Sotek Engineering

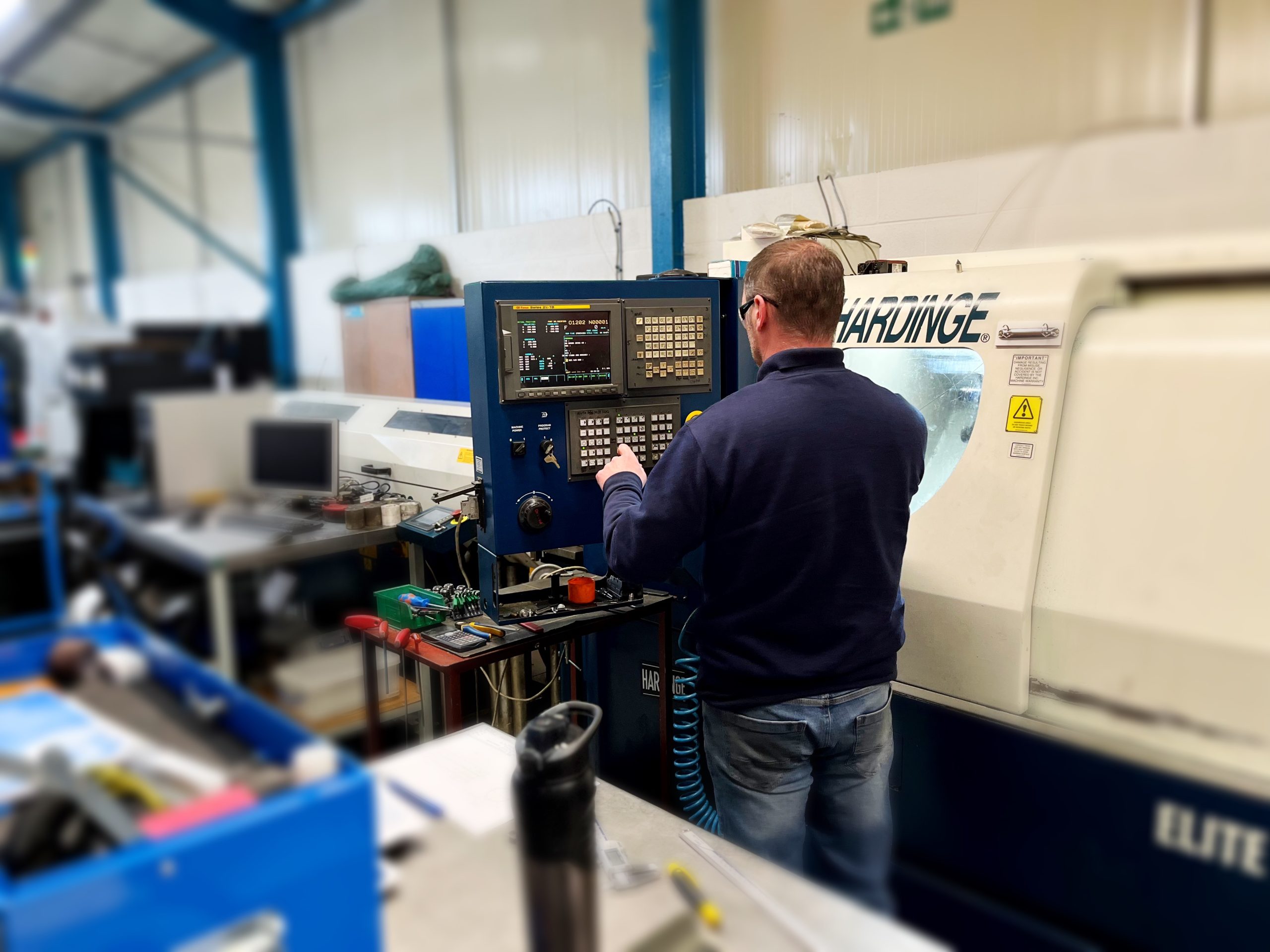

High Volume CNC Machining

Looking For Top-Quality High Volume CNC Machining?

Make Sure You Contact Us!

In modern manufacturing, the ability to produce parts consistently, at scale, and within tight tolerances is increasingly critical.

Whether you’re working in industries like automotive, aerospace, medical devices, or consumer electronics, high volume CNC machining is often essential for meeting the demands of both quality and quantity. At Sotek Engineering, we offer high-volume CNC machining solutions designed to address the specific needs of your industry, ensuring both efficiency and reliability throughout the entire process.

From the initial stages of design to the final production run, Sotek Engineering uses advanced technologies and a practical approach to ensure that your components are made to specification, on time, and within budget!

Understanding High Volume CNC Machining

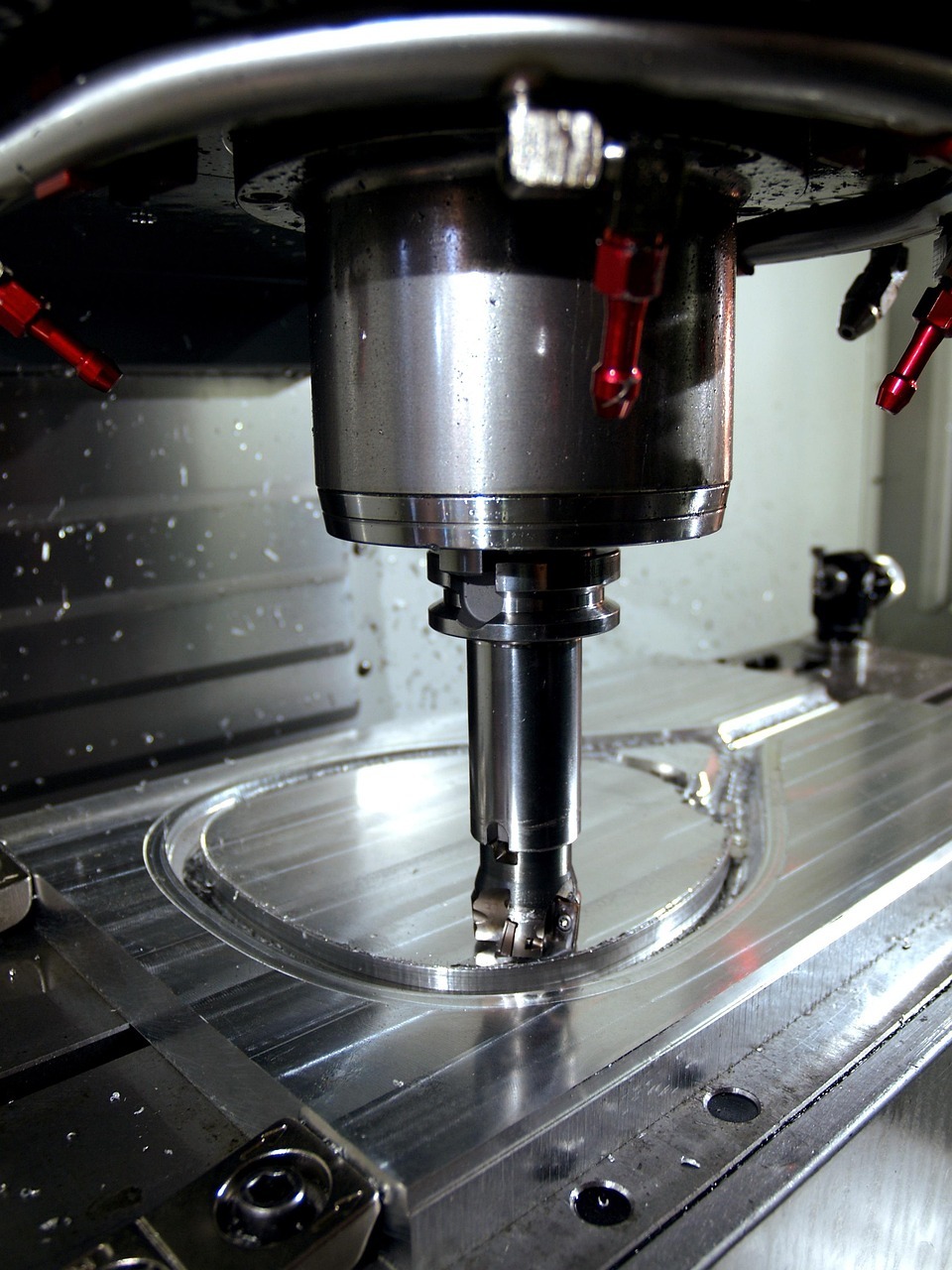

High-volume CNC machining refers to the process of manufacturing large quantities of parts with high precision using Computer Numerical Control (CNC) machines. These machines are guided by pre-programmed instructions to perform a variety of tasks, including drilling, milling, turning, and other complex operations. The primary advantage of CNC machining lies in its ability to deliver consistent results across large batches, ensuring each part is produced to exacting standards.

Unlike manual machining, CNC machining involves minimal human intervention once the program is set up, reducing the risk of error and improving consistency over the entire production run. This is especially important when dealing with large quantities of parts where even small discrepancies can accumulate and affect the final product.

At Sotek Engineering, we use CNC technology to handle a range of materials and geometries, providing you with a versatile solution to meet your production needs. Whether you’re manufacturing simple components or complex, multi-feature parts, CNC machining allows us to produce parts efficiently, at scale, while maintaining precision.

The Advantages Of High Volume CNC Machining

Consistency In Production

A primary benefit of CNC machining is its ability to produce parts with remarkable consistency. Each part is made according to the same pre-set parameters, so there’s no variation between units—ensuring every part in a high-volume run meets the same specification.

At Sotek Engineering, we guarantee this consistency through a combination of precise machine calibration, quality control procedures, and real-time monitoring. These measures help us maintain the level of precision needed, particularly when parts must meet the exacting standards required in industries like aerospace or medical device manufacturing.

Efficient Use Of Resources

High-volume production requires careful management of both materials and time. By optimising machine setup, material selection, and cutting strategies, we maximise material utilisation, minimising waste. This is not only more cost-effective but also aligns with sustainable practices, ensuring that scrap is reduced and recycled wherever possible.

We are careful to choose the right tools and processes to ensure that each part is manufactured using the least amount of material necessary while still meeting all strength, durability, and design requirements.

Faster Turnaround Times

Once set up, CNC machines can operate at high speeds with minimal human oversight. This makes high-volume production much faster compared to traditional methods. At Sotek Engineering, our advanced CNC machines are capable of running continuously, producing thousands of parts within a relatively short timeframe. This allows us to meet tight deadlines and scale production as needed, without compromising on the accuracy or quality of the final product.

Moreover, the integration of automation and real-time monitoring helps keep production on schedule, while also minimising the risk of delays typically associated with manual processes.

Reduced Labour Costs

Another benefit of high-volume CNC machining is the reduced need for manual labour. Once programmed and set up, CNC machines can run with minimal human intervention, reducing the reliance on skilled operators during production. This not only decreases overall production costs but also eliminates human errors that could otherwise affect the quality of the parts.

At Sotek Engineering, our team focuses on overseeing the machinery and ensuring that operations run smoothly, leaving our skilled machinists and engineers to handle more complex tasks such as quality control, troubleshooting, and fine-tuning processes as needed.

Addressing Challenges In High-Volume CNC Machining

While high-volume CNC machining offers numerous advantages, it also presents challenges that need to be carefully managed to ensure a successful production run.

Below are some of these challenges and the details of how our team addresses them to ensure high-quality outcomes every time.

Tooling And Setup Costs

High-volume CNC machining typically involves significant upfront investment in tooling and setup. However, the cost per unit decreases significantly as the volume increases. To mitigate the initial setup costs, Sotek Engineering works with advanced CAD/CAM software to streamline the design and setup process. This reduces both the time and cost associated with creating custom tooling for each part.

Our engineers take a collaborative approach when planning tooling, ensuring that setups are as efficient as possible and that tooling is optimised for long runs. This careful preparation helps to avoid any unnecessary delays and ensures that parts are made to specification from the first cycle.

Material Selection And Waste Minimisation

High-volume machining often involves large quantities of raw material, and efficiently managing material usage is essential to keeping costs down.

At Sotek Engineering, we carefully choose materials based on both their suitability for the design and their cost-effectiveness. We work closely with our clients to understand the specific requirements of each project and optimise material selection to balance strength, durability, and cost. Additionally, we implement cutting strategies that maximise material yield, which helps reduce waste and associated costs.

Complex Geometries And Tight Tolerances

One of the defining features of high-volume CNC machining is its ability to handle complex part geometries with tight tolerances. However, as production runs scale up, it becomes more challenging to maintain these standards across every part.

To manage this, we use high-precision CNC machines capable of handling complex features and tight tolerances across a range of materials. We implement stringent quality control measures, including regular in-process inspections and final checks, to ensure that every part remains within specification. This helps mitigate any deviations that could affect the functionality or performance of the parts.

We also leverage advanced multi-axis machining and other techniques that allow us to create intricate shapes and multi-feature parts without compromising on the efficiency of the production process.

Why Choose Us For High-Volume CNC Machining?

When it comes to high-volume CNC machining, there are several key factors to consider: precision, speed, cost, and reliability. At Sotek Engineering, we bring together all these elements to provide a comprehensive solution for your manufacturing needs.

Our team of skilled engineers and machinists has extensive experience handling complex projects in high-volume production. Whether you need to produce a few hundred parts or several thousand, we have the capacity and expertise to meet your needs.

We invest in the latest CNC technology and maintain a close focus on process optimisation to ensure that each project is completed efficiently, without compromising quality. Our commitment to maintaining high standards of precision, while reducing waste and improving overall efficiency, ensures that we can deliver your parts on time and within budget.

At Sotek Engineering, we’re dedicated to providing cost-effective, high-quality manufacturing solutions that meet the challenges of modern production. Our team works closely with clients throughout the production process to ensure that all requirements are met, from initial design to final delivery.

Contact Us If You Need Top-Quality High-Volume CNC Machining!

Let's get started with your next project...