In industries ranging from aerospace to medical devices, precision engineering is essential to delivering high-quality, reliable, and innovative products. At Sotek Engineering, we specialize in precision engineering, offering expertise and cutting-edge technology to create components that meet the most stringent specifications. In this post, we’ll explore why precision engineering matters and how it drives performance and value across industries.

What is Precision Engineering?

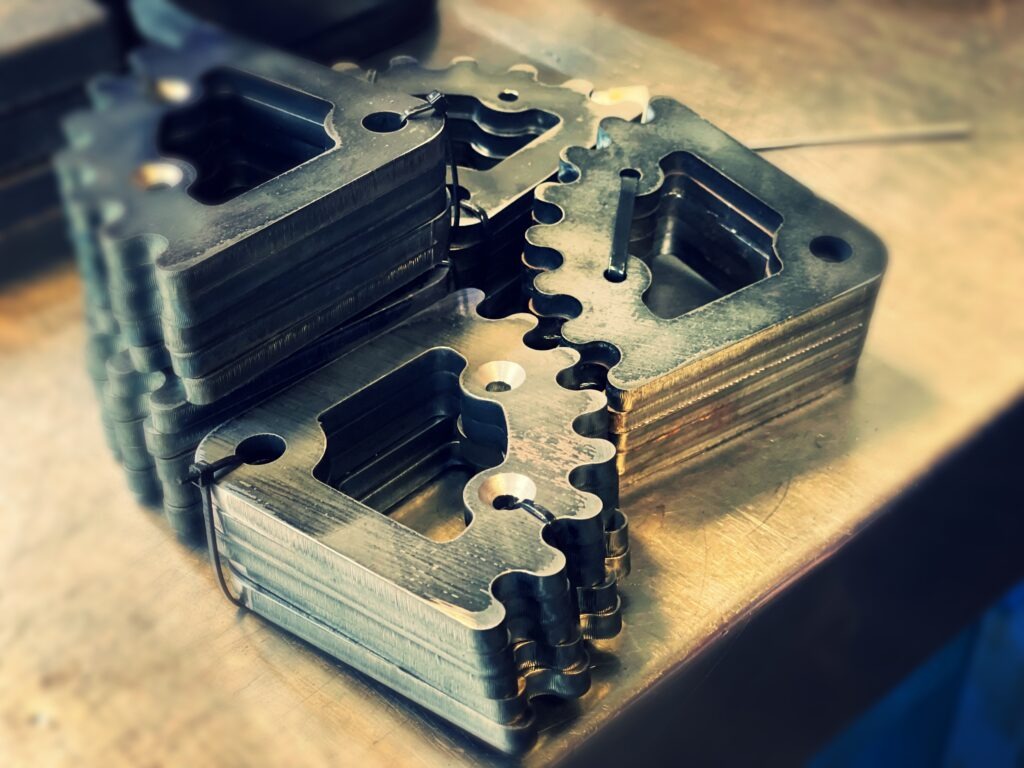

Precision engineering involves designing and manufacturing components with extremely tight tolerances, often within microns. This high level of accuracy is crucial when producing parts that must fit perfectly into larger assemblies, function reliably under stress, or meet rigorous industry standards. Precision engineering integrates advanced machinery, computer-aided design (CAD) software, and highly skilled professionals to achieve exact specifications consistently.

Why Precision Engineering Matters

Precision engineering impacts various aspects of product quality and performance. Here’s why it’s so valuable:

- Enhanced Product Quality and Reliability When components are engineered with precision, they meet specific quality standards, reducing the risk of defects and improving the longevity of the final product. This is especially important in fields like aerospace, automotive, and medical devices, where even a small deviation can affect functionality and safety.

- Greater Efficiency in Manufacturing By ensuring that each part is manufactured to exact specifications, precision engineering minimizes the need for rework or adjustments, leading to a more efficient production process. This reduces production time, optimizes resource use, and helps meet tight project deadlines.

- Cost Savings While precision engineering requires upfront investment in high-quality tools and technology, it often leads to significant long-term savings. Accurate manufacturing reduces waste, minimizes costly errors, and ensures products meet requirements the first time, reducing the need for additional labor and resources.

- Innovation and Customization Precision engineering allows for the creation of custom parts that meet unique requirements, supporting innovation across industries. Whether it’s designing lightweight parts for aerospace applications or developing custom components for specialized machinery, precision engineering is key to pushing the boundaries of what’s possible.

How Sotek Engineering Ensures Precision

At Sotek Engineering, we use state-of-the-art machinery, the latest software, and a team of experienced engineers to deliver consistent precision. Here are some ways we guarantee excellence in every project:

- Advanced CNC Machining: Our computer numerical control (CNC) machines provide unparalleled accuracy and repeatability, allowing us to produce parts with tight tolerances efficiently and consistently.

- Rigorous Quality Control: Each component undergoes multiple quality checks, from initial CAD designs to final inspection. This ensures every product meets our exacting standards and complies with industry requirements.

- Continuous Training: Our team of engineers and machinists are continually trained on the latest techniques and technologies in precision engineering. This keeps us ahead of industry standards and ensures our clients receive the highest quality products.

- Customer-Centric Approach: We work closely with clients to understand their specific needs and challenges, providing tailored solutions that align with their goals. This commitment to customer satisfaction is what makes Sotek Engineering a trusted partner in precision engineering.

Precision Engineering Applications

Precision engineering is essential in various sectors, each with unique demands for high-quality components. Here are just a few industries where precision engineering is transforming performance:

- Aerospace: In an industry where safety is paramount, precision-engineered components contribute to the reliability and efficiency of aircraft.

- Automotive: Precision parts ensure better vehicle performance, fuel efficiency, and safety.

- Medical Devices: High-precision components are critical in developing life-saving medical equipment that meets stringent regulatory requirements.

- Electronics: As devices become smaller and more complex, precision-engineered parts enable manufacturers to fit complex functionality into compact spaces.

Why Choose Sotek Engineering?

Precision engineering is about more than just meeting specifications—it’s about delivering quality, innovation, and value. At Sotek Engineering, we’re dedicated to helping clients achieve their goals through our commitment to precision, quality, and customer satisfaction. With our experience, resources, and passion for excellence, we’re here to support your project’s success from start to finish.

Let’s make precision work for you. Contact Sotek Engineering today to discuss how we can bring accuracy, quality, and efficiency to your next project.