Sotek Engineering

CNC Milling & Turning

Looking For Top-Quality CNC Turning And Milling?

Make Sure You Contact Us!

At Sotek Engineering, we specialise in providing high-quality, precision-driven CNC milling and turning services to meet the needs of our discerning clients. Through a commitment to excellence, advanced technology, and our highly skilled workforce, we offer CNC solutions perfect for industries such aerospace, automotive, medical, and more.

Whether you need intricate, one-off components or large-scale production runs, Sotek Engineering is the partner you can rely on for consistent quality!

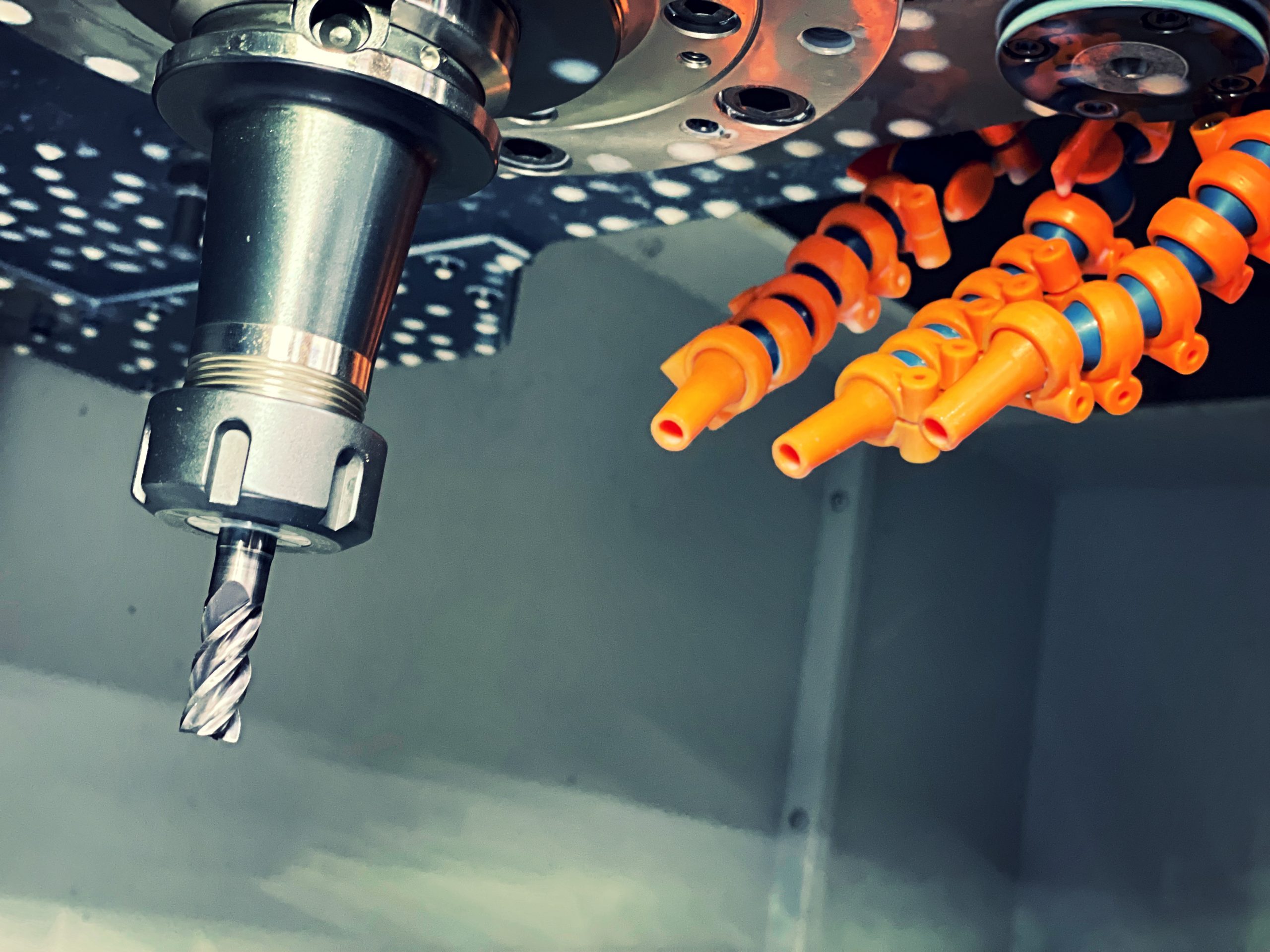

CNC Milling: High-Precision Machining For Complex Components

CNC milling is a vital process for producing components with complex geometries and high dimensional accuracy.

At Sotek Engineering, our state-of-the-art 3, 4, and 5-axis CNC milling machines enable us to handle projects with the highest level of precision. This capability allows us to create parts that feature intricate details, tight tolerances, and a smooth surface finish, all in a single operation.

Our CNC milling services are suitable for a variety of applications, from prototyping to full-scale production. The ability to machine components with multiple axes ensures that we can create parts that would typically require many setups using traditional methods.

Whether you are looking for parts with detailed contours or large-scale flat components, our advanced milling technology ensures that all parts are manufactured to your precise specifications.

Our team at Sotek Engineering is highly skilled in machining a range of materials, from metals such as stainless steel, aluminium, and titanium, to plastics and composites. We understand the nuances of each material and its properties, ensuring that the correct approach is applied to achieve the best results. With expertise in working with both ferrous and non-ferrous materials, we offer a versatile solution for a wide range of industries.

For sectors like aerospace, medical devices, automotive, and electronics, precision and quality are paramount. Sotek Engineering’s CNC milling services are trusted to deliver components that meet the strict standards of these industries.

For example, in the aerospace industry, where parts must endure extreme conditions and adhere to rigorous safety standards, we produce lightweight, high-performance components with the utmost care.

Similarly, in the medical field, where even the smallest deviation can affect a device’s functionality, our services ensure that each part is crafted with exacting precision.

CNC Turning: Efficient Production Of Round Components

CNC turning is an essential method for producing cylindrical or conical parts that require high precision and surface finish.

At Sotek Engineering, we utilise advanced CNC turning machines to create complex, high-quality components with a high level of accuracy. Whether you need simple shafts or more detailed, multi-featured parts, our turning services are designed to meet the precise demands of your project.

The CNC turning process is particularly well-suited for high-volume production, where efficiency and consistency are critical. Our CNC lathes offer the ability to produce a wide range of round components with intricate features, such as threading, grooves, and stepped diameters. Each part is carefully machined to ensure it meets exact specifications, with tolerances often as tight as 0.005mm.

As with our CNC milling services, the materials we work with in CNC turning are highly versatile, ranging from stainless steel, aluminium, and brass, to various plastics. For industries like automotive and oil & gas, where parts must withstand highly challenging environments, our CNC turning services provide the necessary reliability and performance. For instance, components like camshafts, valve bodies, and precision gears are manufactured with the attention to detail needed to ensure they function as intended in high-stress applications.

And in the medical field, where part reliability and dimensional accuracy are crucial, CNC turning is used to create surgical instruments, implants, and housings for medical devices. Our ability to maintain consistent quality in high-volume production runs ensures these components meet the stringent regulations required by the sector.

Why Choose Sotek Engineering For CNC Milling And Turning?

Why Choose Sotek Engineering For CNC Turning And Milling?

Choosing us for your CNC milling and turning needs ensures that you receive not only precise and reliable components but also an experience grounded in expertise and commitment to quality. Our team will work closely with you to understand the specific requirements of your project, providing tailored solutions for your needs.

At Sotek Engineering, we are equipped with the latest in CNC machinery, allowing us to handle a wide variety of machining projects. Our 3, 4, and 5-axis CNC milling machines can produce highly detailed parts with multiple complex features in a single operation. This advanced equipment, combined with our skilled engineers, ensures that we can meet even the most demanding machining tasks, whether your project involves prototyping or large-scale production.

With years of experience working across multiple industries, we have developed a deep understanding of the unique needs of sectors such as aerospace, automotive, medical devices, and more. This means our engineers have the knowledge and technical expertise to select the appropriate machining process – whether milling or turning – to ensure that every part meets the required specifications.

We also take pride in our commitment to excellence, adhering to stringent quality control measures throughout the manufacturing process and using advanced inspection techniques to ensure that each component meets your exact requirements. We also understand the importance of timelines and budgets, which is why we focus on providing timely deliveries and cost-effective solutions without compromising on quality.

Plus, we understand that every project is unique, which is why we offer personalised solutions to achieve the best possible outcomes. From the initial design stage to the final delivery, our team works closely with clients to ensure that every aspect of the project meets expectations.

The Industries We Serve With CNC Milling & Turning

Our CNC milling and turning services cater to a wide array of industries, each requiring precision-engineered components that meet rigorous standards.

Just some of the sectors that we support include:

Aerospace: The aerospace industry requires parts that not only meet high-performance specifications but also adhere to strict safety standards. At Sotek Engineering, we produce precision components from materials like titanium and aerospace-grade aluminium that can withstand extreme conditions and ensure the safety and efficiency of aircraft systems.

Automotive: In the automotive sector, we supply parts that play critical roles in engine performance, vehicle safety, and overall functionality. Our CNC milling and turning services support manufacturers with components like engine blocks, camshafts, gears, and transmission parts, all of which require precise machining.

Medical Devices: For medical devices and equipment, precision is crucial. We work with manufacturers of surgical instruments, implants, and medical device housings to create components that meet regulatory standards and function effectively in critical applications.

Oil And Gas: In the oil and gas industry, components must be engineered to withstand extreme conditions, including high pressures and temperatures. Our CNC machining services produce parts used in pumps, valves, and turbines that ensure the reliability and safety of critical oilfield equipment.

Electronics: The electronics industry demands high precision for components like enclosures, connectors, and housings. Our CNC services provide the necessary accuracy to ensure that each part fits precisely and functions optimally in electronic devices.

About Sotek Engineering

Founded in 2017 by Steve Brown and Oliver Cumbers, Sotek Engineering was built on the straightforward but impactful goal of providing premium-quality subcontract machining, design, reverse engineering, and repair solutions to businesses throughout the UK.

We pride ourselves on being a trusted provider of CNC turning services across multiple industries. By combining advanced technology, rigorous quality control processes, and a strong focus on customer service, we’ve earned a reputation for delivering flawless products, every time.

Based in Newton Abbot, we are conveniently located just off a major road connecting to the UK Motorway Network, enabling us to offer same-day or next-day deliveries when needed.

The wide range of CNC services we provide includes:

- CNC Routing

- CNC Milling

- Design

- Reverse Engineering

- Re-Engineering

Get In Touch!

If you require precision CNC milling or turning services, we’re the perfect solution for your project. Our combination of advanced technology, industry expertise, and commitment to quality ensures that your components will meet your exact specifications every time. To discuss your requirements or request a quote, contact us today.

Contact Us If You Need Top-Quality CNC Milling And Turning!

Contact Us If You Need Top-Quality CNC Turning And Milling!

Let's get started with your next project...