Sotek Engineering

CNC Milling Service UK

Looking For Top-Quality CNC Milling Services UK?

Contact Us!

At Sotek Engineering, we specialise in delivering premium CNC Milling Services tailored to meet the needs of our UK clients across various industries, including the automotive and motorsport, medical, oil and gas, aerospace, defence, and nuclear sectors. Our commitment to providing high-quality machining, design, reverse engineering, and break-fix solutions has earned us a trusted reputation throughout the CNC milling industry.

We understand the importance of precision and reliability in the products we create, which is why we use the latest technological advancements and adhere to rigorous quality control standards.

As an ISO 9001:2015 certified company, we take pride in our consistent ability to meet and exceed the expectations of our clients, which is reflected in our excellent satisfaction ratings and many positive reviews.

Our CNC Milling Services UK

CNC Milling

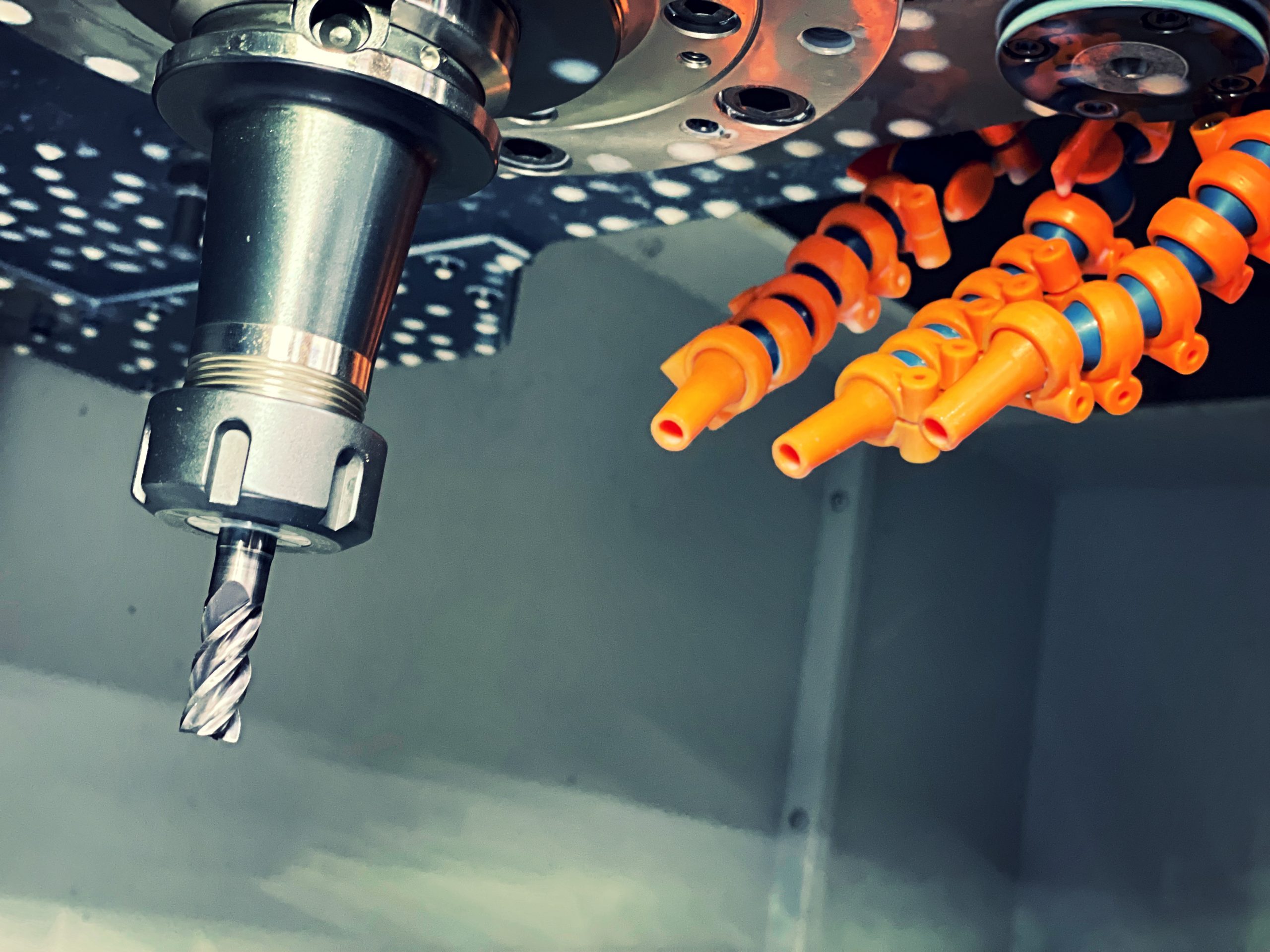

CNC Milling is a versatile machining process that utilises a computer-controlled machine tool to produce precise and complex parts from various materials, such as metals, plastics, and composites. The workpiece is securely fixed to a worktable, and the cutting tool moves along multiple axes to remove material and create the desired shape.

Our CNC milling machines can move along the x, y, and z axes, enabling the creation of intricate features like holes, slots, pockets, and contours. These machines use advanced software and automation to achieve exceptional accuracy and precision. The cutting tools, such as end mills, drills, and taps, are specifically chosen to meet the unique requirements of each project.

The Types Of CNC Milling Machines

At Sotek Engineering, we operate a range of CNC milling machines, each designed for different levels of complexity and precision:

Vertical Milling Machines: These machines use a vertical spindle that moves up and down along the x and y axes, perfect for creating a variety of shapes.

Horizontal Milling Machines: These machines use a horizontal spindle that moves side-to-side along the x and z axes, ideal for producing large or heavy parts.

5-Axis Milling Machines: These machines move the cutting tool along five axes, allowing for the creation of highly complex and detailed parts with superior precision.

Gantry Milling Machines: These machines use a fixed bridge to span the workpiece and move the cutting tool along multiple axes, offering enhanced accuracy for large parts.

The Applications Of CNC Milling

CNC milling machines are widely used in industries such as automotive, aerospace, medical, and defence, where precision and quality are paramount. Their ability to produce high-precision parts quickly and efficiently makes them invaluable in these sectors.

The Benefits Of Our CNC Milling Service UK

Our CNC Milling service offers several key advantages for the manufacturing process, including:

Energy Efficiency: Reduced energy consumption compared to traditional methods.

Reduced Defects: Decreasing the likelihood of human error during production.

Faster Production: Enhancing manufacturing efficiency and speed.

Lower Costs: Overall cost reductions due to efficient production.

Improved Safety: Automated processes minimise operator risk.

High Precision: Achieving tight tolerances and fine details.

Minimal Waste: Optimising material usage.

More Of Our CNC Machining Services

CNC Turning

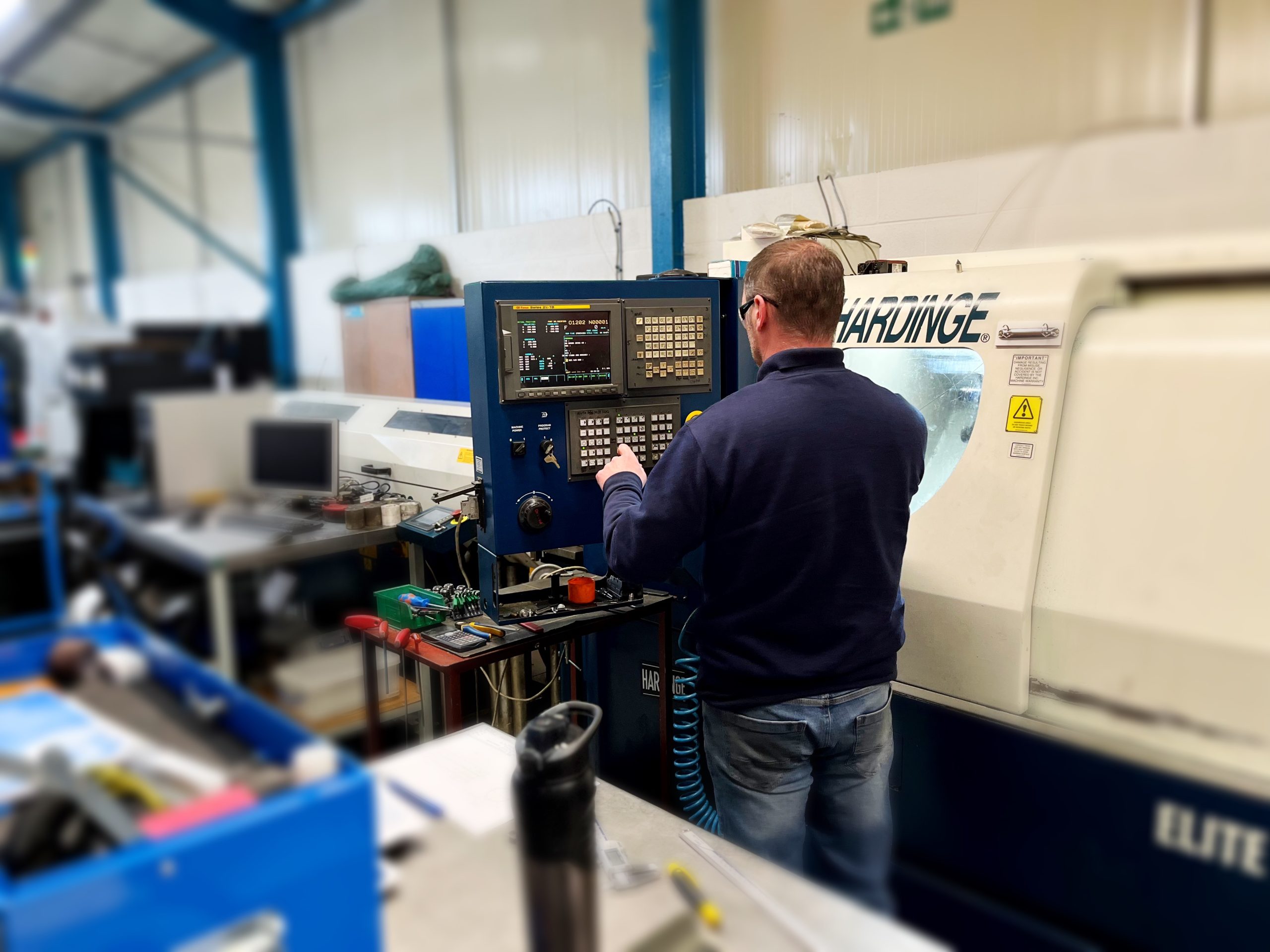

CNC Turning is a machining process used to create cylindrical or conical parts by rotating the workpiece against a cutting tool, with the cutting tool moving along the surface of the material to shape it into the desired dimensions. CNC Turning can be used for various functions such as facing, drilling, threading, and grooving.

Our CNC Turning machines work with a wide range of materials, including metals, plastics, and composites, and are renowned for producing parts with exceptional speed and precision.

The Features Of CNC Turning Machines

Bar Feeder: This component automatically feeds raw materials such as metal bars into the CNC lathe, increasing efficiency by eliminating manual loading.

Driven Tooling: Driven tooling enables multiple operations, including drilling, tapping, and milling, thereby expanding the machine’s capabilities and reducing cycle time.

The Applications Of CNC Turning

CNC Turning is used in many industries, including automotive, aerospace, medical, and defence.

The flexibility and precision offered by CNC Turning make it ideal for manufacturing small and medium-sized parts that require high accuracy.

The Benefits Of CNC Turning

CNC Turning offers several advantages, such as:

Fast Production: Reduces the time it takes to manufacture parts.

High Precision: Maintains tight tolerances with minimal errors.

Safety: Reduces manual handling and improves safety.

Flexible: Suitable for both simple and complex parts.

Reduced Waste: Maximises material efficiency.

Cost-Effective: Lower overall production costs.

Why Choose Us For CNC Milling Services UK?

Over the years, we have built a reputation for delivering flawlessly finished products across a variety of sectors, including medical, aerospace, and defence industries.

With over 15 years of experience, we are proud to have served more than 100 satisfied clients, consistently earning positive feedback for our commitment to high standards of accuracy and quality.

Our longstanding track record speaks for itself, making us a trusted supplier to businesses requiring precision-engineered components.

Our Quality Control

At Sotek Engineering, quality is at the heart of everything we do. We operate an ISO 9001:2015 compliant quality management system, ensuring that we consistently deliver products that meet the highest standards.

We embed quality control into every stage of our process, from design to final delivery, to ensure that our clients receive top-quality products every time.

Plus, our use of statistical process control (SPC) and regular inspections ensures that we maintain strict quality standards throughout the production process.

About Sotek Engineering

Sotek Engineering was founded in 2017 by Steve Brown and Oliver Cumbers, who had a vision to deliver high-quality subcontract machining services to industries across the UK.

Since then, we have earned a reputation for excellence, providing CNC turning, CNC milling, and a host of other engineering services, including design, reverse engineering, and re-engineering.

Located in Newton Abbot, we are strategically positioned to facilitate same-day or next-day deliveries, helping our clients meet tight deadlines and production schedules.

Contact Us If You’re Looking For A Top-Quality CNC Milling Service UK!

If you need high-quality CNC milling services tailored to your specific requirements, Sotek Engineering is here to help.

Whether you’re in the automotive, aerospace, medical, or defence industries, our CNC milling and CNC turning services are designed to meet your precision needs.

Get in touch with us today!

Let's get started with your next project...