Sotek Engineering

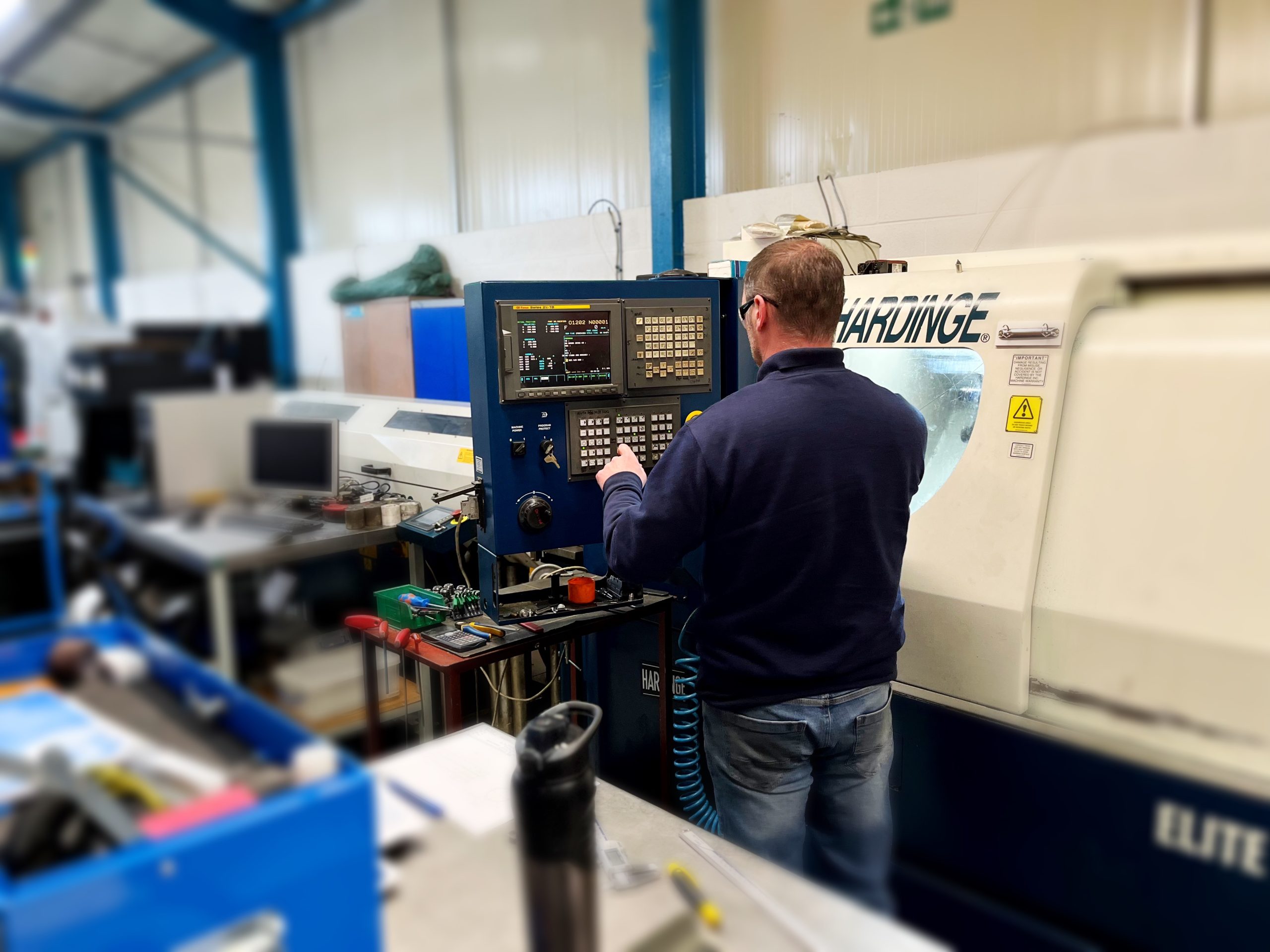

CNC Contract Manufacturing

Looking For Top-Quality CNC Contract Manufacturing?

Contact Us!

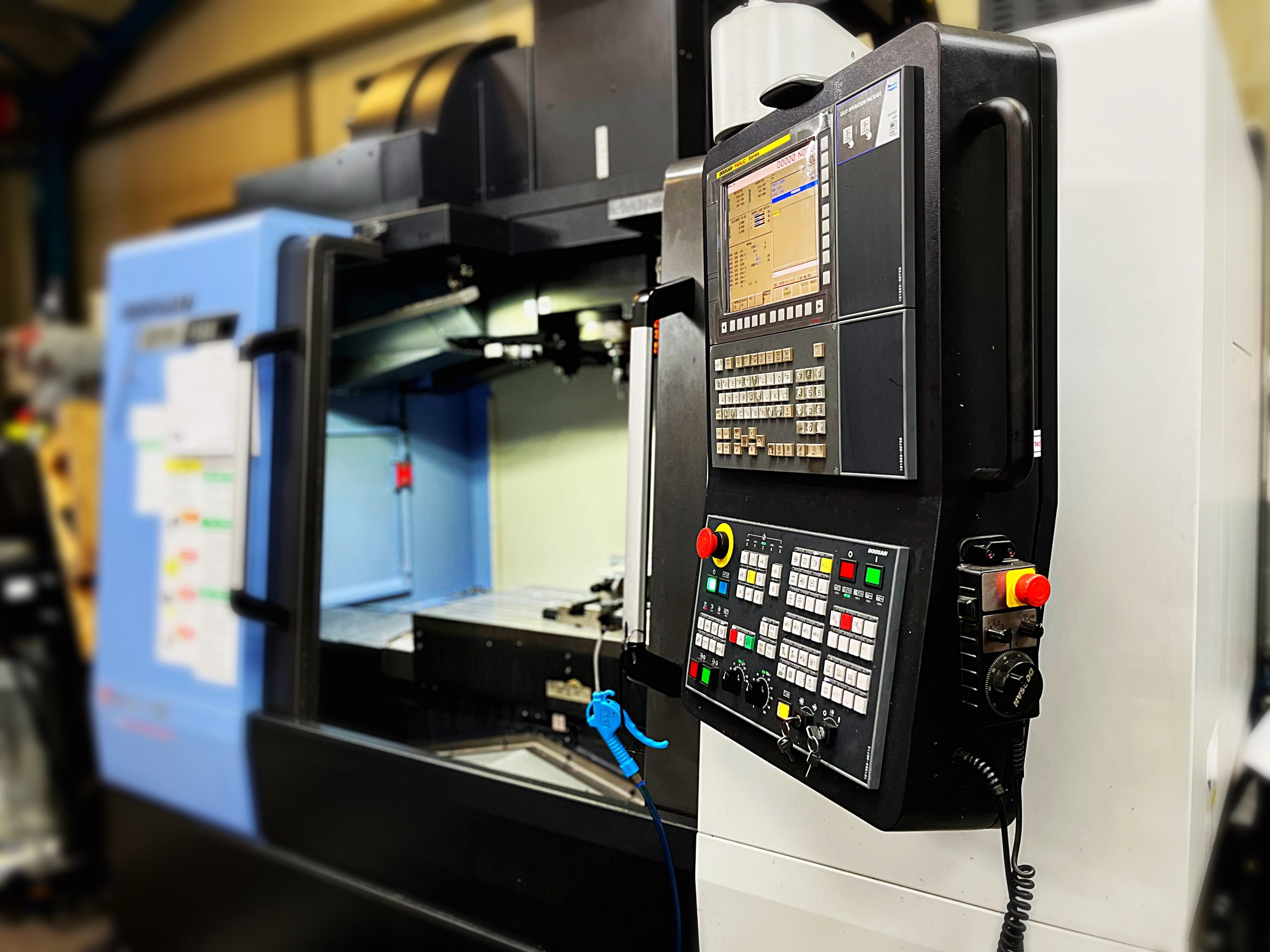

At Sotek Engineering, we specialise in providing high-quality CNC contract manufacturing. From CNC milling and CNC turning, to design for manufacturing, our range of services is designed to meet any requirement you may have.

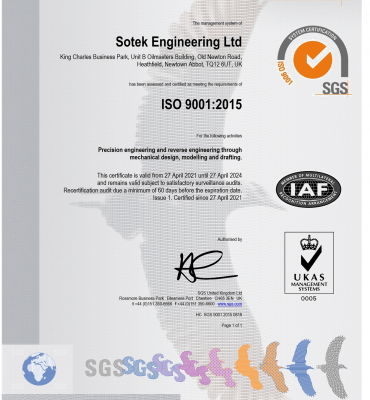

We’re committed to excellence and maintaining rigorous quality standards. By adhering to ISO 9001-2015 quality management systems, and conducting regular inspections with statistical process control (SPC), we ensure that every product we deliver meets the highest standards.

Our dedication to quality has earned us a great reputation as a trusted provider of CNC machining services across key industries, including Automotive, Motorsport, Medical, Oil and Gas, Aerospace, Defence, and Nuclear.

What Is CNC Machining?

CNC machining is a versatile manufacturing technique used to create a wide range of products from materials such as plastics, metals, acrylics, and wood.

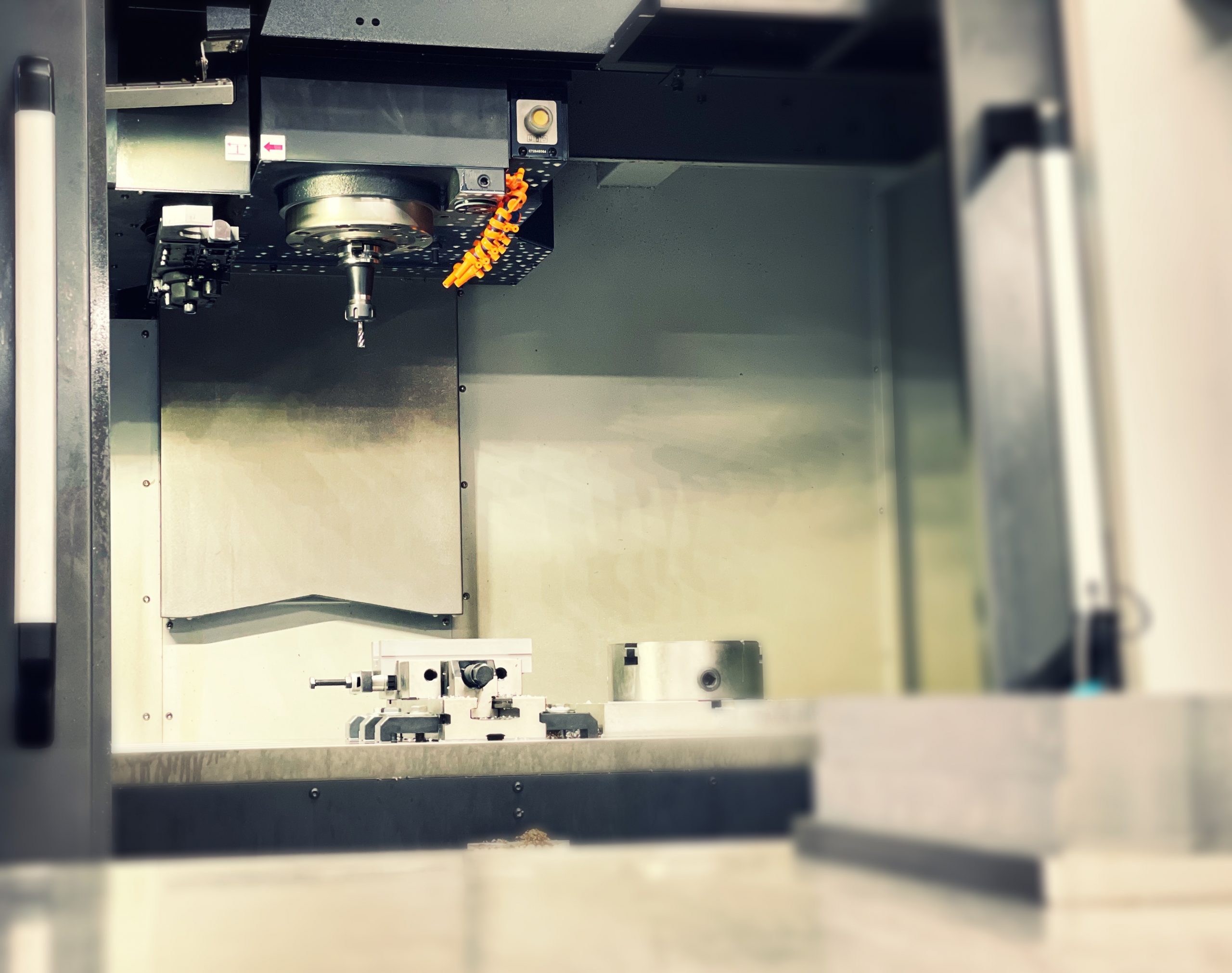

This subtractive process involves precisely cutting away material from a base workpiece using computer-controlled machinery to achieve the desired shape. Renowned for its accuracy and ability to handle complex designs, CNC machining is a popular choice across various industries.

There are two main methods in CNC machining: CNC Milling and CNC Turning.

CNC Milling is a fast and efficient method ideal for mass production. It uses a rotating cutting tool controlled by a CNC machine to carve material from a fixed workpiece on a table. This tool moves along multiple axes, allowing for the creation of intricate shapes like holes, slots, and contours.

CNC Turning, on the other hand, involves a rotating CNC lathe that holds the workpiece. The cutting tool shapes the material gradually until the desired cylindrical or conical form is achieved. This method is perfect for producing a wide range of cylindrical components with high precision.

The Advantages Of CNC Machining

CNC machining offers several key advantages for manufacturers:

- Accuracy: CNC machining delivers exceptional precision, surpassing methods like plastic injection moulding or 3D printing. This reliability is crucial for consistent results, particularly for prototyping and production runs.

- Complex Designs: Thanks to its ability to move along multiple axes, CNC machining excels at creating intricate designs with exacting standards. It often outperforms 3D printing in this area.

- Tight Tolerances: CNC machines can produce parts with very tight tolerances, exceeding the capabilities of plastic injection moulding and 3D printing.

- Plastic Compatibility: CNC machining can work with a variety of plastic polymers, such as Delrin (POM), Nylon, Acrylic, Teflon (PTFE), Polyether (Peek), and Ultra-High Molecular Weight Polyethylene (UHMW). This versatility makes it ideal for manufacturing plastic products.

- Defect Reduction: The precision of CNC machining significantly reduces defects, which improves the overall quality of the final products compared to other manufacturing techniques.

- Waste Reduction: By minimising defects, CNC machining also reduces waste, which leads to cost savings on material expenses for clients.

- Flexibility: CNC machining offers unmatched flexibility, allowing for the production of a wide range of shapes and complexities to meet diverse project requirements.

Our Commitment To Providing Top-Quality CNC Contract Manufacturing

At Sotek Engineering, our mission is straightforward but essential: to deliver outstanding results at sensible prices. Quality is at the heart of everything we do, and we uphold stringent standards across all our manufacturing processes. For instance, our ISO 9001-2015 compliant systems and regular inspections ensure that every product meets our high expectations.

Customer satisfaction is our top priority. We are dedicated to providing exceptional support and guidance, and we take pride in building strong relationships with all our clients. We serve a wide range of industries, including Automotive and Motorsport, Medical, Oil and Gas, Aerospace and Defence, and Nuclear, and we’re honoured to meet the needs of such discerning businesses.

Why Choose Us?

During our 15 years in the industry, we have served hundreds of satisfied clients!

Our extensive background has equipped us to deliver top-notch products to our diverse clientele. Renowned for our knack for producing flawlessly finished products, we’ve become the trusted supplier for companies demanding high standards of accuracy, particularly in the Medical, Aerospace, and Defence industries.

Thanks to our experience and unwavering dedication, we’ve earned consistent acclaim from our valued customers. To read our testimonials, click here.

Our Quality Control

At Sotek Engineering, we firmly believe that achieving high-quality results hinges on maintaining impeccable quality control standards. Our commitment extends to weaving quality control principles into every facet of our work, establishing the trust of our valued customers.

Recognising that our client relationships are rooted in confidence, we place customer satisfaction at the forefront. This strategic focus allows us to not only meet but consistently exceed expectations, delivering high-quality results every time.

To ensure our commitment to quality, we employ ISO 9001:2015 compliant quality management systems, conduct regular inspections, and employ diligent statistical process control (SPC) throughout our operations. To learn more about our commitment to quality control, go here.

About Sotek Engineering

Established in 2017 by Steve Brown and Oliver Cumbers, Sotek Engineering combines a highly experienced team with advanced CNC technology and rigorous quality control. Our mission is clear: to meet the needs of UK businesses by providing top-quality machining, design, reverse engineering, and repair solutions.

Situated in Newton Abbot, conveniently close to the main road connecting to the UK motorway network, we pride ourselves on swift delivery – often within the same or next day.

Our CNC services encompass a broad range, including CNC Machining, CNC Routing, Design, Reverse Engineering, and Re-Engineering, among others.

Contact Us If You’re Looking For CNC Contract Manufacturing!

Let's get started with your next project...