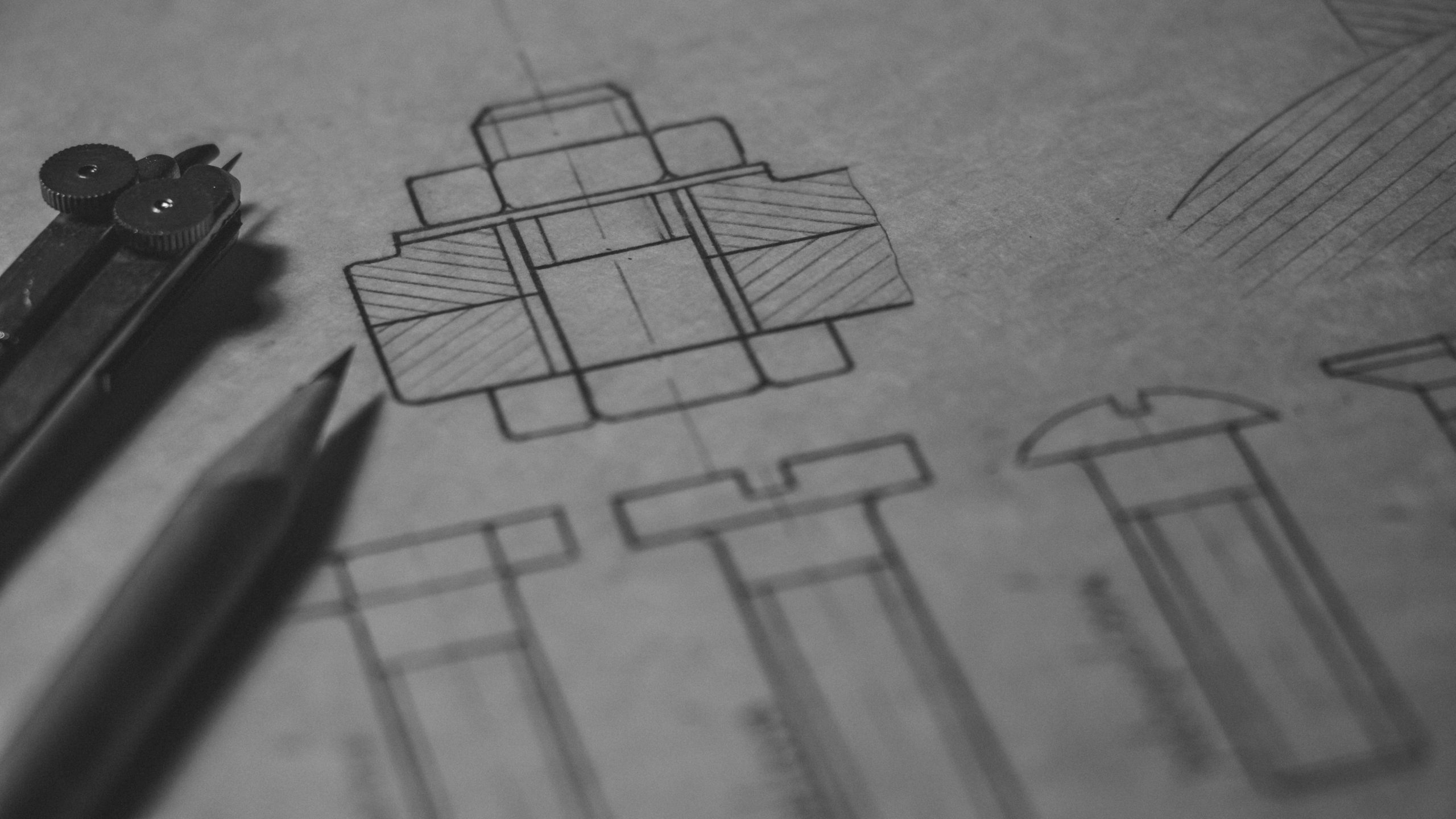

- Design

- Reverse Engineering

- Re-Engineering

Our Testimonials

Sotek Engineering was established on the foundation of 15 years of experience in the manufacturing industry.

Our expertise in producing perfectly finished CNC machined products has earned us the trust of blue-chip clients across a variety of sectors, including automotive and motorsport, medical, oil and gas, aerospace and defence, and nuclear.

The quality of our work speaks for itself—hundreds of satisfied clients have benefited from our services! You can check out their testimonials here.

Let's get started with your next project...