Sotek Engineering

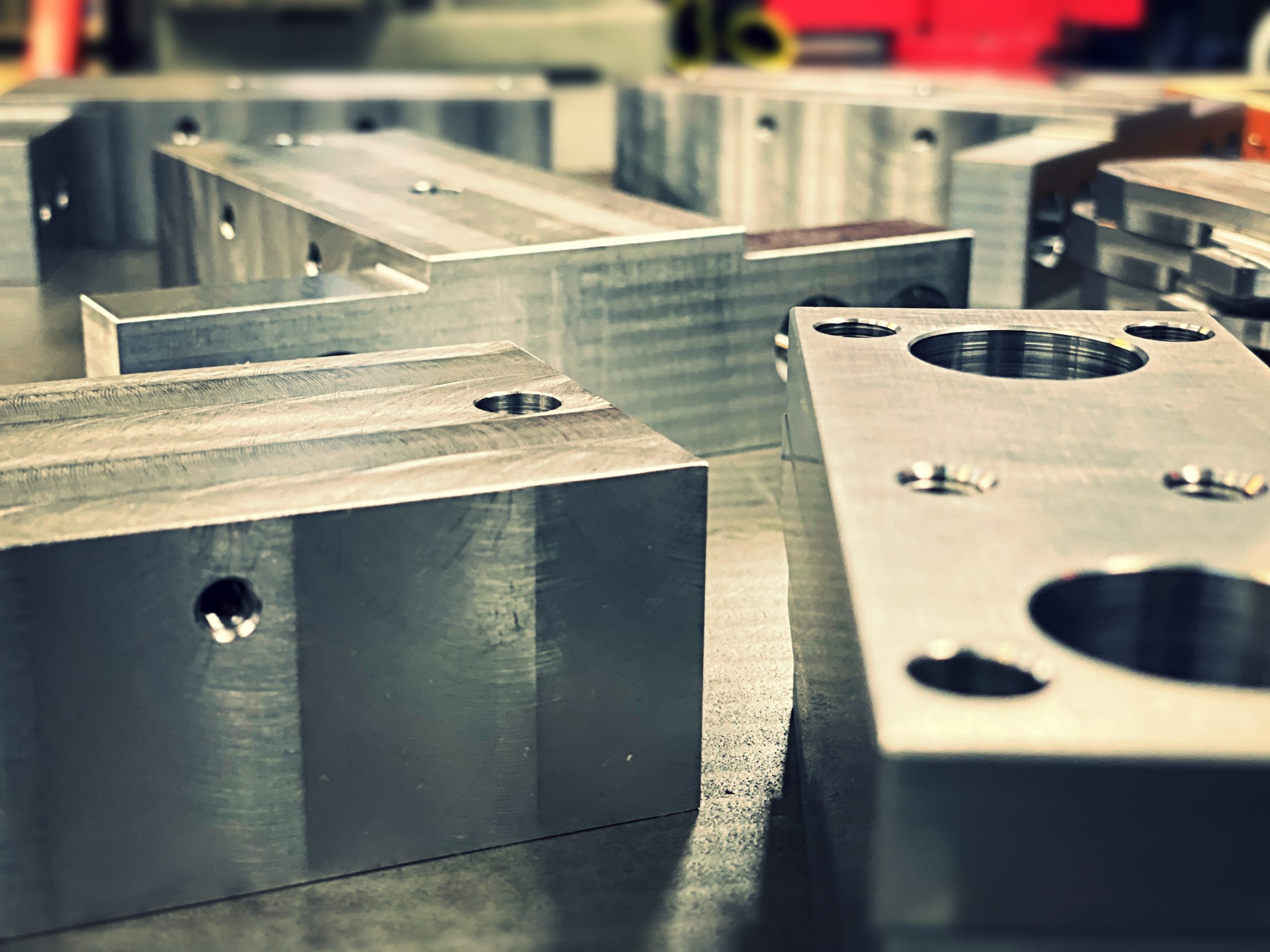

CNC Metal Cutting

Looking For A Top-Quality CNC Metal Cutting Service?

Contact Us!

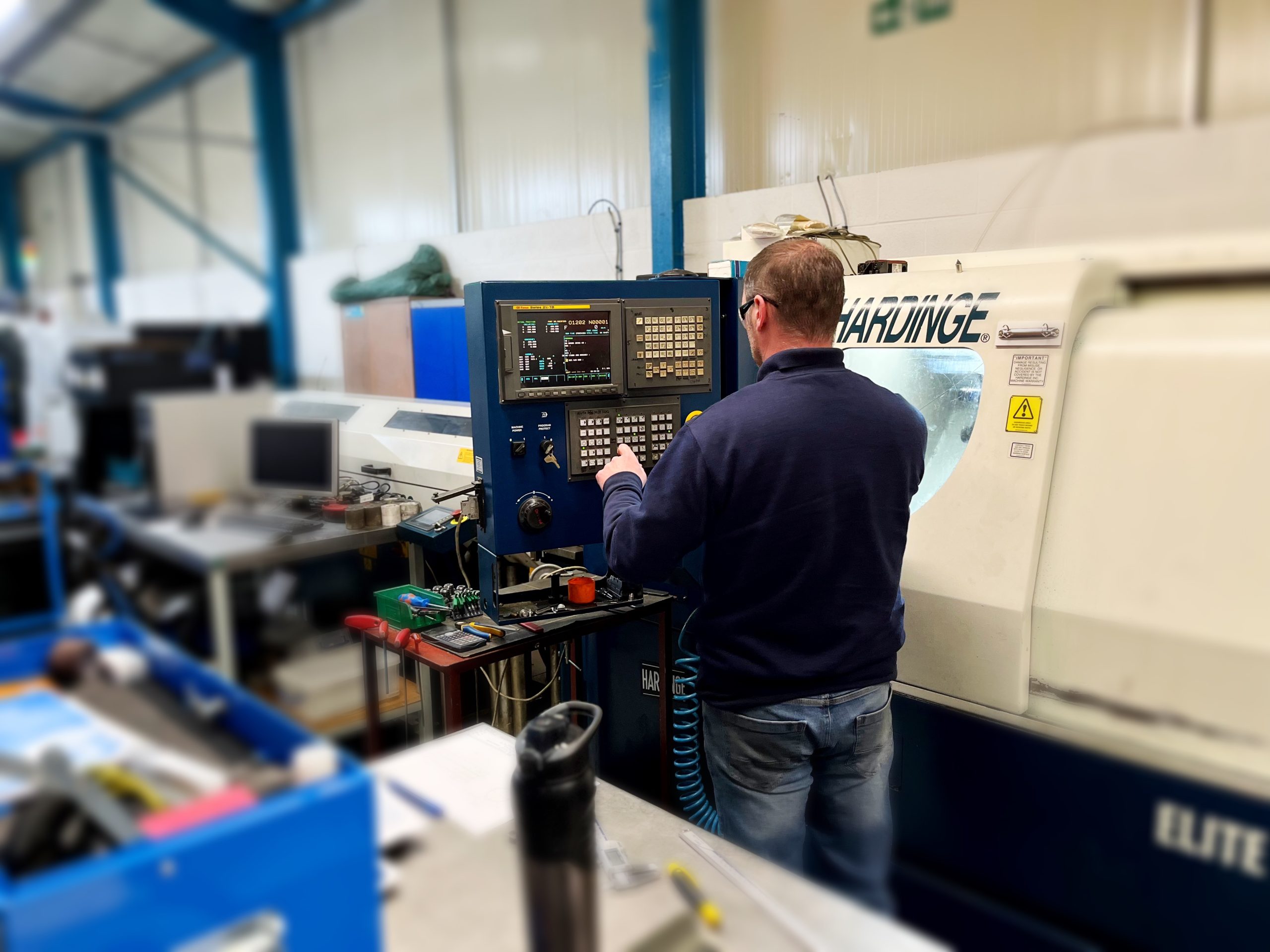

At Sotek Engineering, we are specialists in CNC Machining for metal fabrication. We provide our CNC metal cutting services to a wide range of industries, including Automotive and Motorsport, Medical, Oil and Gas, Aerospace and Defencing, and Nuclear.

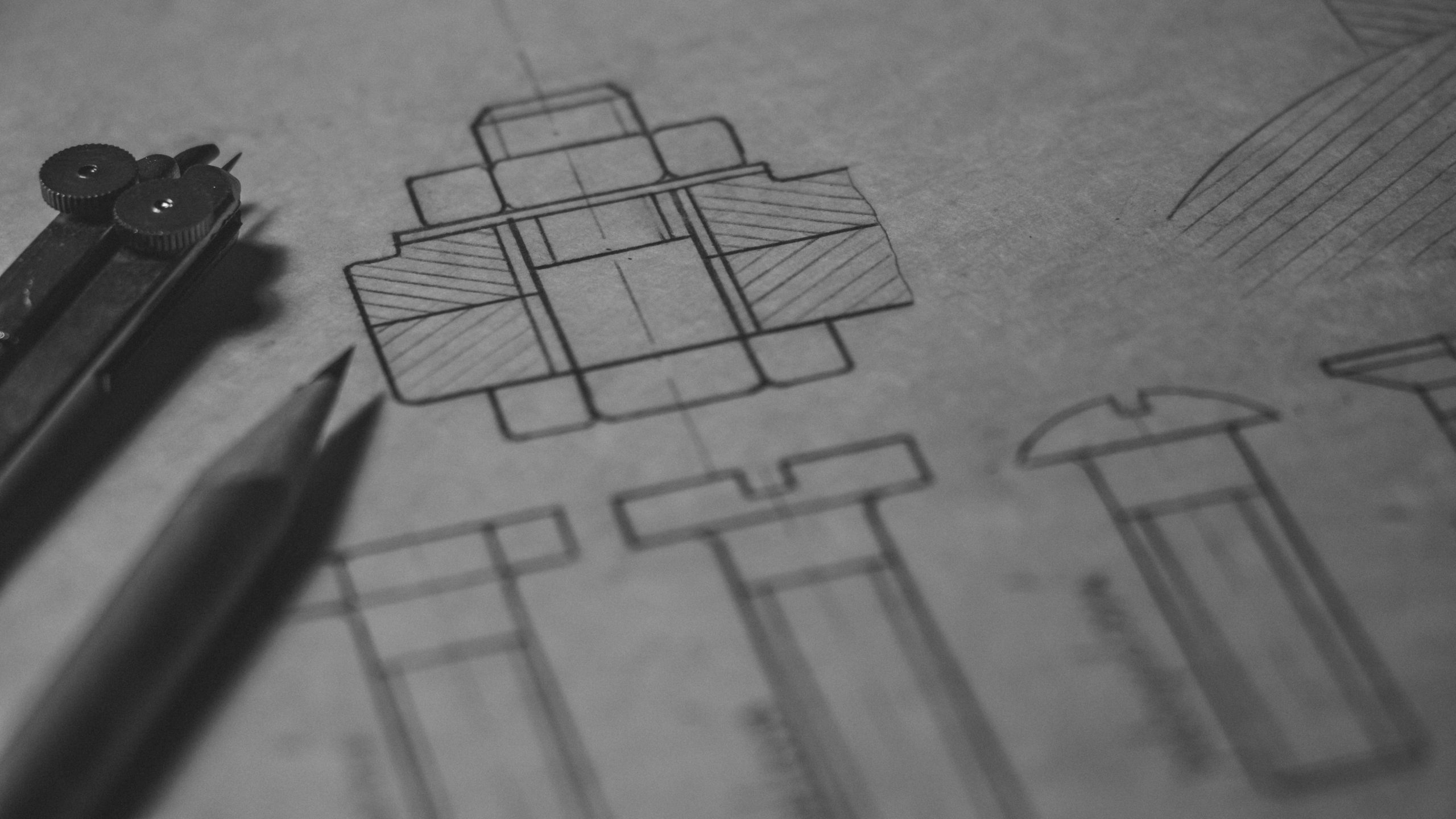

We deliver high-quality subcontract machining, design, reverse engineering, and break-fix solutions, using a client-centred approach to meet the exacting specifications of our diverse clientele.

Fully compliant with ISO 9001-2015 specifications and operating under strict quality control and responsible management processes, we harness state-of-the-art CNC machining technology to ensure excellent outcomes for all our clients.

Choose Sotek Engineering and gain access to the latest CNC machining technology for premium-quality results every time!

About CNC Metal Cutting

What Is CNC Machining For Metals?

CNC machining is used in the production of a wide range of metal products, making it a popular choice for manufacturers in a variety of industries.

CNC machining has revolutionised the metals industry with its ability to create metal products faster and more efficiently. Compared with metal injection moulding and even 3D printing, CNC machining is significantly more accurate, helping to reduce errors and waste products.

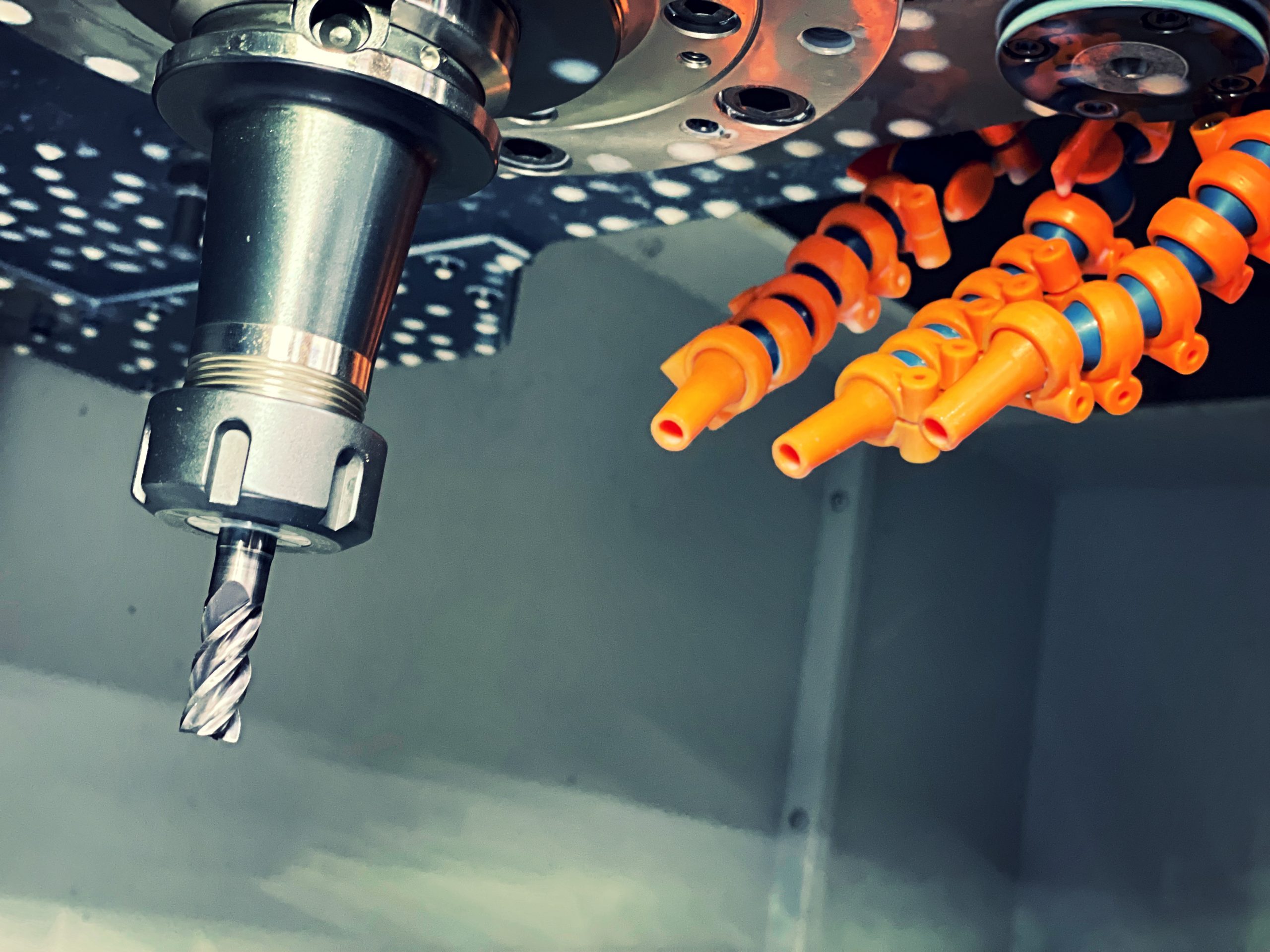

CNC machining is classed as a ‘subtractive process’. Directed by programs written in computer-readable languages such as G-code and M-code, a computer-controlled machine cuts away excess product from the workpiece to form the desired shape, dimensions, and features. This can be used to create complex and precise parts from a wide range of metals and metal alloys.

CNC machining is most commonly used for metals including Aluminium 7075, brass, Magnesium AZ31, Stainless Steel 303, 304, and 316, Carbon Steel 1045, and Titanium. Following the initial cutting stage, the CNC machine can then subsequently be used for assembly and finishing processes.

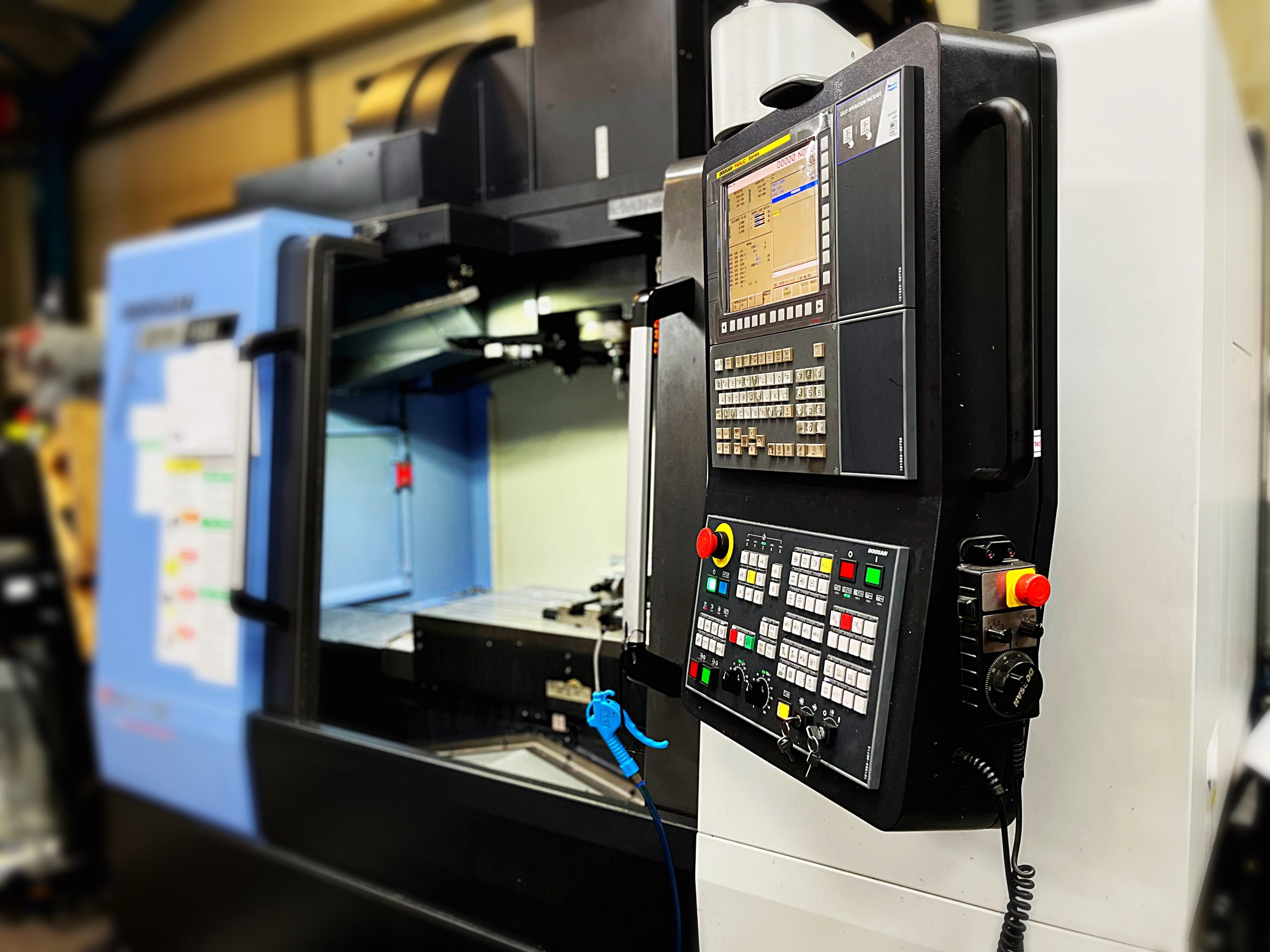

Two main types of CNC machining are used for metal fabrication – CNC Milling and CNC Turning.

CNC Milling

CNC Milling is predominantly used to create metal products with flat surfaces, angular faces, slots, pockets, threads, and patterns.

The first stage of CNC milling for metals involves fastening the metal workpiece to a table. The CNC then machine uses rapidly rotating cutting tools to accurately cut away excess material, forming the shape of the desired product according to the instructions supplied by the CNC program.

The cutting tool is capable of moving along the X, Y and Z axes to create a wide range of complex shapes and features, including flat and irregular shapes.

CNC Turning

In contrast to CNC Milling, CNC Turning is used to create cylindrical products. Conical shapes can also be created using a taper CNC turning process.

First, the metal is attached to a rotating CNC lathe. The CNC machine then uses a rotating cutting tool to cut away from the product until it matches the design specifications supplied by the CNC program.

The Applications Of CNC Machining For Metal Fabrication

CNC Machining is used to create metal products for multiple sectors, such as Automotive and Motorsport, Medical, Oil and Gas, Aerospace and Defensive, and Nuclear.

This process can be used to create a wide range of metal products including:

- Industrial machine components

- Automobile and aircraft parts

- Medical and dental devices and implants

- Electrical components

- Household products, fixtures, and appliances such as ovens, refrigerators, fences and gates

The Advantages Of CNC Machining For Metal Fabrication

CNC machining is the most accurate and versatile production process available to manufacturers working with metal products. This process offers our clients several advantages, including:

- Precision – CNC Machining is the most accurate rapid prototyping method, even when compared with metal injection moulding and 3D printing. This level of precision helps to prevent wasted resources and ensures repeatability for future production runs

- Complex Designs – CNC machines run along multiple axes, allowing them to create both simple and complex designs. CNC machines can handle complex designs even more effectively than 3D printers!

- Tight Tolerances – CNC machines are capable of manufacturing products to tight tolerances, thanks to their high levels of precision. In fact, they are superior to either metal injection moulding or 3D printing in this regard

- Versatility – CNC Machining can be used to create products from a wide range of metals and metal alloys

- Reduced Defects – CNC Machining produces significantly fewer defects than other production methods

- Minimal Waste – CNC machining produces fewer defects than other production methods, resulting in less waste and higher cost savings

- Flexibility – CNC Machining can be used to create products with a wide variety of shapes, sizes, and features

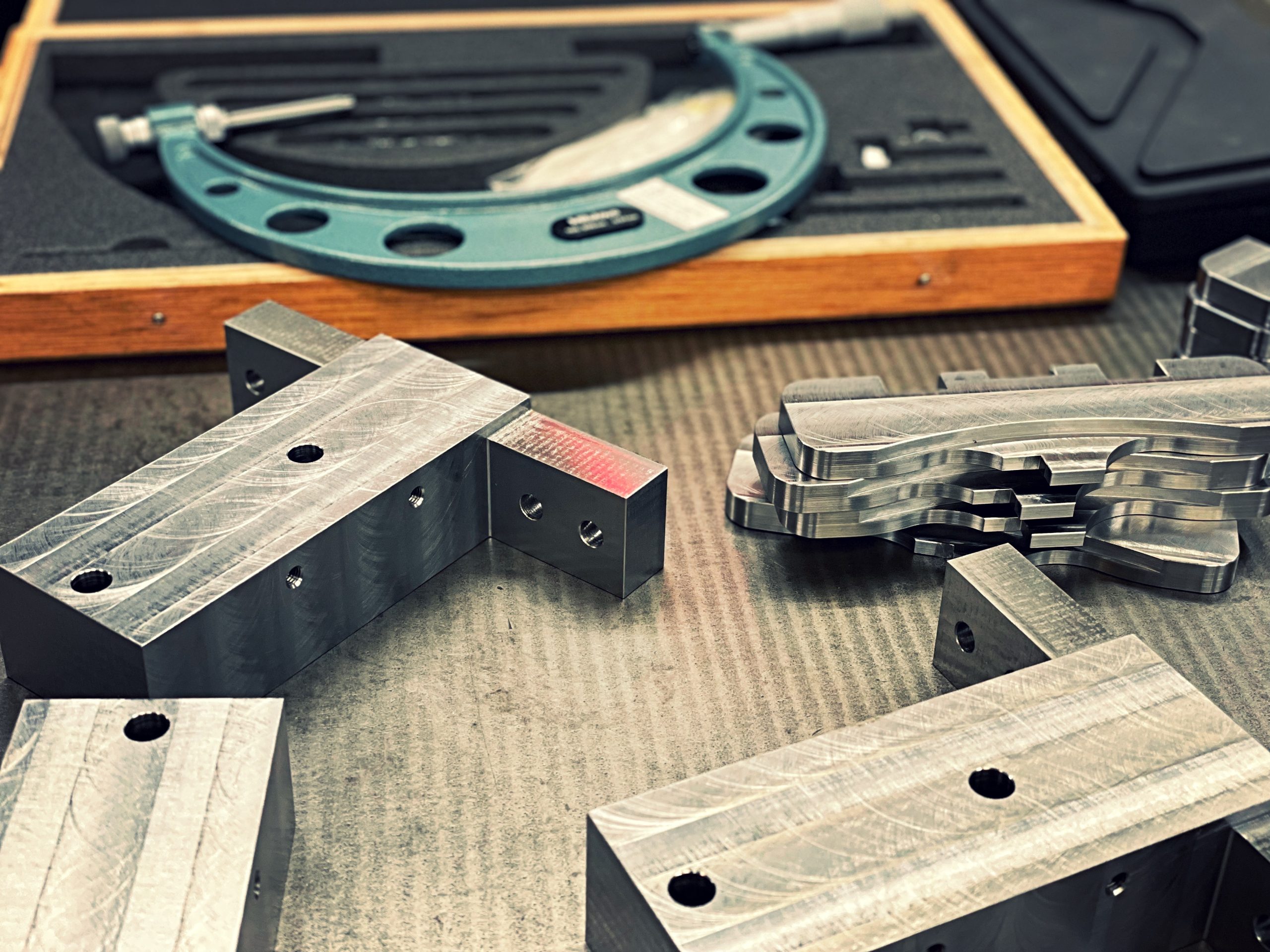

Our Quality Control

At Sotek Engineering, we are proud to be a trusted supplier of CNC Machining Services to multiple UK sectors. We have achieved this reputation by delivering consistently excellent results for our clients, many of whom have become repeat customers due to their satisfaction with our services.

At Sotek Engineering, we understand that exceptional outcomes require rigorous quality control standards. That’s why we use ISO 9001-2015 compliant quality management systems alongside statistical process control (SPC) and routine inspections to enable us to achieve the quality standards required by our clientele.

You can learn more about our commitment to quality control here.

About Sotek Engineering

Established in 2017 by Steve Brown and Oliver Cumbers, Sotek Engineering is a trusted provider of CNC Machining services to a wide range of services. Our experienced team harnesses state-of-the-art CNC technology – alongside rigorous quality control processes – to deliver faultless products to our clients.

Sotek Engineering was created with a simple vision in mind; to meet the needs of UK businesses by delivering consistently high-quality machining, design, reverse engineering, and break-fix solutions. Our enduring commitment to achieving superior customer service has enabled us to form long-lasting professional relationships with our clientele.

We are conveniently situated in Newton Abbot, directly off the main arterial road which connects to the UK Motorway Network. This location facilitates same-day or next-day deliveries of parts as required.

At Sotek Engineering, we offer a comprehensive range of CNC services, including:

- CNC Machining

- CNC Routing

- Design

- Reverse Engineering

- Re-Engineering

Our Testimonials

At Sotek Engineering, we have built our name on a background of 15 years in the manufacturing industry.

Our expertise in creating premium-quality CNC machined products has earned us a reputation as a trusted supplier to high-value clients in a wide range of industries including Automotive and Motorsport, Medical, Oil and Gas, Aerospace and Defensive, and Nuclear.

And our results speak for themselves – we have served hundreds of satisfied clients! You can read their testimonials here.

Contact Us If You’re Looking For A Top-Quality CNC Metal Cutting Service!

Contact Us If You’re Looking For Top-Quality CNC Metal Cutting!

Let's get started with your next project...