Sotek Engineering

CNC Aluminium Machining

Need Top-Quality Aluminium CNC Machining?

Make Sure You Contact Us!

At Sotek Engineering, we pride ourselves on delivering exceptional aluminium CNC machining services that meet the demanding standards of modern manufacturing. As specialists in computer numerical control machining, we combine cutting-edge technology with extensive engineering expertise to produce aluminium components of unrivalled precision and quality.

Our commitment to excellence is reflected in every aspect of our operation, from our investment in the latest CNC machinery to our team of highly skilled technicians. We understand that in sectors such as aerospace, automotive, medical technology, and electronics, there is absolutely no margin for error when it comes to component manufacturing. That’s why we’ve implemented rigorous quality control measures throughout our production process, backed by our ISO 9001:2015 certification.

What truly sets us apart is our ability to handle projects of any scale while maintaining consistent quality standards. Whether you require a single prototype or a production run of thousands, our CNC machining services deliver identical precision across every component. This repeatability, combined with our efficient production methods, ensures you receive parts that not only meet but exceed your expectations in terms of accuracy, performance, and value.

What Is Aluminium CNC Machining?

Computer Numerical Control (CNC) machining represents the gold standard in modern aluminium machining. This advanced manufacturing process uses pre-programmed computer software to control the movement of factory tools and machinery with extraordinary precision. Unlike traditional manual machining, CNC technology allows for three-dimensional cutting tasks to be completed in a single set of commands with micron-level accuracy.

The process begins with detailed computer-aided design (CAD) models that specify every dimension and feature of the required component. These digital blueprints are then converted into machine instructions through computer-aided manufacturing (CAM) software. Our sophisticated CNC machines interpret these instructions to guide cutting tools with exceptional precision, removing material from aluminium billets or sheets to create components that match the digital design perfectly.

One of the most significant advantages of CNC aluminium machining is its ability to maintain consistent quality across production runs. Once a machining program has been perfected, it can produce identical components with minimal variation – a crucial factor for industries where component interchangeability is essential. This repeatability, combined with the technology’s capacity for creating complex geometries, makes CNC machining the preferred manufacturing method for precision aluminium components in many industries.

How Is CNC Aluminium Machining Used?

Aluminium possesses several material properties that make it particularly well-suited for CNC machining processes. Its excellent machinability allows for high-speed cutting operations while maintaining superior surface finishes, and its impressive strength-to-weight ratio makes it invaluable for applications where reducing mass is critical. Our CNC technology is specifically optimised to take full advantage of these characteristics, producing components that meet even the most demanding specifications.

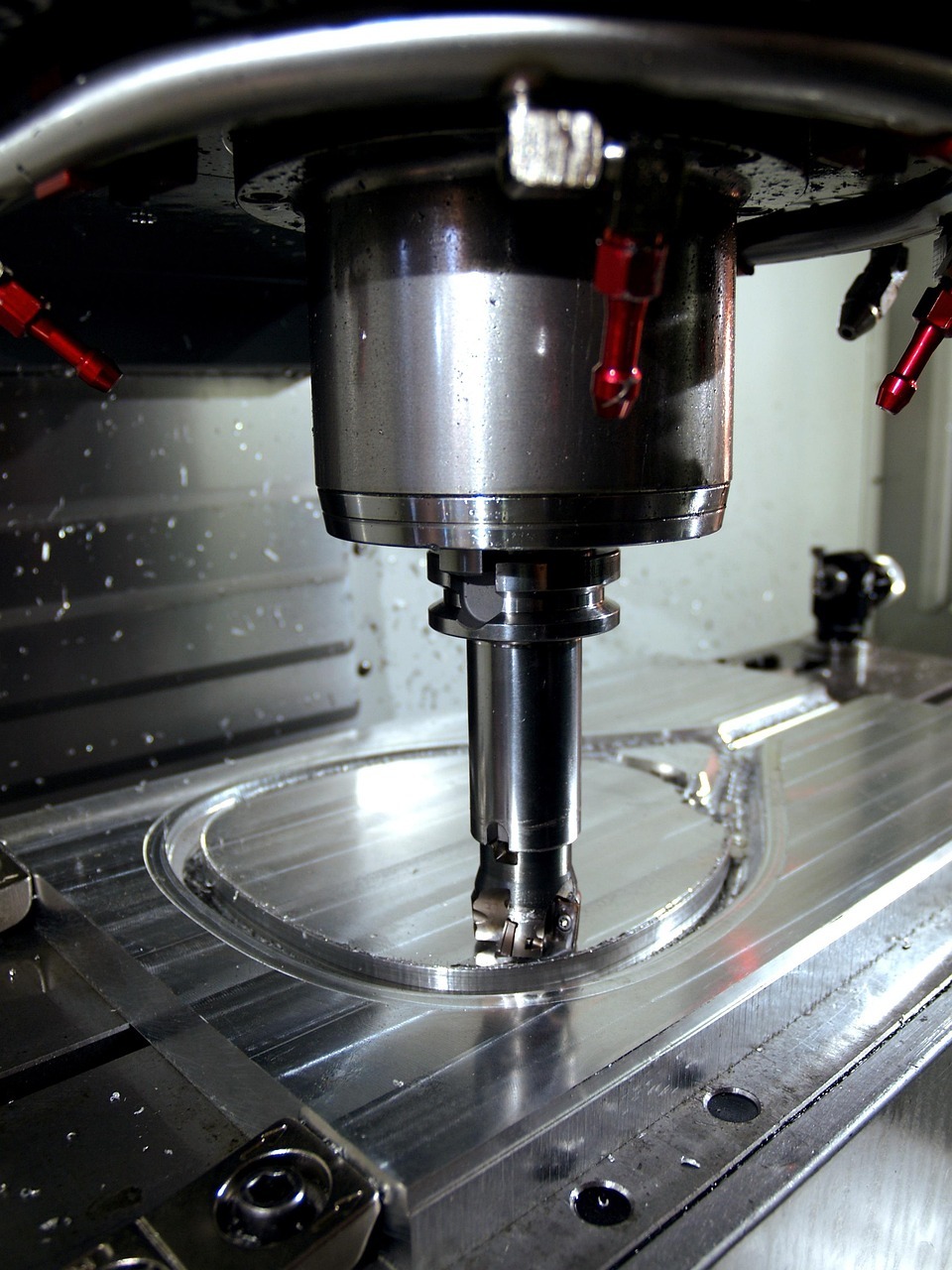

The precision achievable through CNC machining is truly remarkable. We routinely maintain tolerances within ±0.05mm, with even tighter specifications possible for critical applications. This level of accuracy ensures perfect fit and function in assemblies, significantly reducing the need for secondary operations or adjustments. The process excels at creating complex features such as thin walls, deep cavities, and intricate contours that would be challenging or impossible to achieve with conventional machining methods.

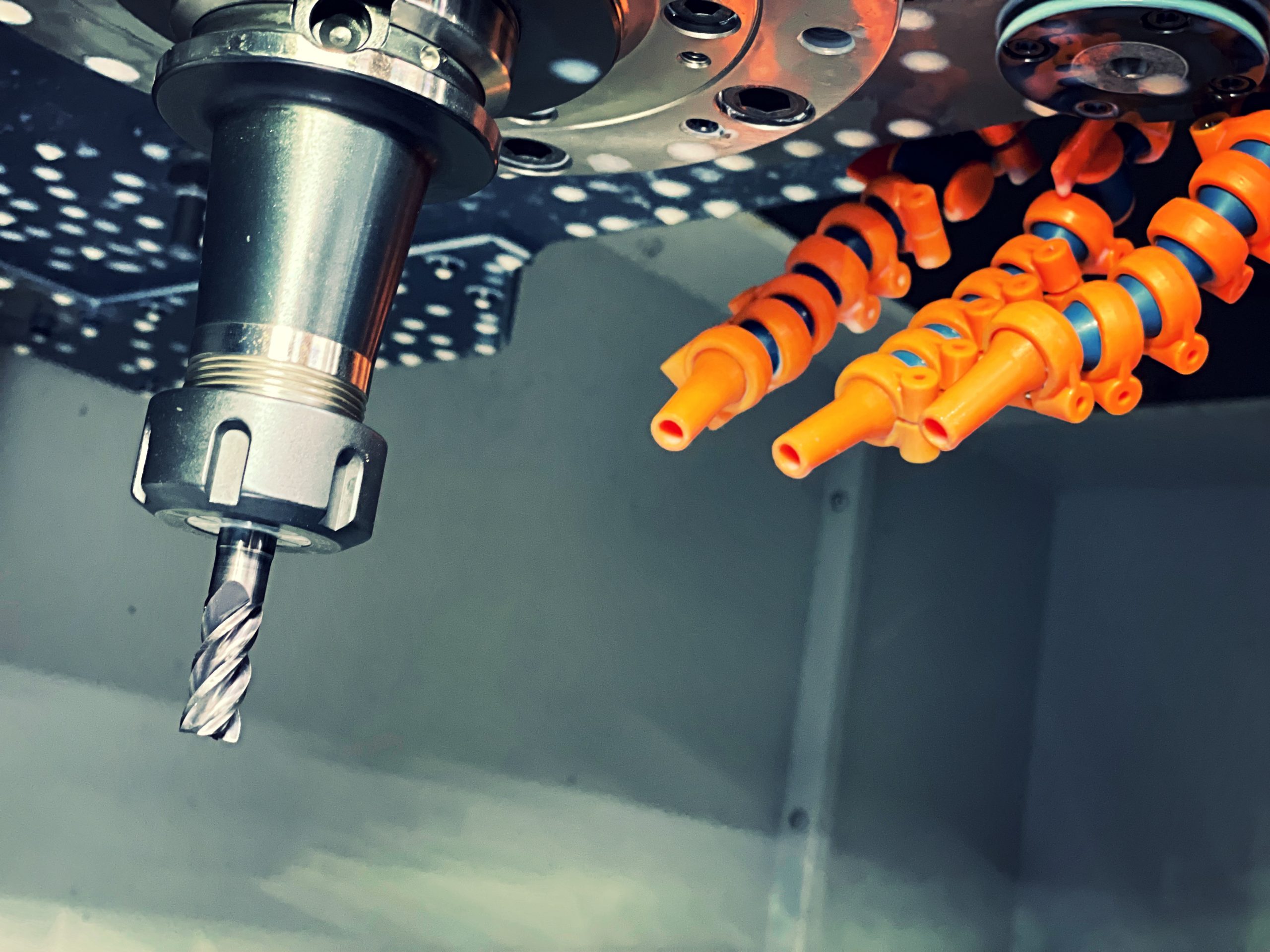

From an operational perspective, CNC machining offers substantial efficiency benefits. Automated tool changing and continuous operation capabilities allow for uninterrupted production, while advanced software optimises tool paths to minimise machining time. These efficiencies translate to shorter lead times and reduced production costs, particularly for medium to large batch sizes where the initial programming investment can be spread across multiple components. The technology also minimises material waste through optimised machining strategies.

Our Services

CNC Milling For Aluminum

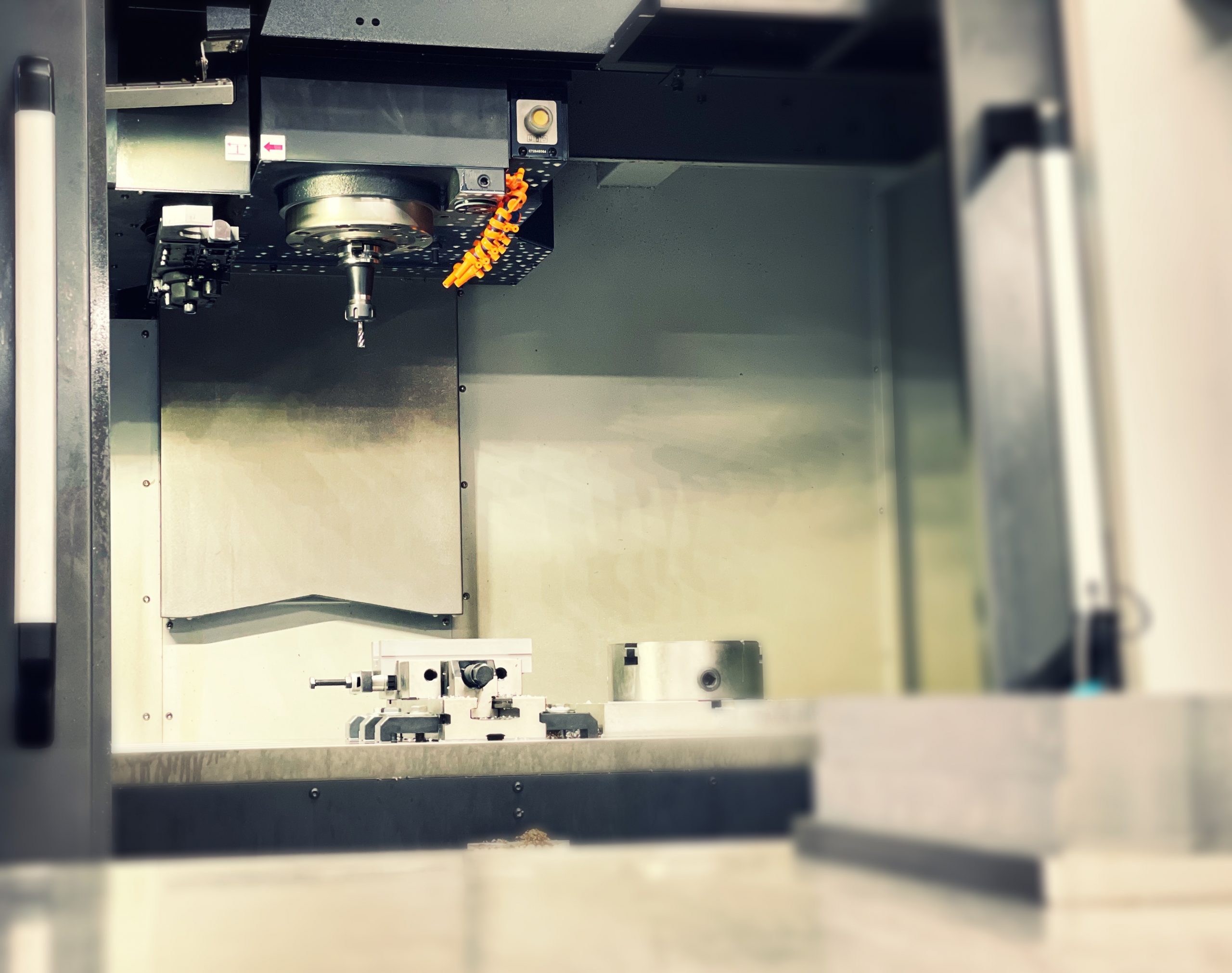

Our CNC milling services utilise advanced multi-axis machining centres to produce complex aluminium components with exceptional dimensional accuracy. The milling process is particularly effective for creating three-dimensional shapes, precision slots, and intricate surface features. We operate both vertical and horizontal machining centres to accommodate components of varying sizes and complexities, ensuring we have the right equipment for every project.

The flexibility of our milling capabilities allows us to work with all grades of machinable aluminium, from commonly used 6061 and 6082 alloys to high-strength options like 7075. Our experienced machinists select optimal cutting tools and parameters for each specific material to ensure clean cuts, minimise tool wear, and achieve the required surface finish. For components demanding particularly fine finishes, we can implement secondary operations including polishing, anodising, or powder coating to meet exact specifications.

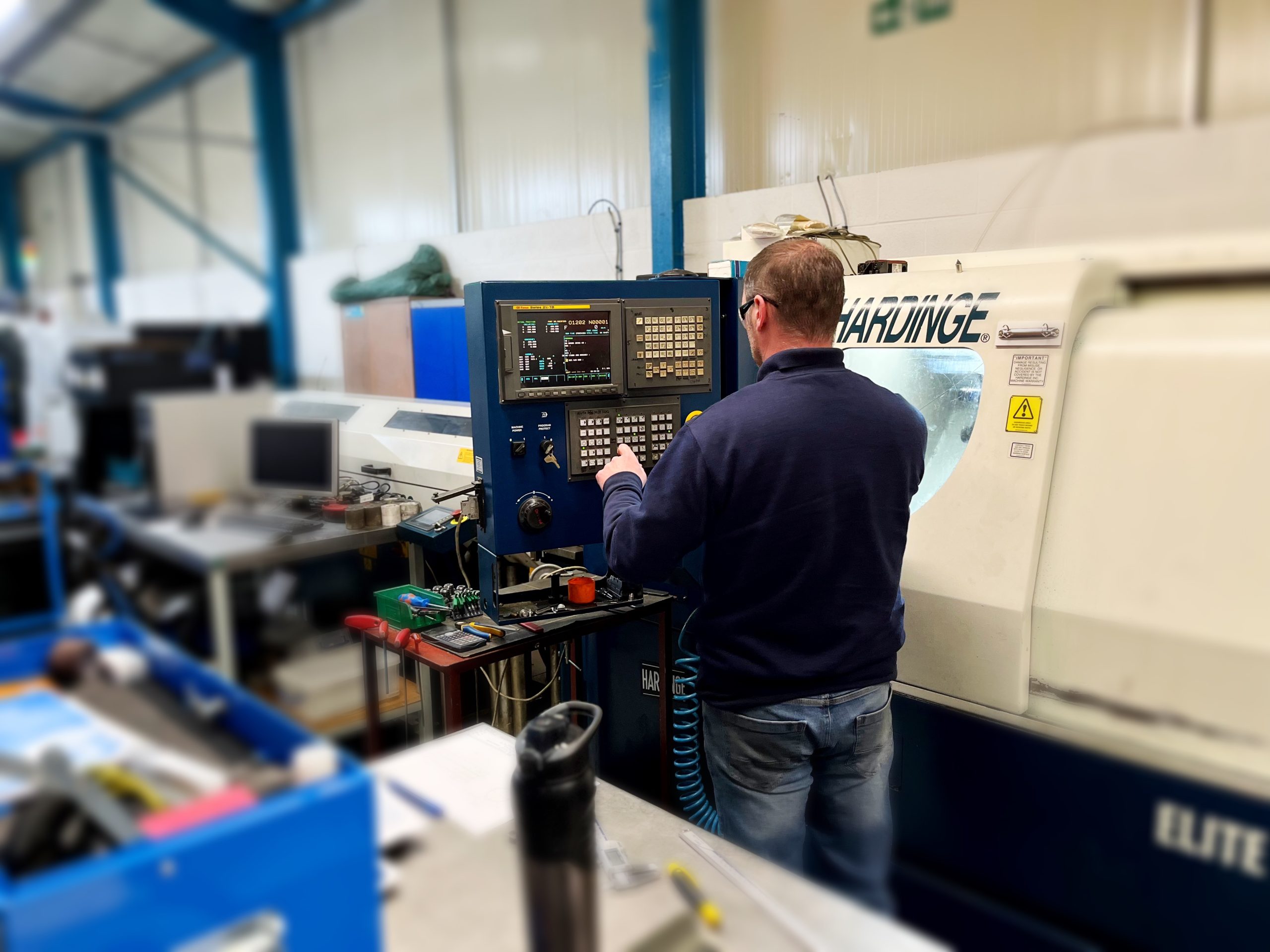

CNC Turning For Aluminium

For rotational components, our CNC turning services deliver unrivalled precision and production efficiency. Using modern turning centres with live tooling capabilities, we can produce complex cylindrical parts in a single setup. This approach reduces handling time and improves concentricity between features, resulting in higher-quality components with better dimensional consistency.

Our turning capabilities extend far beyond simple cylindrical shapes. With subspindle and Y-axis functionality, we can machine complex geometries including off-centre features, cross holes, and intricate end details. This makes our turning services suitable for an extensive range of aluminium components, from simple bushings to sophisticated hydraulic system parts. The process is particularly efficient for high-volume production, where the rapid cycle times of CNC turning provide significant cost advantages without compromising on quality.

Custom Aluminum Part Manufacturing

Beyond standard milling and turning, we offer custom manufacturing solutions for aluminium components. Our engineering team works collaboratively with clients to optimise designs for manufacturability, suggesting modifications that can enhance performance or reduce production costs without compromising functionality.

This partnership approach extends from the initial concept through to final production. We provide comprehensive support with material selection, design refinement, prototyping, and full-scale manufacturing, ensuring a seamless transition between development stages. For clients requiring specialised finishes or treatments, we coordinate with trusted partners to deliver components that are ready for immediate use in their intended applications. Our expertise in design for manufacture (DFM) helps identify potential production challenges early in the process, saving both time and costs.

Why Choose Sotek Engineering For Your Aluminium CNC Machining Needs?

Selecting Sotek Engineering as your aluminium machining partner provides access to expertise and technology that delivers consistent, high-quality results, while our ISO 9001:2015 certification demonstrates our commitment to quality management at every stage of production. We maintain these standards through regular equipment calibration, comprehensive staff training, and robust quality assurance procedures that leave nothing to chance.

Our substantial investment in advanced CNC equipment ensures we can handle projects of any complexity. From high-speed machining centres capable of producing intricate components quickly to multi-axis machines that complete complex parts in single setups, our technology portfolio is specifically designed to meet diverse manufacturing challenges. This technical capability is supported by a team of skilled machinists and engineers who bring decades of collective experience to every project, ensuring optimal results regardless of complexity.

We fully appreciate that timely delivery is often as critical as quality in manufacturing. That’s why our production planning and shop floor management systems are meticulously designed to optimise workflow and minimise lead times without ever compromising on precision. And for urgent requirements, we offer expedited services that can accelerate production while maintaining our uncompromising quality standards.

The Industries We Serve

The combination of aluminium’s material properties and our precision machining capabilities makes our services invaluable across numerous sectors. For instance, in the automotive industry, we produce lightweight components that contribute to improved fuel efficiency without sacrificing strength or durability. These include engine parts, transmission components, and structural elements that benefit from aluminium’s excellent strength-to-weight characteristics.

Aerospace applications demand even higher levels of precision and reliability. Our machining processes meet the stringent requirements of this sector, producing components for airframes, avionics, and propulsion systems. We fully understand the critical nature of aerospace components and maintain rigorous quality control procedures to ensure every part meets exacting standards for dimensional accuracy and material integrity.

The medical device industry relies on our capabilities for precision instruments and equipment components. Aluminium’s biocompatibility and our ability to machine it to medical-grade tolerances make it an ideal choice for many healthcare applications. We adhere to cleanroom protocols when required and can provide comprehensive documentation necessary for medical device validation and traceability.

Electronics manufacturers benefit from our ability to produce intricate enclosures, heat sinks, and mounting components that facilitate thermal management in high-performance systems. The electrical and thermal conductivity of aluminium, combined with our precision machining capabilities, creates ideal solutions for challenging electronic packaging requirements where both performance and reliability are paramount.

Get In Touch!

Whether you have fully developed designs ready for production or need assistance turning a concept into a manufacturable component, our team are ready to help. We welcome the opportunity to discuss your aluminium machining requirements and develop solutions that meet your technical specifications and budget considerations.

Contact us today to speak with one of our engineering specialists about your project. We’ll provide expert guidance on material selection, design optimisation and production planning to ensure you receive components that perfectly match your requirements. With our combination of advanced technology, skilled personnel and unwavering commitment to quality, we know our aluminium CNC machining solutions will exceed your expectations.

Contact Us If You’re Looking For Top-Quality CNC Aluminium Machining!

Let's get started with your next project...