Sotek Engineering

CNC Cutting Service UK

Looking For Top-Quality CNC Cutting UK?

Contact Us!

At Sotek Engineering, we specialise in CNC cutting services tailored for a wide array of industries including automotive, motorsport, medical, oil and gas, aerospace, defence, and nuclear.

Our founding mission is to provide high-quality subcontract machining, design, reverse engineering, and repair services to all our valued clients. We take pride in crafting high-quality custom parts for their products, using the latest technology and strict quality control measures to ensure outstanding results.

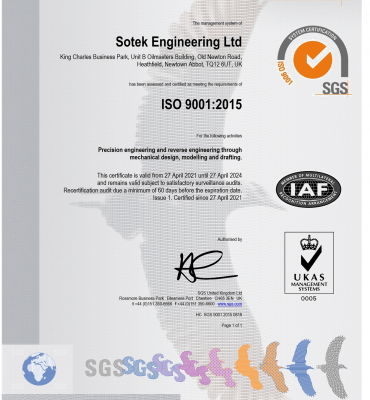

We’ve achieved full compliance with ISO 9001:2015 standards, which has helped us build a great reputation as a reliable CNC machining partner across various thriving sectors. This commitment to delivering exceptional quality is reflected in our excellent client satisfaction ratings and countless positive reviews.

CNC Cutting Service 1:

CNC Milling

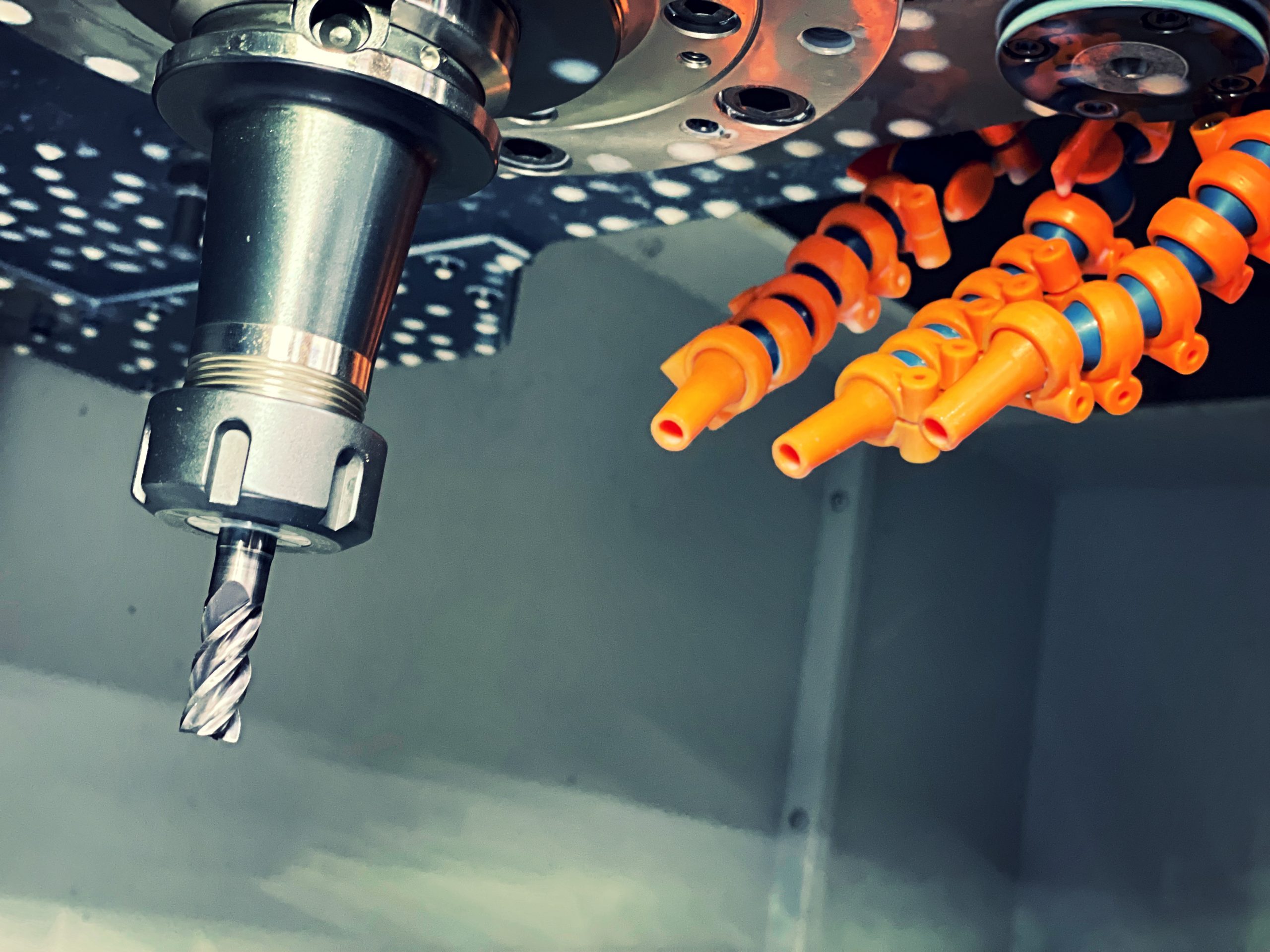

CNC milling is a machining method that uses a computer-controlled machine tool to craft precise and intricate parts from various materials, including metals, plastics, and composites.

The process starts by securely attaching the workpiece to a worktable. From there, the machine employs a rotating cutting tool to remove material according to specific design requirements.

This cutting tool can move in multiple directions — along the x, y, and z axes — enabling it to create a diverse array of shapes and dimensions with remarkable accuracy. It’s capable of producing complex features like holes, slots, pockets, and contours, all to high standards.

Thanks to advanced software and automation, CNC milling can achieve outstanding precision when creating intricate designs. Additionally, these machines can be equipped with different cutting tools, such as end mills, drills, and taps, allowing for a wide variety of milling applications.

The Types Of CNC Milling Machines

At Sotek Engineering, we offer a diverse range of CNC milling machines to meet varied manufacturing needs.

- Vertical Milling Machines: These feature a vertical spindle that operates on the up-and-down movement, allowing for precision along the X and Y axes.

- Horizontal Milling Machines: With a horizontal spindle, these machines can move side-to-side, efficiently working along the X and Z axes.

- 5-Axis Milling Machines: Ideal for creating intricate and detailed parts, these machines enable the cutting tool to manoeuvre across five different axes for maximum flexibility.

- Gantry Milling Machines: These machines utilise a fixed bridge that spans the workpiece, allowing the cutting tool to move across multiple axes for large-scale projects.

The Applications Of CNC Milling

CNC milling machines play a crucial role in many industries thanks to their impressive precision and capability to create high-quality products. They are most commonly used in sectors such as automotive, aerospace, medical, and defence, to name just a few.

The Benefits Of CNC Milling

CNC milling brings a lot of advantages to the manufacturing sector. Here are some of the key benefits:

- High precision standards

- Significant defect reduction

- Minimal waste

- Quicker, more efficient production rates

- Quick assembly

- Improved personnel safety

- Reduced energy consumption

- Lower production costs

CNC Cutting UK Service 2

CNC Turning

CNC Turning is a machining technique that creates cylindrical or conical parts using a computer-controlled lathe.

In this process, the workpiece is spun while a cutting tool, which is securely held in a tool turret, shapes it by moving along its surface. This method allows for precise crafting of the desired shape and size of the final product.

A lathe machine can perform multiple tasks such as facing, drilling, threading, and grooving. Similar to CNC Milling, CNC Turning works with a broad selection of materials—like metals, plastics, and composites—and is known for producing parts quickly and with great accuracy.

The Features Of CNC Turning Machines

Bar Feeder: The bar feeder is a handy device that automatically loads raw materials, like metal bars or tubes, into the CNC lathe machine. It helps in crafting long, cylindrical parts.

By holding several raw materials at once, the bar feeder streamlines the process and boosts productivity, eliminating the need for someone to load the materials manually.

Driven Tooling: Driven tooling is a feature that allows the CNC turning machine to produce intricate details on the workpiece, including holes and slots.

Using rotating cutting tools powered by a motor, driven tooling enables various operations like drilling, tapping, and milling to be carried out all in one go. This versatility makes it easier to achieve complex designs efficiently.

The Applications Of CNC Turning

CNC turning machines play a vital role across many manufacturing sectors, such as automotive, aerospace, medical, and defence. They bring numerous advantages to the table, including higher production efficiency, shorter lead times, and reduced costs.

The Benefits Of CNC Turning

- Quicker, more efficient production

- High precision standards

- Minimal waste

- Significant defect reduction

- Improved personnel safety

- Reduced energy consumption

- Lower production cost

- Flexible

About Sotek Engineering

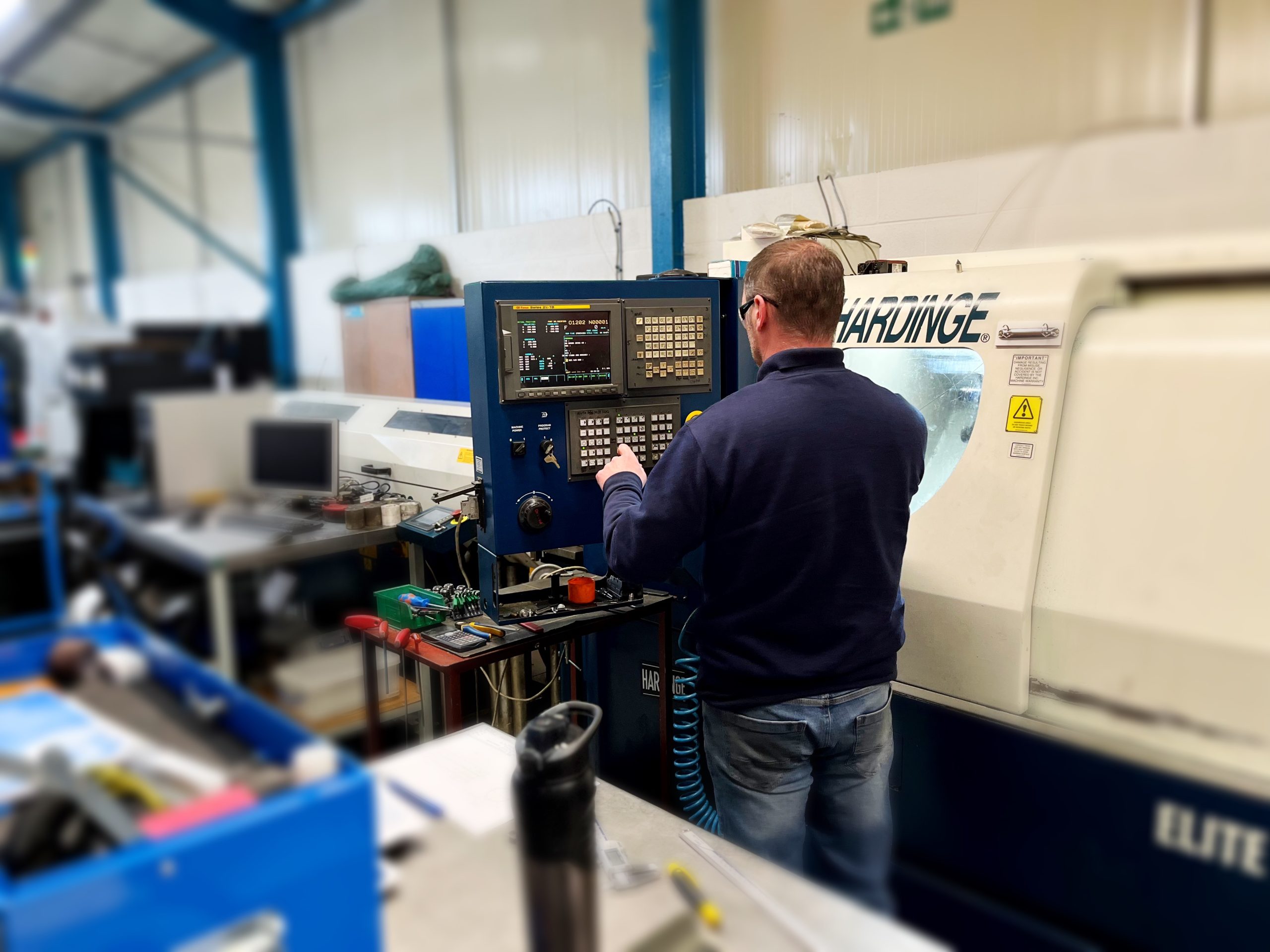

Sotek Engineering was founded in 2017 by Steve Brown and Oliver Cumbers, driven by a straightforward yet impactful vision: to provide premium-quality subcontract machining, design, reverse engineering, and repair solutions to businesses throughout the UK.

We take pride in being a reliable provider of CNC Turning services to many industries. By leveraging cutting-edge technology, strict quality control measures, and a strong commitment to exceptional customer service, we’ve built a reputation for delivering flawless products, every time.

Located in Newton Abbot, just off a major road that connects to the UK Motorway Network, we’re well-positioned to offer same-day or next-day deliveries whenever needed.

At Sotek Engineering, we provide a wide array of CNC services, including:

- CNC Routing

- CNC Milling

- Design

- Reverse Engineering

- Re-Engineering

Why Choose Us For CNC Cutting UK?

We’re thrilled to share that we’ve helped hundreds of happy clients—and that number keeps growing all the time!

With 15 years of experience in the industry, we’ve honed our skills to deliver high-quality products to a wide range of customers. Our commitment to precision is what sets us apart, making us a go-to supplier for companies with strict standards, including those in the Medical, Aerospace, and Defence sectors.

Thanks to our hard work and dedication, we’ve earned fantastic feedback from our clients. If you’d like to see what they have to say, just click here to read their testimonials!

Our Quality Control

At Sotek Engineering, we firmly believe that achieving top-notch results starts with having strict quality control measures in place. We’re dedicated to incorporating these quality principles into everything we do, which has helped us earn the trust of our valued customers.

We understand that our relationships with clients are built on a solid foundation of trust, and by prioritising quality control, we can keep all our promises and consistently deliver high-quality outcomes.

To ensure we maintain our standards, we use ISO 9001:2015 compliant quality management systems, conduct regular inspections, and apply diligent statistical process control (SPC) throughout our operations. If you want to know more about our quality control process, click here.

Contact Us If You’re Looking For A Top-Quality CNC Cutting Service UK!

Let's get started with your next project...