Sotek Engineering

Manufacturing Outsourcing Services

Looking For Top-Quality Manufacturing Outsourcing Services?

Contact Us!

At Sotek Engineering, we’re passionate about precision. We offer expert manufacturing outsourcing services designed to help businesses and entrepreneurs bring their designs to life with expert CNC milling, CNC turning, and design for manufacturing.

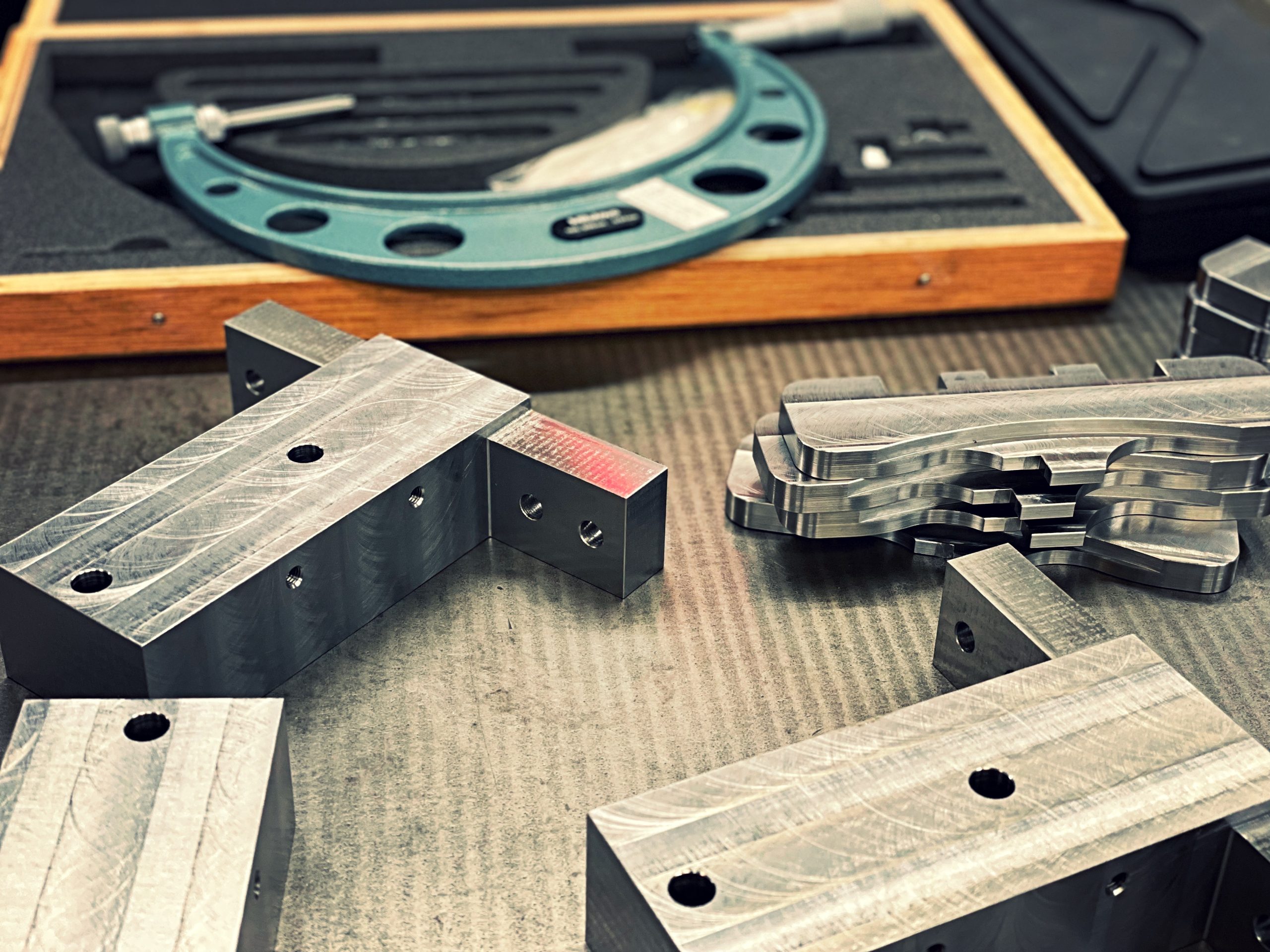

Quality is at the heart of everything we do; we follow ISO 9001-2015 standards, conduct thorough inspections, and use statistical process control (SPC) to ensure every part meets the highest level of accuracy and reliability.

Over the years, we’ve built a strong reputation as a trusted provider across industries like Medical, Automotive & Motorsport, Aerospace & Defence, Oil & Gas, and Nuclear, with our devotion to high quality being key. With an ISO 9001-2015 certification and a commitment to excellence, we’re here to deliver reliable, high-precision results time after time!

What Is CNC Machining?

CNC machining is a highly versatile manufacturing process used to create exact components from materials such as acrylics, metals, plastics, and wood.

This subtractive process involves cutting away material from a solid workpiece using computer-controlled machinery, ensuring exceptional accuracy and detail.

Thanks to its precision and efficiency, CNC machining is widely used across many vital industries.

The Two Types Of CNC Machining

The two primary CNC machining methods are CNC Turning and CNC Milling:

CNC Turning:

This method involves a rotating CNC lathe that holds the workpiece while a cutting tool gradually removes material to achieve the desired cylindrical or conical shape. It’s the go-to choice for manufacturing the precise, cylindrical components used in various applications.

CNC Milling:

Ideal for mass production, this process uses a rotating cutting tool that carves away material from a fixed workpiece. With the ability to move along multiple axes, CNC milling can create intricate features such as holes, slots, and complex contours with high precision.

Both CNC milling and turning offer exceptional accuracy, making them essential techniques in modern manufacturing.

The Advantages Of CNC Machining

CNC machining offers precision, reliability, and versatility, making it a go-to manufacturing method across industries. Here’s why it stands out:

Perfect For Complex Designs:

With its ability to move along multiple axes, CNC machining can produce intricate, highly detailed components that other methods simply can’t match.

Incredible Accuracy:

Unlike plastic injection moulding or 3D printing, CNC machining delivers unrivalled precision, ensuring every part is made to exact specifications. This is especially important for prototyping and mass production.

Works With A Variety Of Plastics:

CNC machining is compatible with many plastic polymers, including Teflon (PTFE), Delrin (POM), Acrylic, Nylon, UHMW, and Polyether (PEEK) – making it ideal for plastic product manufacturing.

Tight Tolerances:

CNC machining can achieve tolerances far beyond what injection moulding or 3D printing can offer, guaranteeing a high level of precision.

Fewer Defects, Better Quality:

With CNC machining, the level of precision leads to fewer defects and a higher level of consistency and quality.

Ultimate Flexibility:

Whether you need simple or complex parts, CNC machining can handle a wide range of shapes and designs, making it one of the most versatile manufacturing methods available.

Less Waste, More Savings:

Precision cutting means less material waste, helping manufacturers save on costs while being more environmentally friendly.

Our Commitment To Providing Quality Manufacturing Outsourcing Services

At Sotek Engineering, we’re committed to delivering top-quality results at competitive prices. Precision and reliability are at the heart of everything we do, and we uphold the highest standards through ISO 9001-2015 compliant systems, regular inspections, and strict quality control.

Our customers always come first. We believe in exceptional service, expert guidance, and building lasting relationships with every client we work with. From Aerospace & Defence to Oil, Gas, and Nuclear; from Automotive and Motorsport to Medical, we proudly serve industries that demand nothing but the best!

About Us

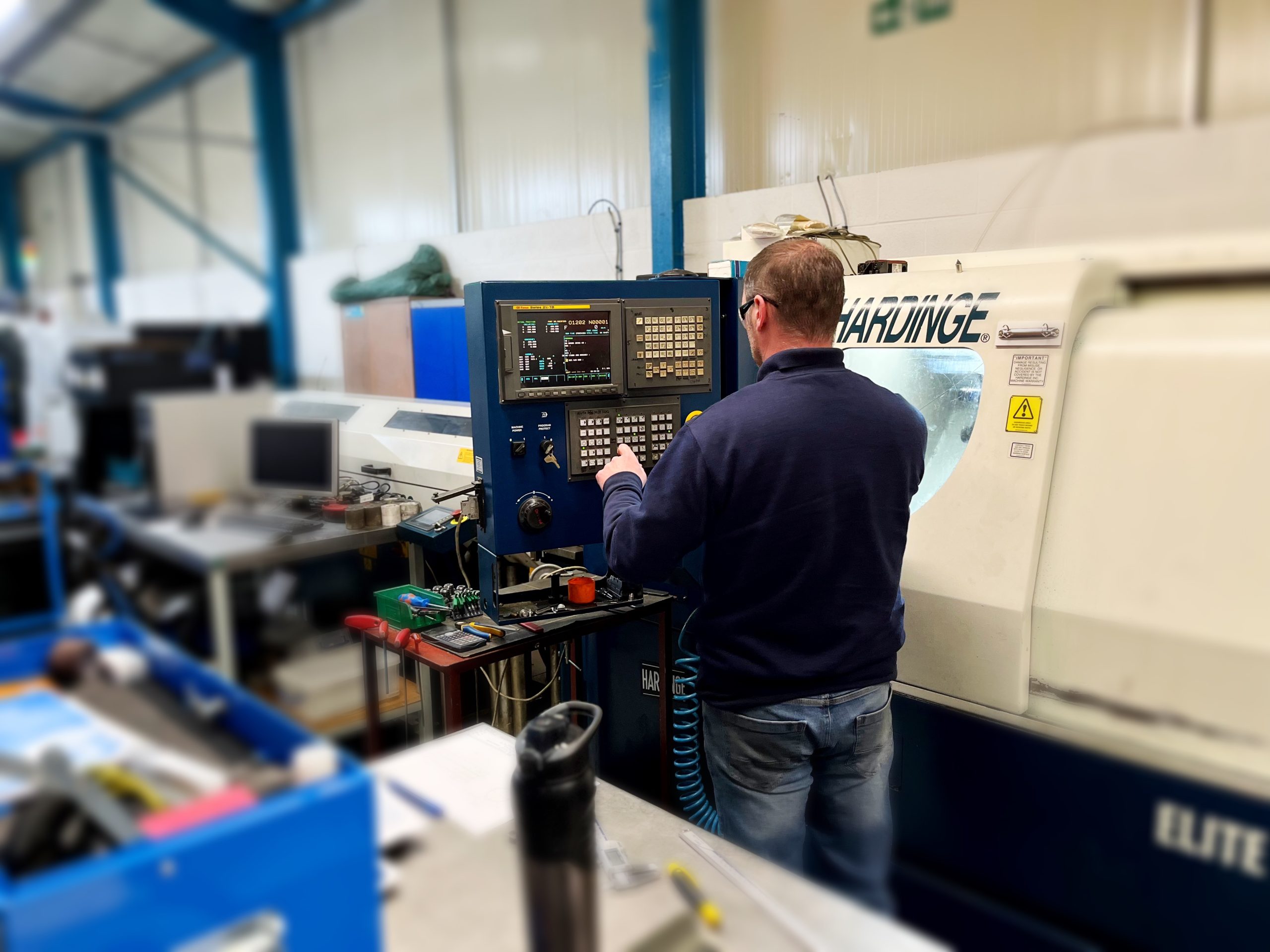

Founded in 2017 by Oliver Cumbers and Steve Brown, Sotek Engineering was built on a clear mission: to provide high-quality design, machining, reverse engineering, and break-fix solutions to UK businesses.

With a team of experienced professionals and state-of-the-art CNC technology, we combine precision with strict quality control to ensure exceptional results every time!

Located in Newton Abbot, right off the main arterial road connecting to the UK Motorway Network, we offer fast and reliable deliveries – often within the same day or next day – because we know that time is crucial to our clients.

Our contract CNC services include:

- Re-Engineering & Modifications

- CNC Routing

- CNC Machining

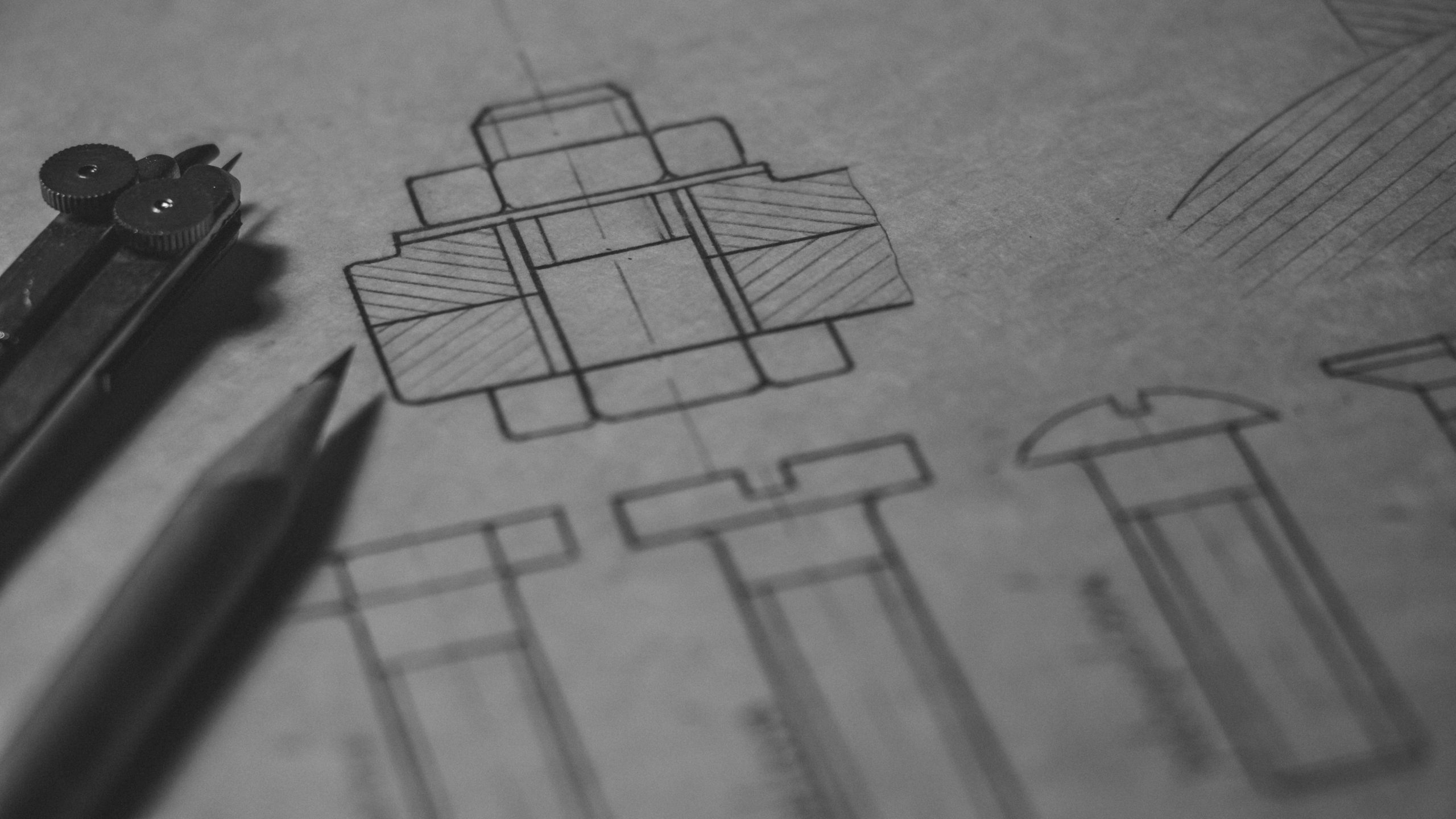

- Design & Prototyping

- Reverse Engineering

At Sotek Engineering, we’re here to keep your business moving with precision, efficiency, and unmatched expertise.

Our Testimonials

With over 15 years of experience in the manufacturing industry, we’ve mastered the art of delivering precision-engineered CNC machined products with flawless finishes.

Our proficiency in the creation of flawlessly finished CNC machined products has made us a trusted supplier to blue-chip clients in diverse industries, including Automotive and Motorsport, Medical, Oil and Gas, Aerospace and Defensive, Nuclear, and more.

But don’t just take our word for it! Our clients have left some glowing testimonials. To read some of our testimonials, click here.

Contact Us If You’re Looking For Manufacturing Outsourcing Services!

Let's get started with your next project...