Sotek Engineering

CNC Machine Tool Services

Looking For Top-Quality CNC Machine Tool Services?

Contact Us!

At Sotek Engineering, we specialise in CNC machine tool services tailored to clients across a wide range of industries – from automotive and motorsport, to medical, oil and gas, aerospace, defence, and nuclear sectors.

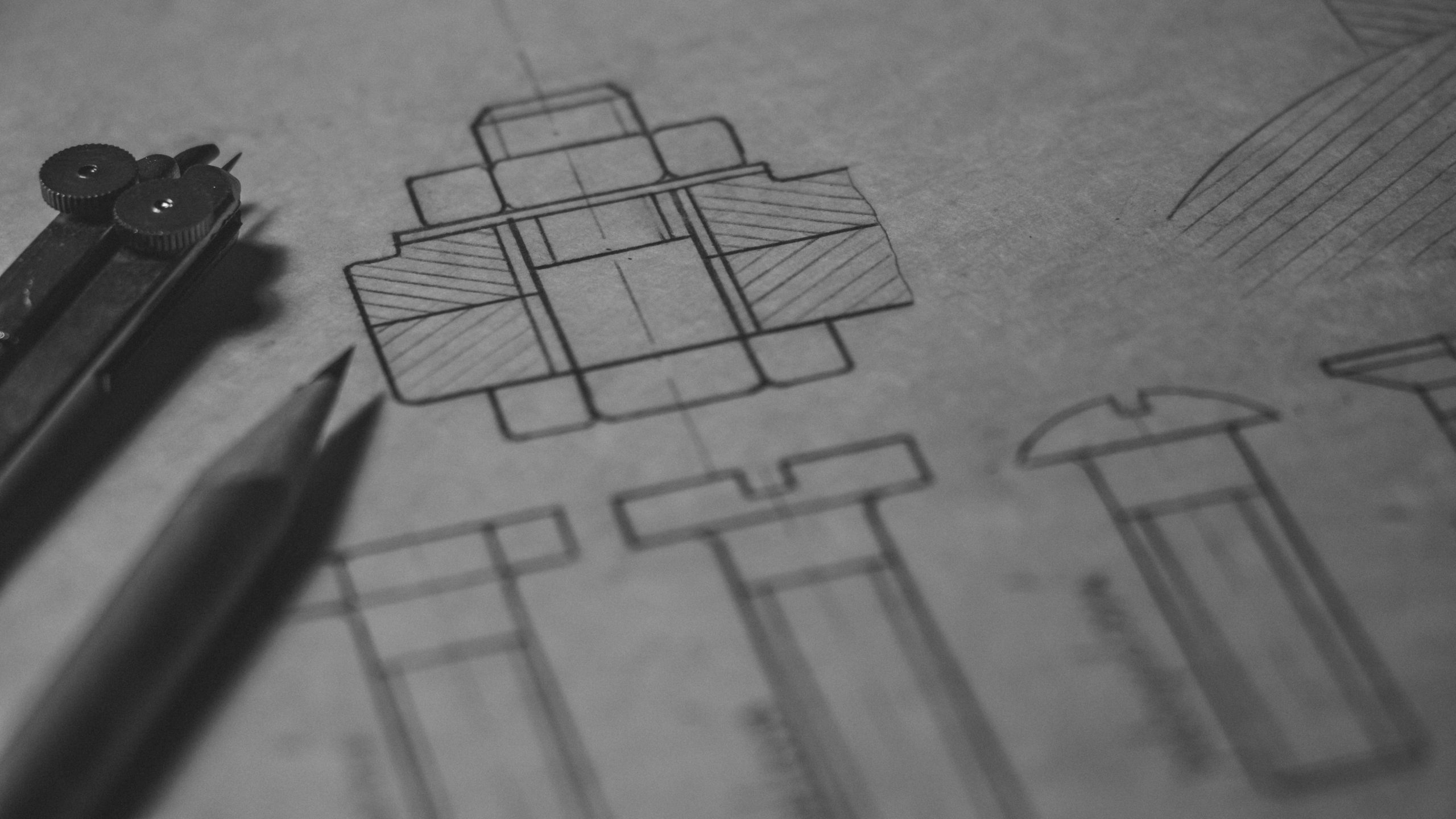

Our commitment revolves around providing superior subcontract machining, design, reverse engineering, and break-fix solutions to our esteemed clients. Leveraging the latest technological advancements and rigorous quality control, we craft bespoke parts of exceptional quality for our clients’ products.

Fully compliant with ISO 9001:2015 regulations, we consistently deliver superior quality products to thriving industries!

Our CNC Machine Tool Services

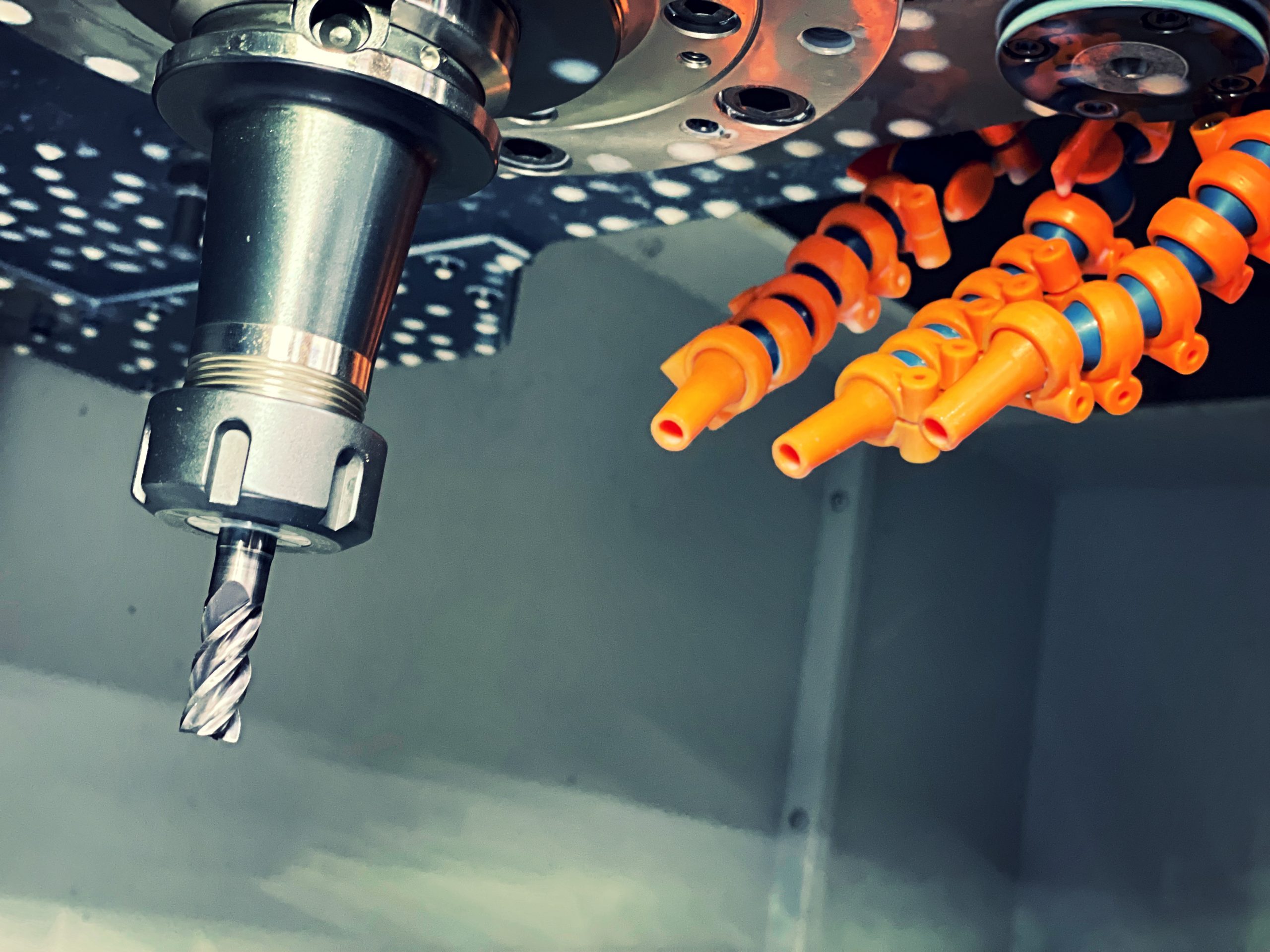

CNC Milling

CNC Milling uses a computer-controlled machine tool to craft accurate and intricate parts from a diverse array of materials like metals, plastics, and composites.

The workpiece gets snugly fastened to a worktable, and then the machine goes to work, removing material with a rotating cutting tool in line with the design specifications. This tool travels along multiple axes, conjuring up the shape and dimensions of the finished product with an impressive level of precision.

The tool can be programmed to groove through the x, y, and z axes, giving it the power to create complex shapes and features – holes, slots, pockets, and all the intricate contours.

What sets CNC Milling apart is its artful use of advanced software and automation, sculpting complex shapes with exceptional precision. These machines can be fitted with a wide array of cutting tools such as mills, drills, and taps.

The Types Of CNC Milling Machines

At Sotek Engineering, our arsenal boasts a diverse collection of CNC Milling Machines, each distinguished by its unique capabilities:

- Vertical Milling Machines: Employing a vertical spindle, these machines move with precision along the X and Y axes.

- Horizontal Milling Machines: Characterised by a horizontal spindle, these machines traverse the X and Z axes with lateral finesse.

- 5-Axis Milling Machines: Recognised for their versatility, these machines deftly navigate the cutting tool along five axes, enabling the creation of intricate and detailed parts.

- Gantry Milling Machines: These machines facilitate the movement of the cutting tool along multiple axes. This is achieved through a fixed bridge that spans the workpiece, enhancing precision and versatility in machining operations.

The Applications Of CNC Milling

CNC Milling Machines find application across a broad spectrum of manufacturing industries, owing to their remarkable precision standards and capability to yield high-quality products. These sectors encompass automotive, aerospace, medical, defence, and others.

The Benefits Of CNC Milling

CNC Milling brings a wide range of benefits to the manufacturing industry, such as:

- Efficient and fast production

- Reduced energy consumption

- Lower production cost

- Reduced defects

- Improved safety

- Quick assembly

- Minimal waste

- Precision

More Of Our CNC Machine Tool Services

CNC Turning

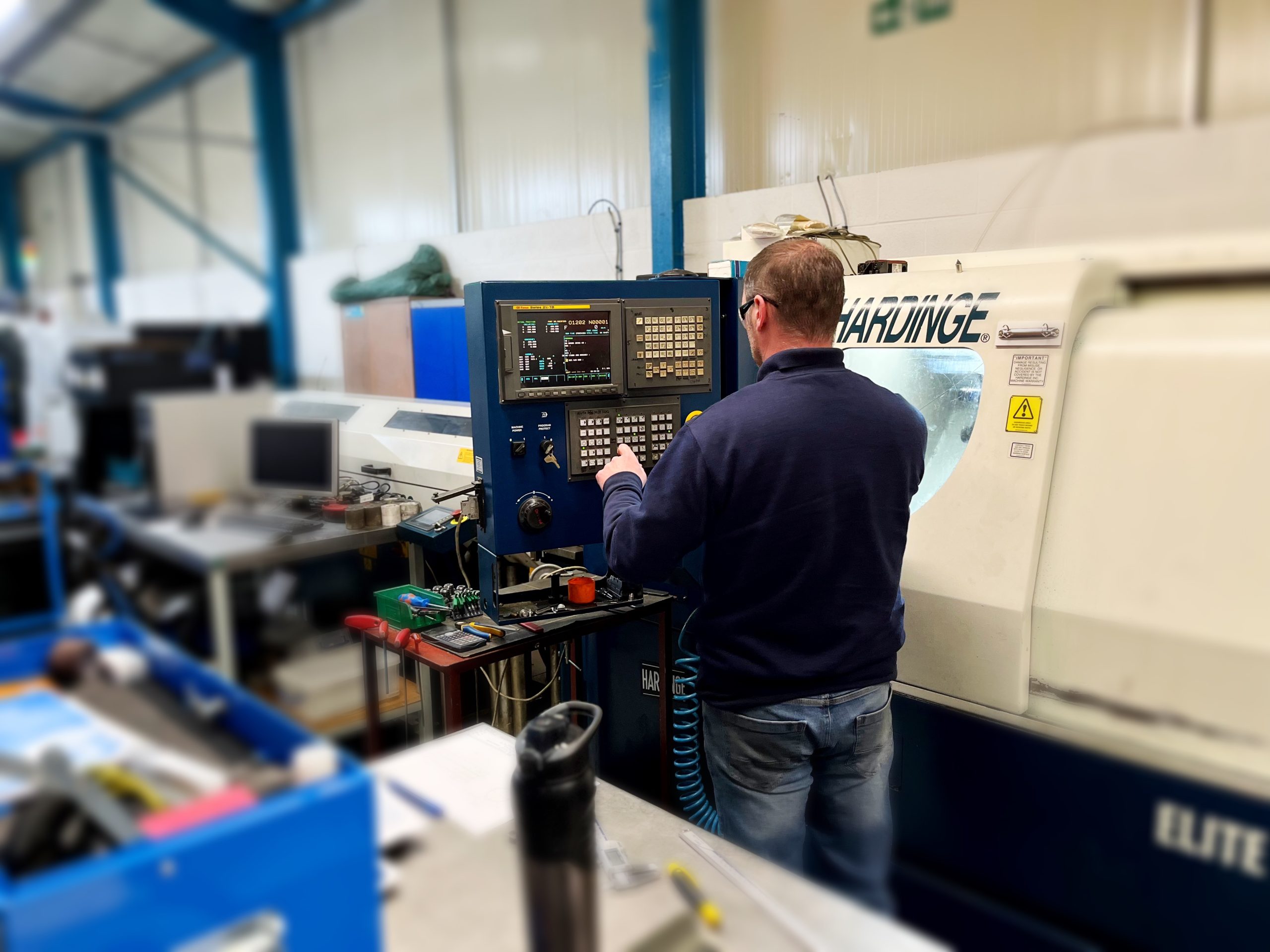

CNC Turning is a machining process wherein cylindrical or conical components are produced by the use of a computer-controlled lathe.

The operational sequence involves the rotation of the workpiece against a cutting tool, securely held within a tool turret or holder. The lathe orchestrates the movement of the cutting tool along the material’s surface, resulting in the creation of the specified shape and dimensions.

The lathe machine is multifunctional, carrying out a range of processes such as facing, drilling, threading, and grooving. Similar to CNC Milling, CNC Turning accommodates a diverse range of materials, including metals, plastics, and composites, facilitating the rapid and accurate generation of parts.

The Features Of CNC Turning Machines

- Bar Feeder: The bar feeder functions as an automated facilitator, adept at introducing raw materials such as metal bars or tubes into the CNC lathe machine for the production of elongated, cylindrical parts. Its versatility shines as it accommodates multiple raw materials, flawlessly integrating them into the machine as per requirements. This systematic approach significantly enhances efficiency by eliminating the need for manual loading.

- Driven Tooling: Driven tooling assumes a pivotal role in the CNC turning process, orchestrating the creation of intricate features on the workpiece, including holes and slots. This is achieved through the deployment of rotating cutting tools, powered by a motor. The synergy of these elements facilitates a spectrum of operations on the workpiece, encompassing drilling, tapping, and milling, thereby ensuring a comprehensive and efficient manufacturing process.

The Applications Of CNC Turning

CNC Turning Machines play a crucial role in various manufacturing industries such as automotive, aerospace, medical, and defence.

These machines come with features that bring numerous benefits to the manufacturing sector, like ramping up production efficiency, cutting down timescales, and trimming costs.

The Benefits Of CNC Turning

- Efficient and fast production

- Reduced energy consumption

- Lower production cost

- Reduced defects

- Improved safety

- Quick assembly

- Minimal waste

- Precision

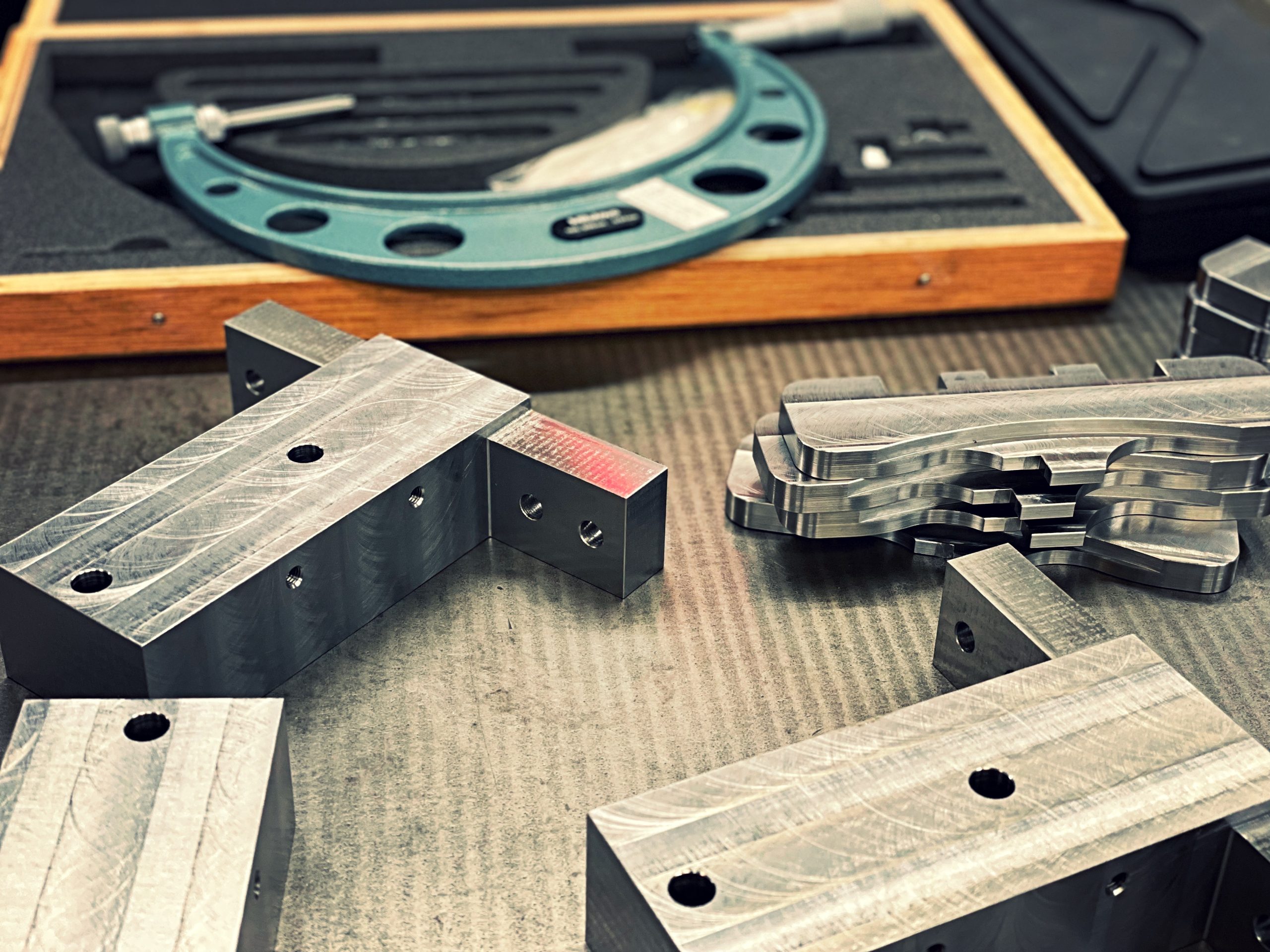

Industry-Leading Quality Control

At Sotek Engineering, we firmly believe that maintaining impeccable quality control standards is the key to achieving superior results. Our commitment revolves around integrating quality control principles into every facet of our work, a dedication that has earned us the trust of our valued customers.

Recognising that our client relationships are built on a foundation of confidence, we make customer satisfaction the focal point of our efforts. This strategic emphasis allows us to not only meet but consistently exceed expectations, ensuring the delivery of consistently high-quality results.

We employ ISO 9001:2015 compliant quality management systems, complemented by regular inspections and diligent statistical process control (SPC), to ensure that quality control remains a priority across all our operations. To learn more about our quality control practices, click here.

About Sotek Engineering

Founded in 2017 by Steve Brown and Oliver Cumbers, Sotek Engineering emerged with a clear vision: to provide consistently high-quality subcontract machining, design, reverse engineering, and break-fix solutions to businesses across the UK.

We take pride in serving as a trusted provider of CNC Turning services across a diverse array of industries. Our commitment to excellence is evident through the integration of cutting-edge technology, stringent quality control processes, and an unwavering dedication to exceptional customer service, resulting in an exemplary track record of delivering flawless products.

Located in Newton Abbot, just off the main arterial road connecting to the UK Motorway Network, our location ensures the facilitation of same-day or next-day deliveries as required.

At Sotek Engineering, our service spectrum encompasses a comprehensive range of CNC services, including:

- Reverse Engineering

- Re-Engineering

- CNC Routing

- CNC Milling

- Design

Why Choose Us?

Celebrating a legacy of 15 years in the industry, we take pride in having catered to hundreds of satisfied clients!

Our extensive industry background has empowered us to deliver superior quality products to our diverse clientele. The precision with which we produce flawlessly finished products has established us as a trusted supplier, particularly to companies demanding high standards of accuracy in the Medical, Aerospace, and Defence industries.

Thanks to our wealth of experience and unwavering dedication, we’ve consistently garnered glowing feedback from our valued customers. To read their testimonials, click here.

Contact Us If You’re Looking For CNC Machine Tool Services!

Let's get started with your next project...