Sotek Engineering

CNC Milling UK

Looking For Top-Quality CNC Milling UK?

Contact Us!

At Sotek Engineering, we specialise in providing CNC milling services to UK clients across a wide range of industries, including automotive, motorsport, aerospace, medical, oil and gas, defence, and nuclear. We are dedicated to delivering high-precision subcontract machining, design, reverse engineering, and break-fix solutions that meet the highest standards.

Our commitment to excellence is evident in our use of cutting-edge technology and stringent quality control processes, ensuring we consistently produce bespoke parts of the highest quality. And as an ISO 9001:2015 certified company, we have built a reputation as a trusted partner for CNC milling services, delivering consistently excellent results for a wide range of sectors.

Our Services

CNC Milling UK

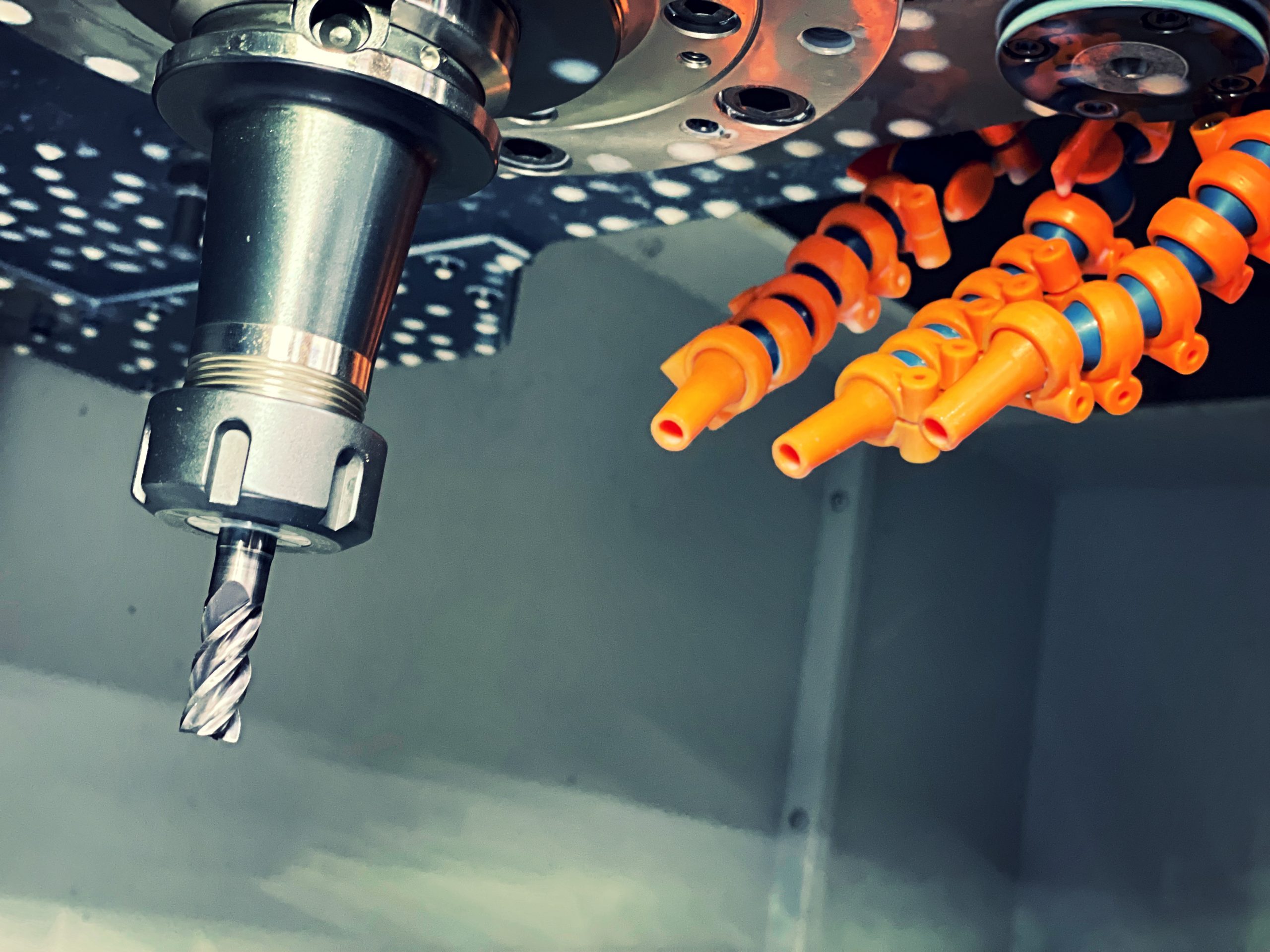

CNC Milling is a highly versatile machining process that utilises computer-controlled machines to create complex parts from a range of materials, including metals, plastics, and composites. The workpiece is secured on a machine bed while a rotating cutting tool removes material to create the desired shape.

This process is capable of moving along multiple axes (x, y, and z) and can be programmed to achieve precise features such as slots, holes, pockets, and contours. The use of advanced CNC milling machines allows for the creation of highly detailed and intricate parts with exceptional precision, all in a streamlined process that reduces lead times and maximises efficiency.

The Types Of CNC Milling Machines

At Sotek Engineering, we use a wide range of CNC milling machines for different project needs:

Horizontal Milling Machines: Equipped with a horizontal spindle, these machines move along the x and z axes, making them suitable for large or heavy components.

Vertical Milling Machines: These machines feature a vertical spindle that moves along the x and y axes, ideal for producing a variety of shapes and components.

5-Axis Milling Machines: These machines offer the ability to move along five axes, allowing the production of highly complex and detailed parts.

Gantry Milling Machines: These machines use a fixed bridge to move the cutting tool along multiple axes, perfect for large or intricate parts.

The Applications Of CNC Milling

CNC Milling is indispensable in industries requiring high-precision components, such as automotive, aerospace, medical, and defence.

These industries rely on the precision, speed, and versatility of CNC milling machines to create parts that meet stringent specifications.

The Benefits Of CNC Milling

CNC Milling offers a wide range of benefits, including:

Reduced Defects: Less reliance on manual processes reduces human error.

Improved Efficiency: Faster production speeds lead to reduced lead times.

Energy Efficiency: Optimised machine usage reduces energy consumption.

High Precision: Consistent accuracy and tight tolerances are achieved.

Lower Costs: The automation process results in reduced labour costs.

Enhanced Safety: Automated systems improve operator safety.

Minimal Waste: Efficient material usage reduces waste.

More Of Our CNC Machining Services

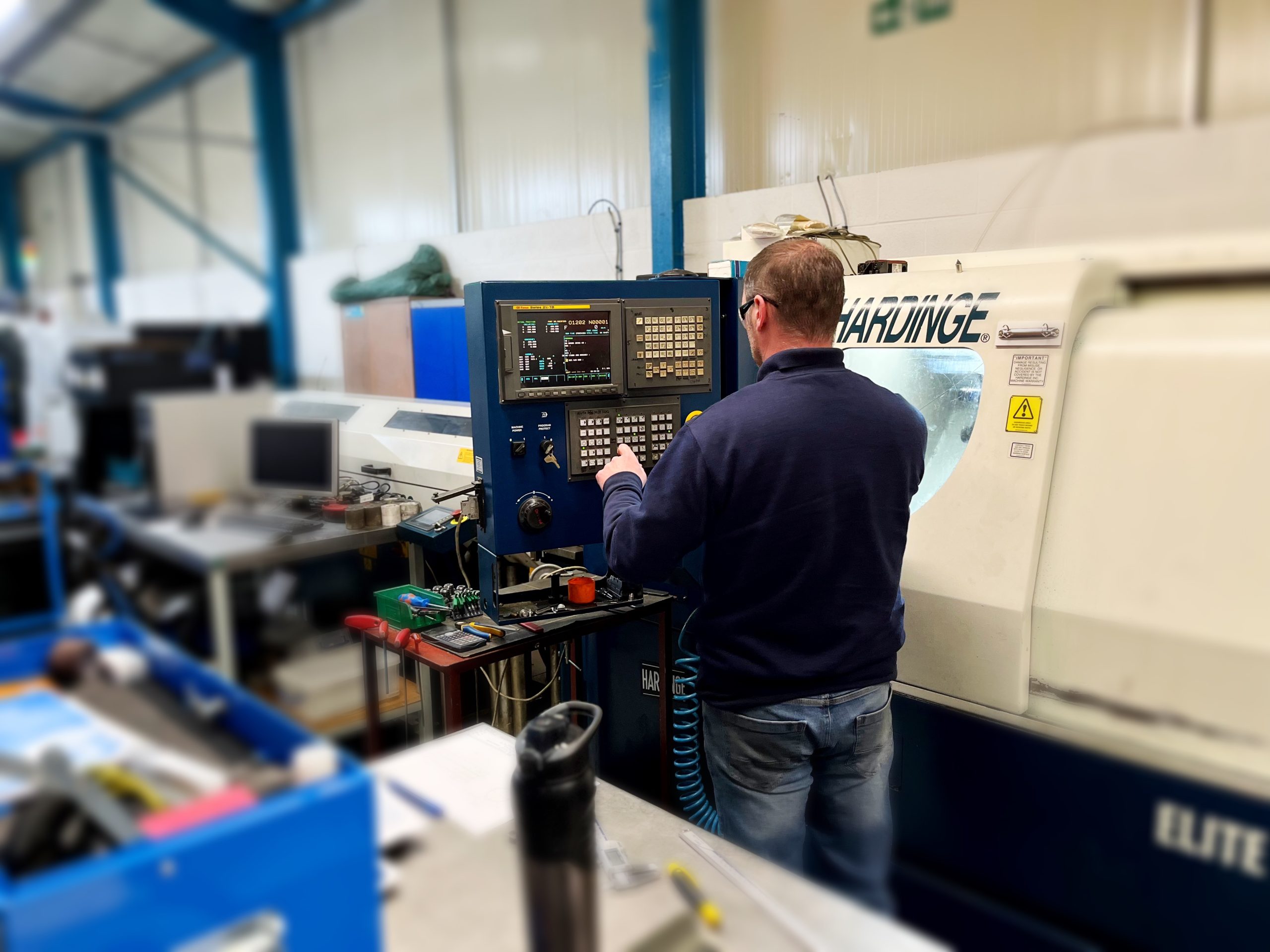

CNC Turning

CNC Turning is a process used to create cylindrical or conical parts by rotating the workpiece against a cutting tool. The lathe machine moves the cutting tool along the surface of the material to shape it into the desired form.

CNC Turning is ideal for producing parts with complex contours and is widely used across industries like automotive, aerospace, and medical.

The Features Of CNC Turning Machines

Bar Feeders: These devices automatically feed raw material into the machine, improving efficiency and eliminating the need for manual loading.

Driven Tooling: Driven tooling enables additional machining capabilities, such as drilling, tapping, and milling, expanding the range of features that can be added to the part.

The Applications Of CNC Turning

CNC Turning is widely used to manufacture parts for the automotive, aerospace, medical, and defence industries.

The efficiency, flexibility, and precision of CNC turning machines make them ideal for producing both simple and complex parts quickly and accurately.

The Benefits Of CNC Turning

The advantages of CNC Turning include:

Versatility: Capable of handling various materials, including metals, plastics, and composites.

Cost-Effective: Reduced waste and shorter cycle times lower overall production costs.

Improved Safety: Reduced operator involvement leads to a safer working environment.

Increased Production Speed: Reduced lead times due to faster operations.

Enhanced Precision: Tight tolerances ensure a high-quality finish.

Why Choose Us For CNC Milling UK?

With more than 15 years of experience, Sotek Engineering has built an extensive portfolio, serving over 100 satisfied clients across various industries.

Time and time again, our customers choose us for our:

Comprehensive Services: We handle everything from design to final delivery, making us a one-stop shop for all CNC milling needs.

Customer-Centred Approach: We work closely with clients to understand their needs and deliver tailored solutions.

Speed And Efficiency: Our advanced equipment and processes allow us to deliver fast and reliable results.

Exceptional Quality: We guarantee the highest standards of precision and attention to detail.

Thanks to our expertise and commitment, we’ve consistently received glowing feedback from our valued customers. Check out our testimonials to see what they have to say!

Our Quality Control

At Sotek Engineering, customer satisfaction is the cornerstone of our business. We operate under the ISO 9001:2015 quality management system to ensure consistent excellence in every part we produce. This commitment to quality control is integrated throughout our process, from initial design to final inspection.

We employ statistical process control (SPC), regular inspections, and rigorous testing to ensure the highest level of precision. Our focus on quality has earned us the trust of many industries and helped build long-term relationships with our clients.

About Sotek Engineering

Founded in 2017 by Steve Brown and Oliver Cumbers, Sotek Engineering was created with a clear goal: to deliver exceptional subcontract machining services to businesses across the UK. With our commitment to using the latest technology and maintaining the highest standards of quality control, we have built a reputation for precision and reliability in our field.

Located in Newton Abbot, our convenient location allows us to offer quick turnaround times, including same-day and next-day deliveries, ensuring that your projects are completed on schedule.

We offer a comprehensive range of services, including:

- Reverse Engineering

- Re-engineering

- CNC Routing

- CNC Turning

- CNC Milling

- Design

Contact Us If You’re Looking For Top-Quality CNC Milling UK!

If you’re looking for a custom CNC milling partner with a proven track record of excellence, Sotek Engineering is here to help. With our comprehensive services and commitment to quality, we are your go-to provider for CNC milling, CNC turning, and much more!

Get in touch today to discuss your project and discover how we can support your CNC milling needs with precision, efficiency, and reliability.

Let's get started with your next project...