Sotek Engineering

Aircraft CNC Machining

Looking For Top-Quality Aircraft CNC Machining?

Make Sure You Contact Us!

In the aircraft sector, precision, reliability, and compliance with stringent standards are paramount. Aircraft components must withstand extreme operating conditions and guarantee safety, performance, and durability.

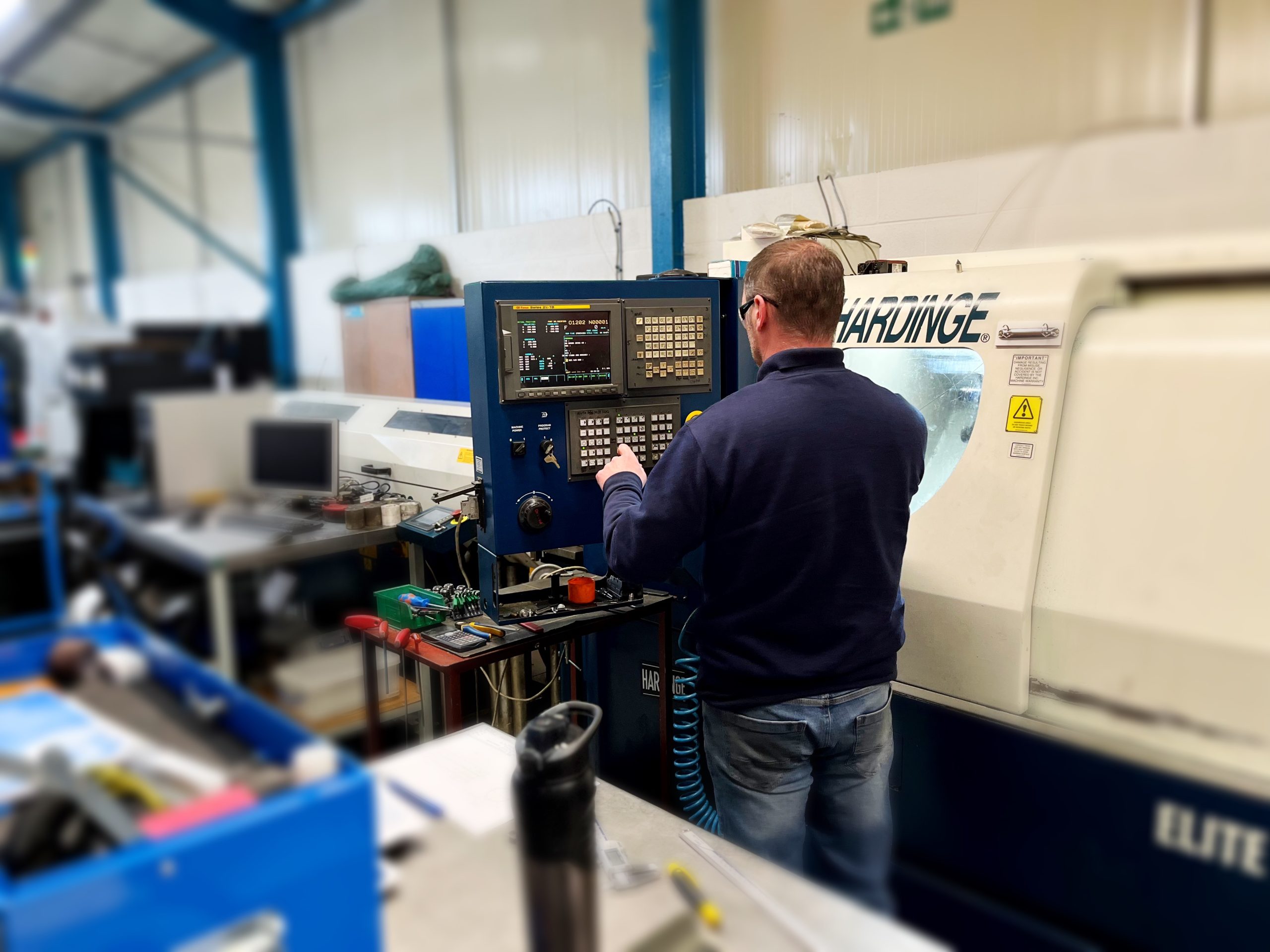

At Sotek Engineering, we specialise in delivering CNC machining services that meet the demanding requirements of the aircraft industry. We use advanced technologies, experienced engineers, and rigorous quality management systems to provide aircraft manufacturers with components of the highest calibre.

Based in Newton Abbot, Devon, Sotek Engineering is a trusted partner for manufacturers requiring precision-machined parts from prototype stage to full production runs. Our comprehensive service portfolio and commitment to excellence ensures we’re a preferred supplier for a wide range of blue-chip clients.

The Importance Of High-Quality Aircraft CNC Machining

The aircraft industry relies heavily on CNC machining due to its ability to consistently produce complex parts with exceptional precision and repeatability.

Components such as engine parts, structural brackets, hydraulic fittings, and avionics housings require micron-level accuracy and superior surface finishes—qualities that CNC machining delivers efficiently and effectively.

Manufacturing these components demands expertise in machining advanced materials including titanium, high-grade aluminium alloys, stainless steel, and speciality composites.

At Sotek Engineering, our team of engineers is fully equipped with the knowledge and experience essential for working with these materials, ensuring that all components meet the rigorous standards needed.

Our Extensive CNC Machining Capabilities For The Aircraft Sector

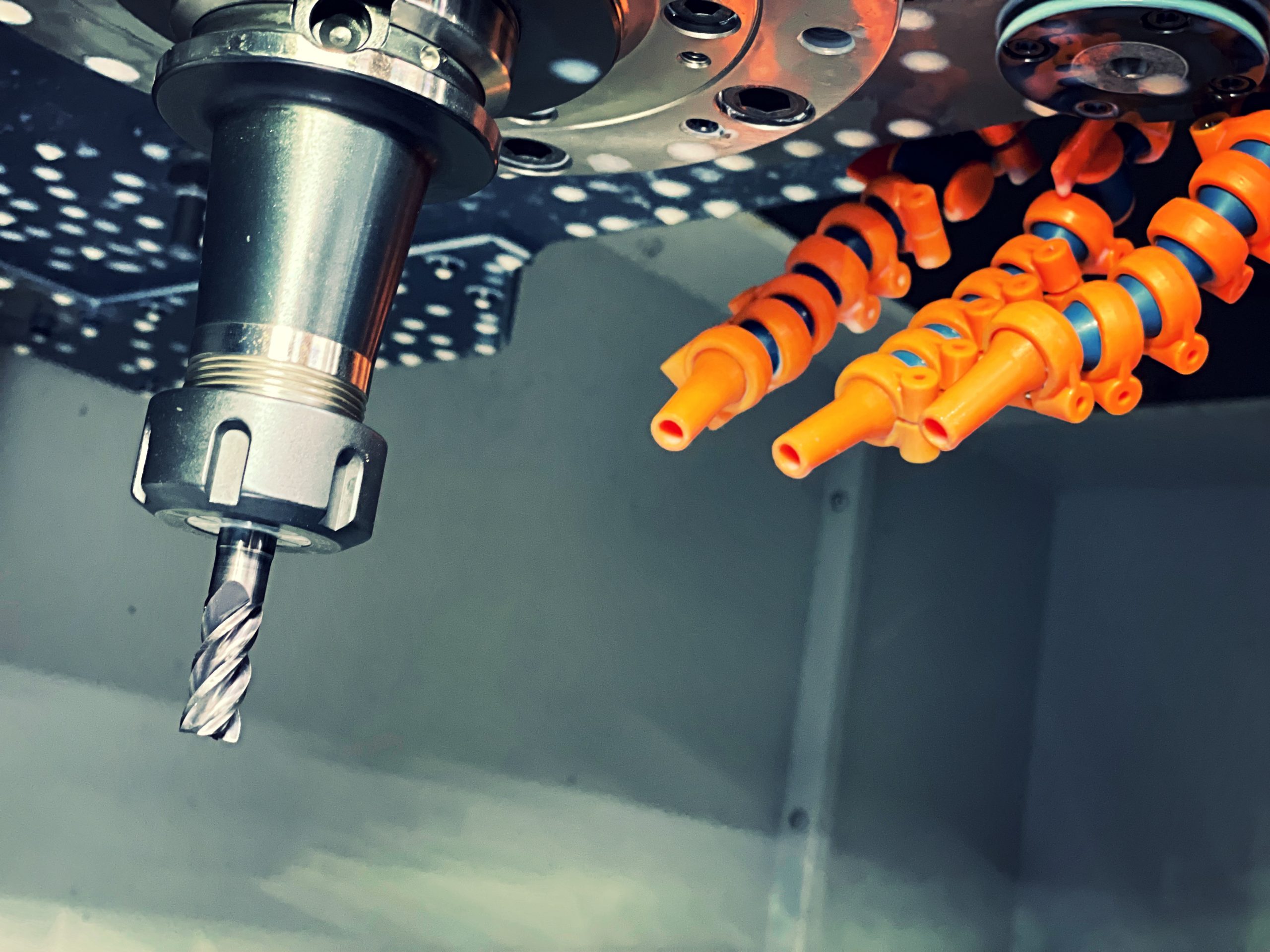

Advanced Multi-Axis Machining

At Sotek Engineering, we use state-of-the-art 5-axis CNC machining centres and multi-axis turning equipment for the production of highly complex geometries in a single setup. This reduces the potential for errors and improves lead times, while meeting the intricate design requirements common in aircraft applications.

Our multi-axis machining services are ideal for manufacturing aerofoil components, turbine blades, complex mounting assemblies, and structural elements where precision from multiple angles is crucial.

Precision Milling And Turning

Using a combination of vertical and horizontal milling machines alongside bar-fed CNC lathes with driven tooling, our CNC services offer the flexibility to manufacture both intricate milled parts and high-precision turned components.

This dual capability allows us to produce a broad spectrum of parts including shafts, fasteners, valve bodies, and more.

Material Expertise

Aircraft manufacturing frequently involves materials that are challenging to machine due to their hardness, toughness, or thermal properties.

That’s why we’ve ensured our engineering team possesses specialised knowledge in machining all the following materials:

Titanium Alloys: Valued for their strength-to-weight ratio and corrosion resistance in engine and structural components.

Stainless Steel: Utilised for its strength and corrosion resistance in hydraulic and structural fittings.

Composites And Advanced Polymers: Increasingly important for lightweight housing and fairings.

Aluminium Alloys: Widely used for airframe parts requiring lightweight yet durable materials.

Our machining processes are optimised to maintain material integrity while achieving the required surface finishes and dimensional tolerances.

From Prototype To Production

Whether your project involves a single prototype to validate a design, or a production run of hundreds of thousands of parts, Sotek Engineering provides scalable CNC machining services.

Our flexible manufacturing processes enable rapid turnaround on prototypes, coupled with the capability to ramp up for consistent volume production without compromising quality.

Quality Assurance And Traceability

As an ISO 9001:2015 certified organisation, Sotek Engineering maintains a robust quality management system aligned with aircraft industry expectations. Our quality control procedures include:

- Precision metrology using coordinate measuring machines (CMM)

- Statistical process control (SPC) for production consistency

- Full traceability of raw materials and machining processes

- Comprehensive in-process inspection protocols

These stringent quality assurance measures ensure each component delivered conforms to the highest aircraft standards, enabling you to meet certification and regulatory compliance demands.

Why Choose Sotek Engineering For Aircraft CNC Machining?

Deep Aircraft Expertise

Our engineers and machinists possess in-depth knowledge of aircraft manufacturing requirements, including familiarity with industry standards and specifications. This enables us to provide valuable input on design for manufacture, advise on material selection, and ensure components meet regulatory demands.

At Sotek Engineering, our team uses advanced CAD/CAM software tailored for aircraft applications, ensuring precise translation from digital designs to machined parts.

Flexible And Responsive Manufacturing

The dynamic nature of aircraft projects often requires adaptability and swift response times. Sotek Engineering’s modern facilities and lean manufacturing approach allow us to accommodate changing priorities, urgent orders, and design modifications with minimal disruption.

This agility supports manufacturers in meeting tight project schedules without sacrificing quality or delivery commitments.

Established Aircraft Supply Chain Partner

We have extensive experience serving aircraft clients across commercial aviation, defence, space technology, and UAV sectors.

This broad exposure enables us to understand diverse component requirements and deliver tailored machining solutions that align with client expectations and industry regulations.

Competitive Pricing Without Compromise

Through efficient machining strategies, material optimisation, and strong supplier relationships, we are proud to offer CNC machining solutions that provide excellent value for money.

Our cost-effective processes enable aircraft manufacturers to manage budgets effectively while maintaining uncompromised quality standards.

The Applications Of CNC Machining Services In Aircrafts

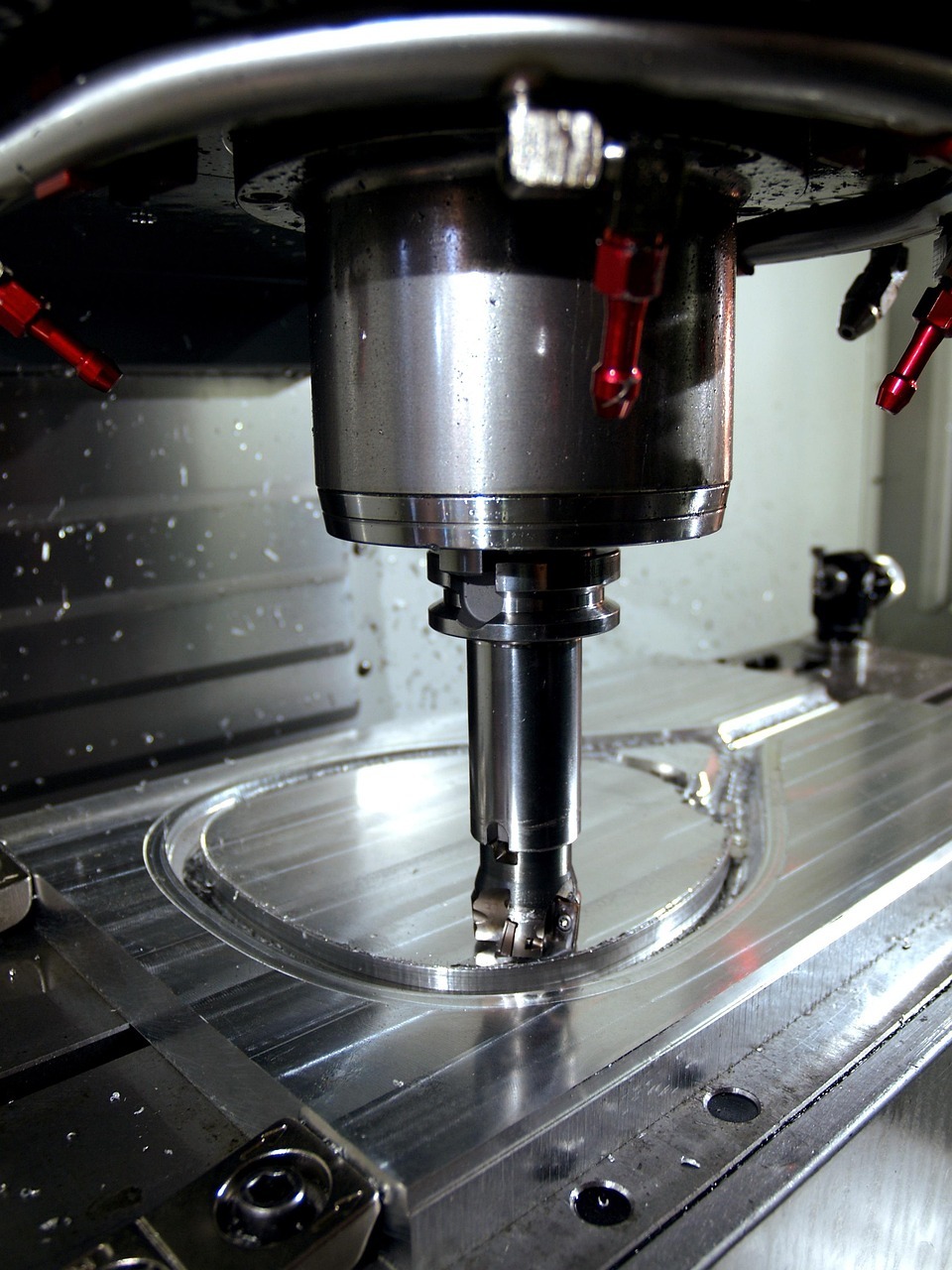

Engine And Turbine Components

Manufacturing precision-engineered parts such as turbine blades, compressor housings, and engine mounts requires expertise in machining high-strength alloys like titanium.

Our 5-axis machining centres produce these components with tight tolerances and surface finishes essential for high-performance operation under extreme conditions.

Structural And Airframe Components

At Sotek Engineering, we machine a variety of structural parts including brackets, reinforcements, and mounting assemblies.

These components require exceptional dimensional accuracy and finish quality to ensure integrity and seamless integration within the aircraft’s frame.

Hydraulic And Pneumatic Components

Our turning and milling capabilities extend to hydraulic spindles, valves, and connector bodies made from stainless steel or aluminium alloys.

These critical components must meet exacting standards for fit, function, and reliability.

Electrical And Avionics Housings

Machining lightweight housings for avionics and electronic systems from aluminium and composite materials is a specialised service offered by Sotek.

These parts demand tight tolerances and excellent finishes to protect sensitive equipment and maintain operational reliability.

Choose Sotek Engineering If You Need Aircraft CNC Machining!

We’re proud to be a trusted partner for companies in the aircraft industry who are seeking a top-quality CNC machining supplier.

Our combination of advanced technology, aircraft expertise, comprehensive quality systems, and responsive customer service ensures we consistently deliver components that meet the highest standards of precision and performance.

To discuss your aircraft CNC machining requirements or to request a quotation, contact our team of experts today!

Let's get started with your next project...